Method for the homogeneous non-contact cooling of hot, non-endless surfaces and device therefor

A cooling device, non-contact technology, applied in the direction of workpiece cooling device, workpiece heating device, quenching device, etc., can solve problems such as becoming problematic, unsuitable, expensive cooling system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] One possible implementation will be described below.

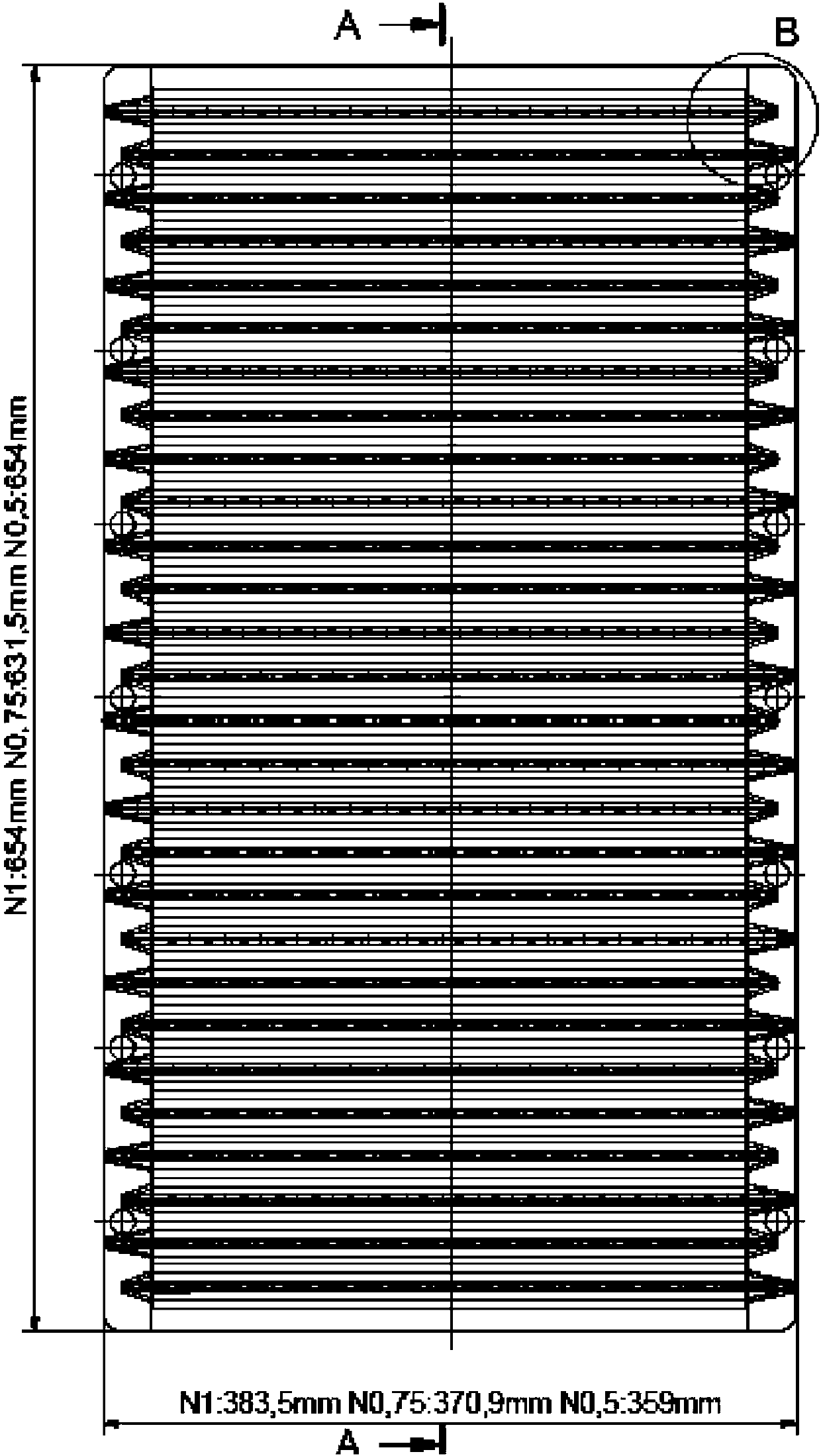

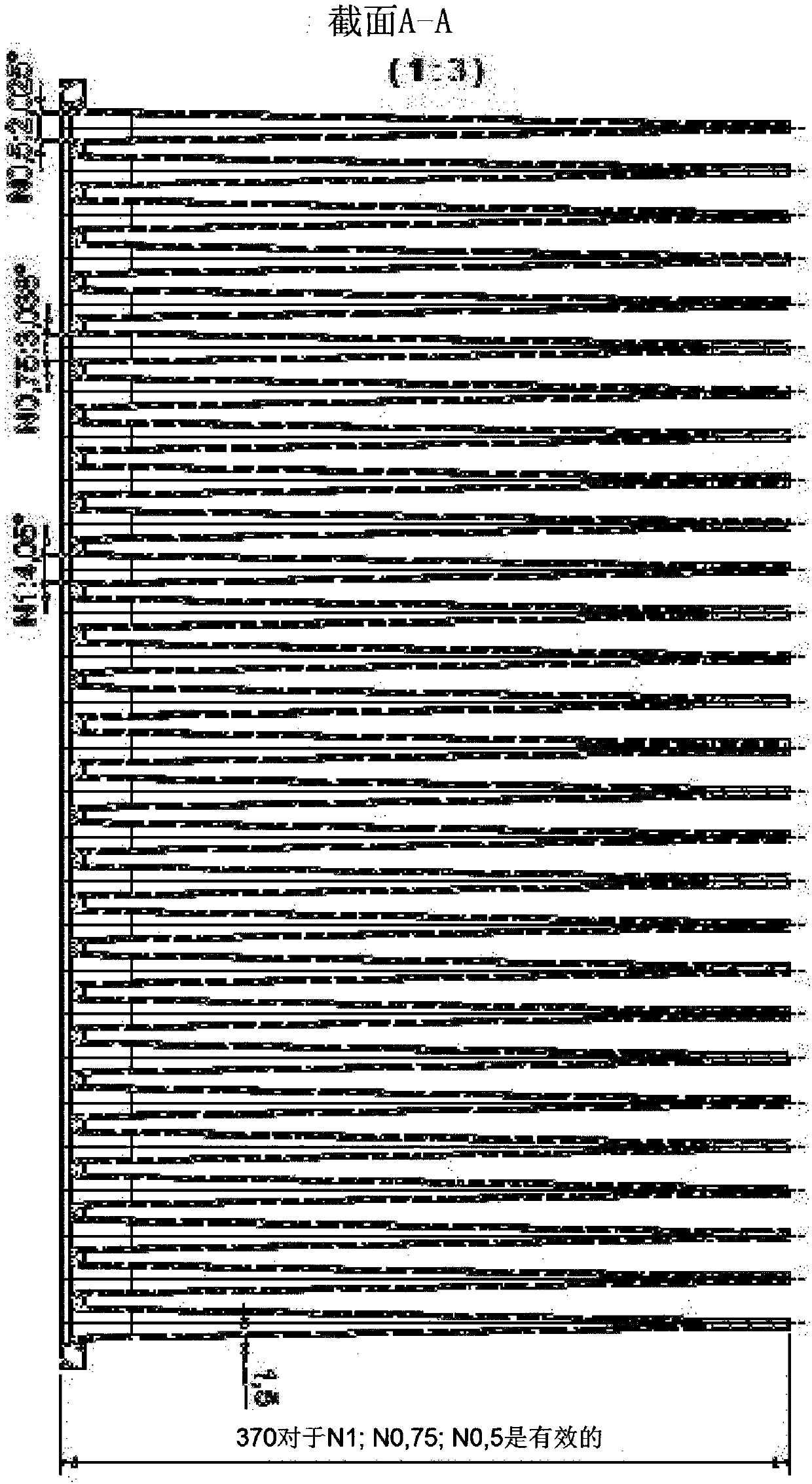

[0038] The cooling device 1 according to the invention has at least one cooling blade 2 . The cooling blade 2 is realized in the form of an elongated airfoil and has a cooling blade base 3, two cooling blade broadsides 4 extending away from the cooling blade base, two cooling blade narrowsides 5 connecting the cooling blade broadsides, and the free nozzle edge 6 .

