Offshore wind-power maintenance buffer landing and berthing device and application method thereof

An offshore wind power and boarding technology, which is applied in transportation and packaging, cargo handling equipment, ships, etc., can solve problems such as the difficulty of operation and maintenance ships getting close to wind turbines, the threat to the lives of operation and maintenance personnel, and the reduction of operation and maintenance efficiency. Small size, reduced device weight, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

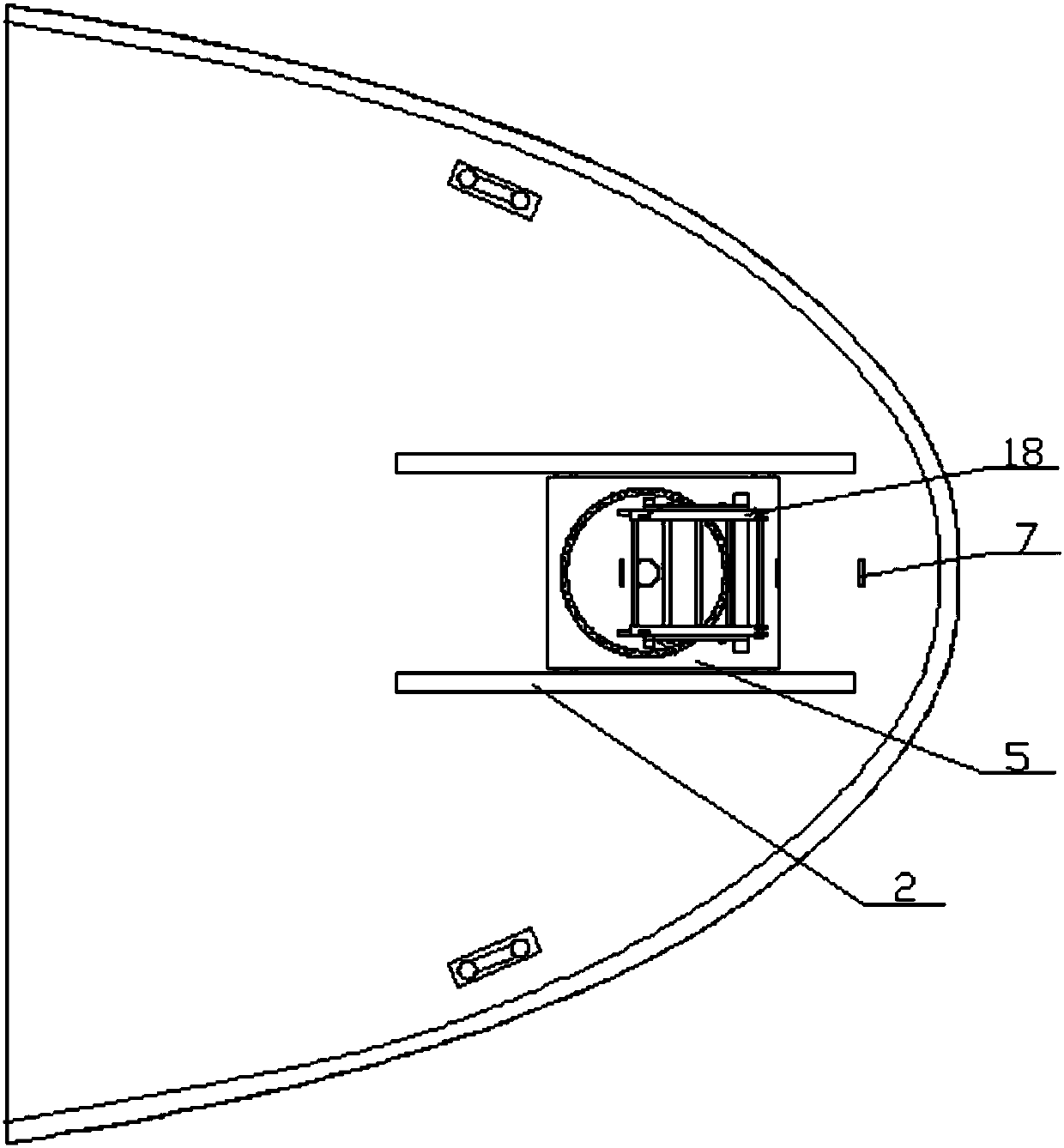

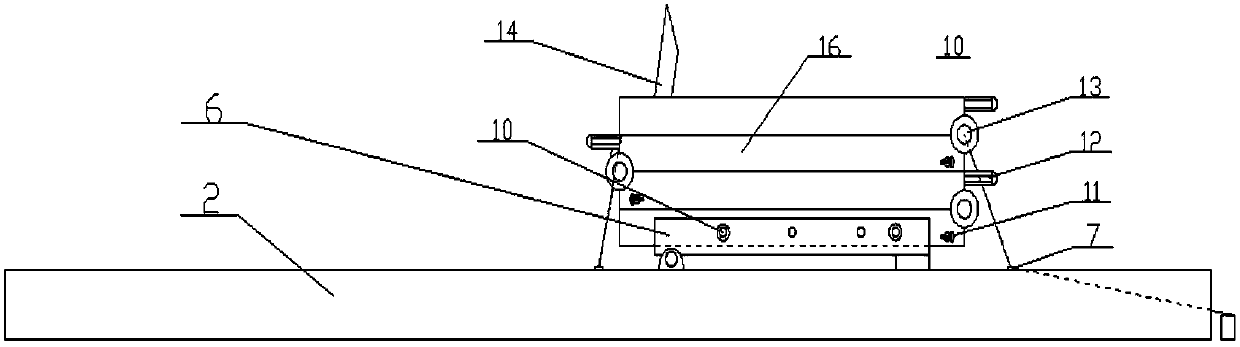

[0033] Embodiment: a buffer landing device for offshore wind power maintenance, such as figure 1 , 2 As shown, it includes a base 5 installed on the bow deck and a landing ladder whose bottom end is fixed on the base 5 .

