Methods and systems for engine fueling

A fuel supply and engine technology, applied to combustion engines, engine control, machines/engines, etc., can solve problems such as difficulty in starting the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

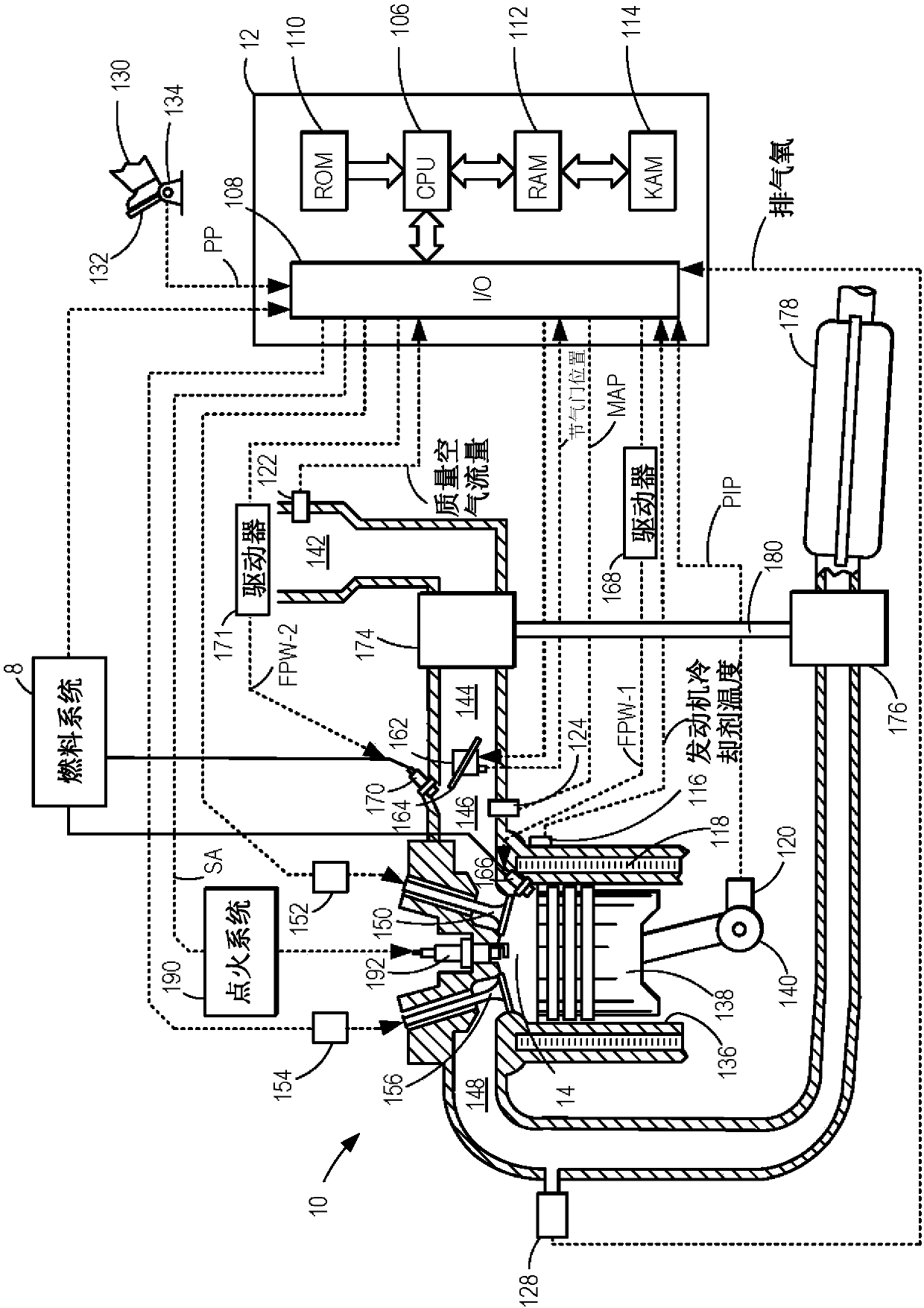

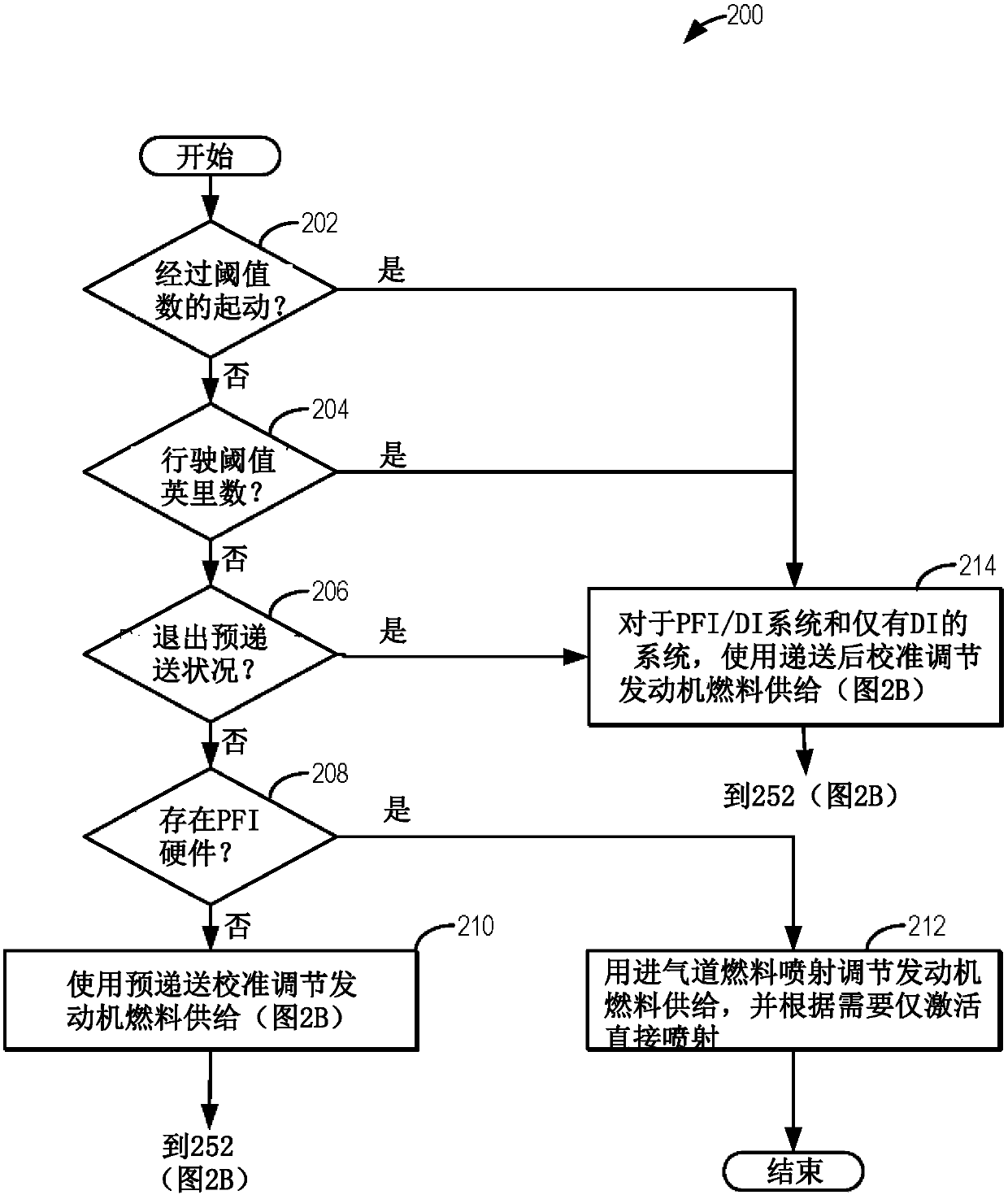

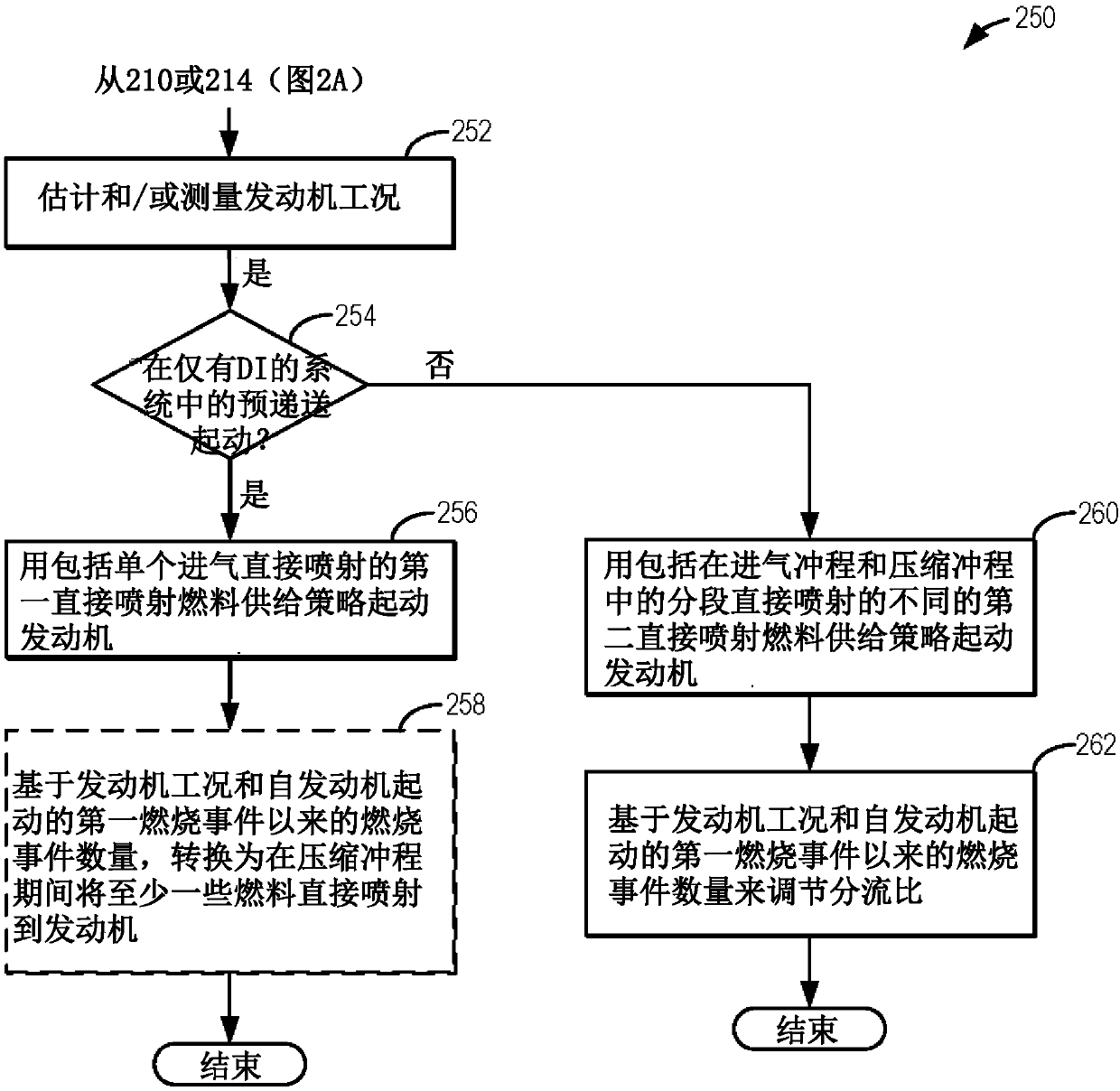

[0012] The following description relates to methods for adjusting fuel injection strategies to reduce such figure 1 Systems and methods for in-engine soot emissions in an engine system. The engine controller can be configured to execute control routines such as, Figure 2A An example routine of ) to determine a fueling strategy based on a single fueling capability or a dual fueling capability of an engine system. In engine systems that include port fuel injectors (PFI) and direct injectors (DI), while the vehicle is still in the assembly plant, the engine controller can fuel the engine with the PFI while intermittently enabling the DI, as Figure 2A shown. However, in engine systems that include only direct injectors, the engine controller may be configured to execute control routines such as, Figure 2B Example routine of ) to operate with a single intake stroke direct injection strategy during engine starts where there is a high propensity for spark plug fouling, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com