Method for synthesizing three-dimensional ordered double-mesoporous SBA-15 materials high in mesoporous size, adjustable in pore volume and highly polymerized in pore wall

A three-dimensional ordered, double mesoporous technology, used in chemical instruments and methods, molecular sieves and base exchange compounds, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

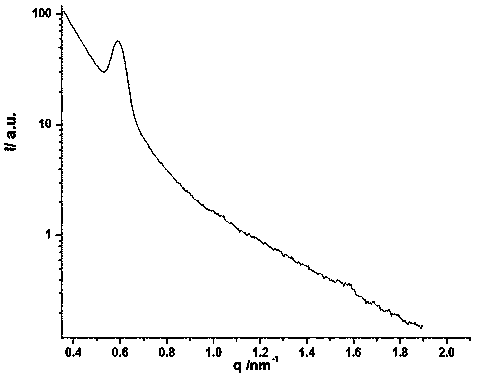

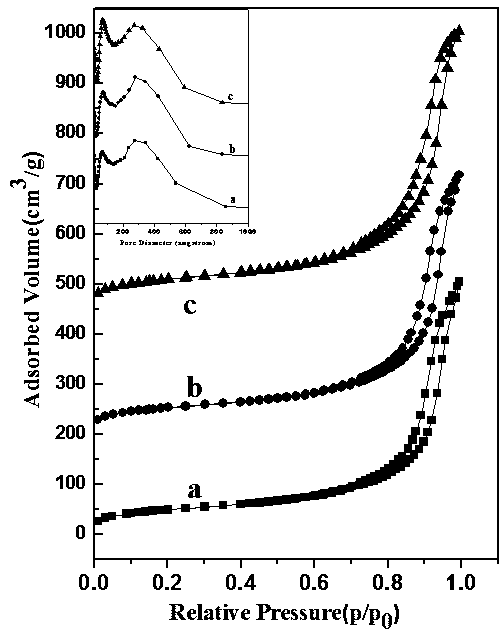

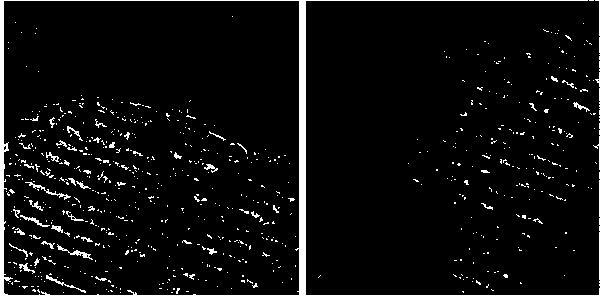

Image

Examples

Embodiment 1

[0021] Dissolve 0.8g P123 in 25mL deionized water and 3mL hydrochloric acid (10M) mixed solution, add 2.4mL tetraethyl orthosilicate (TEOS) under stirring, and stir at 40°C for 2h, add inorganic salt (KCl) 0.01mol, Continue to stir at 40°C for 20h, put it into a polytetrafluoroethylene-lined stainless steel reactor and react at 180°C for 24h, take it out, cool and filter, wash, dry, and calcinate at 550°C for 4h to remove the template preparation. A three-dimensional ordered double mesoporous SBA-15 material was obtained.

Embodiment 2

[0023] Dissolve 0.8g of P123 in 25mL of deionized water and 3mL of hydrochloric acid (10M) mixture, add 2.4mL of tetraethyl orthosilicate (TEOS) under stirring, and stir at 40°C for 2h, add inorganic salt (MgCl 2 ) 0.01mol, continue to stir at 40°C for 20h, put it into a polytetrafluoroethylene-lined stainless steel reactor and react at 180°C for 24h, take it out, cool and filter, wash, dry, and calcinate at 550°C for 4h to remove The three-dimensional ordered double mesoporous SBA-15 material was prepared by removing the templating agent.

Embodiment 3

[0025] Dissolve 0.8g of P123 in 25mL of deionized water and 3mL of hydrochloric acid (10M) mixture, add 2.4mL of tetraethyl orthosilicate (TEOS) under stirring, and stir at 40°C for 2h, add inorganic salt (AlCl 3 ) 0.01mol, continue to stir at 40°C for 20h, put it into a polytetrafluoroethylene-lined stainless steel reactor and react at 180°C for 24h, take it out, cool and filter, wash, dry, and calcinate at 550°C for 4h to remove The three-dimensional ordered double mesoporous SBA-15 material was prepared by removing the templating agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com