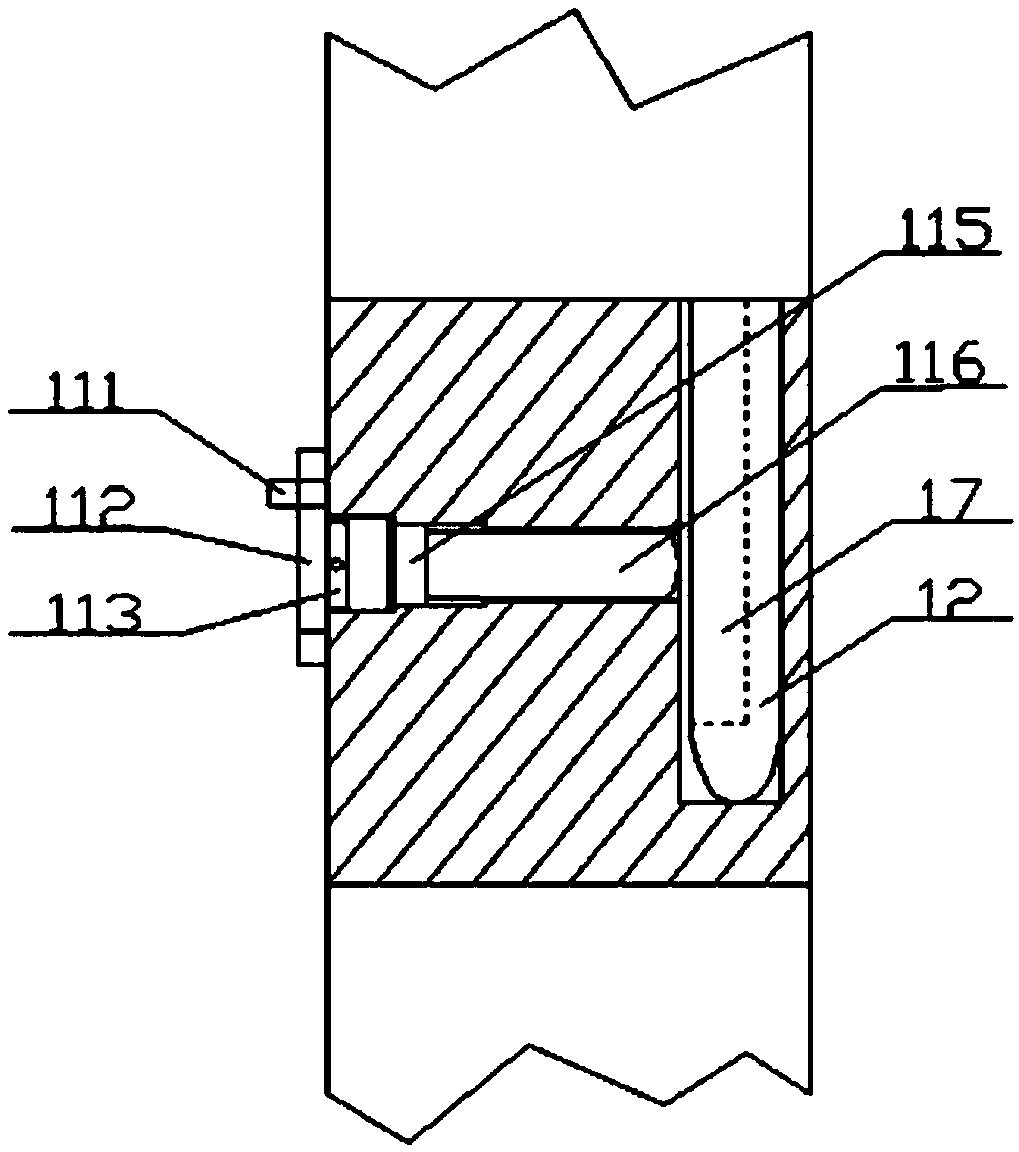

[0034] The landing ladder is composed of a section of ladder beams 16, and the connection form between the ladder beams 16 is hinged. The ladder beams 16 can rotate around the hinged end 13 with a certain degree of freedom to realize folding or straightening. The two connected ladder beams 16 are respectively provided with corresponding locking devices and buckling devices at the connecting ends, that is to say, the two ends of a ladder beam 16 are respectively provided with locking devices and buckling devices, and the adjacent The two ends of the ladder beam 16 are oppositely provided with buckle devices and locking devices, so that the ladder beams 16 can be connected in sequence and opened into a straight line and locked to ensure that the ladder beams ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com