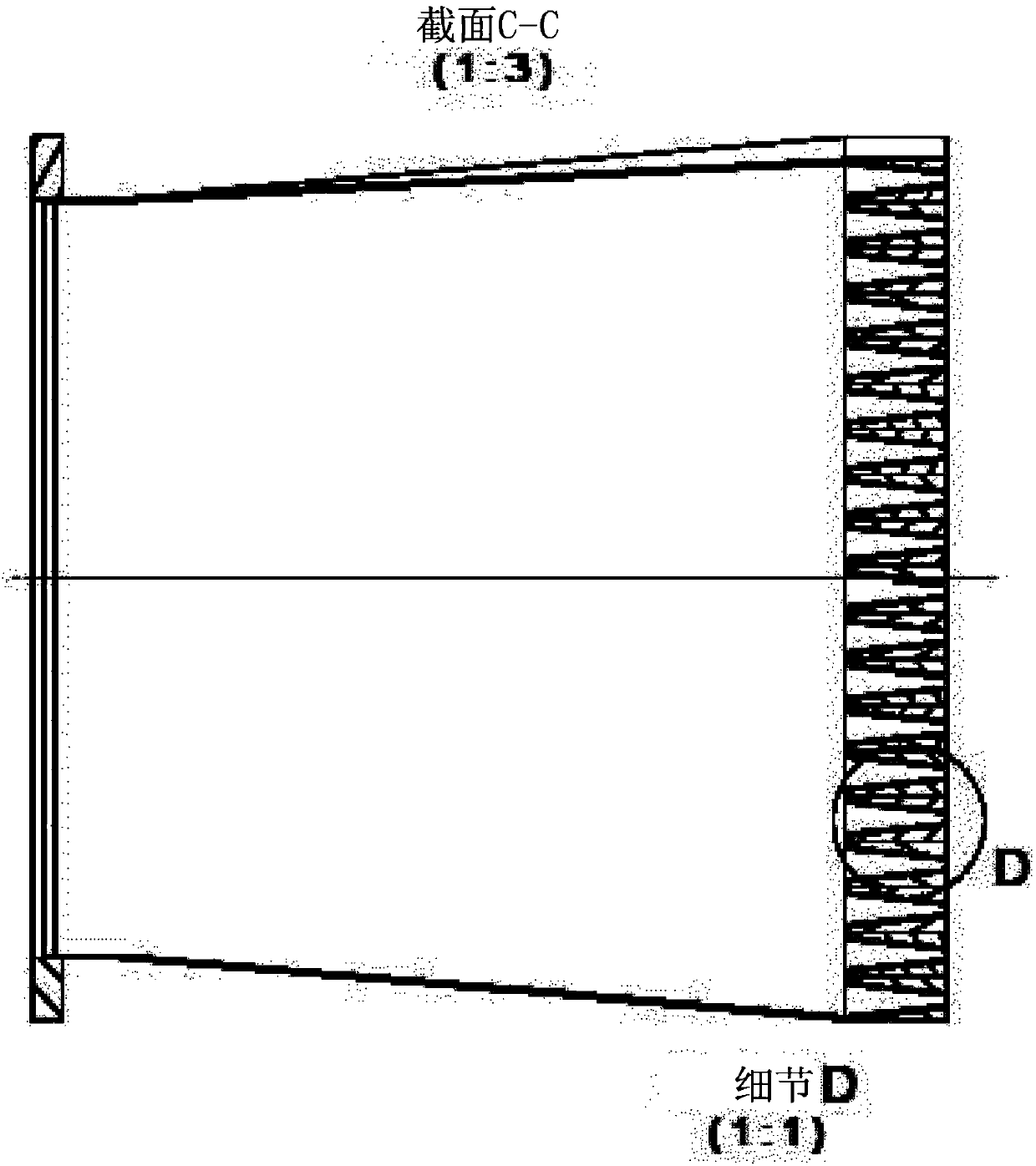

[0039] The cooling vane 2 is realized as a hollow body with a cooling vane cavity 7 ; Using the cooling blade base 3, the cooling blades are inserted into the cooling blade frame 8; and the cooling blade frame 8 can be placed on the hollow fluid supply tank.

[0040] The area of the nozzle edge 6 is provided with a plurality of nozzles or openings which reach into the cavity 7 and thus allow fluid to flow out of the cavity to the outside through the nozzle 10 .

[0041] Nozzle ducts 11 extend from the nozzles into the chamber 7 , spatially separatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com