Workpiece locating and clamping equipment

A technology for clamping equipment and workpieces, which is applied to metal processing equipment, positioning devices, metal processing machinery parts, etc., and can solve problems such as unfastened clamping, affecting processing accuracy, and inability to stably clamp fixed chucks and fixed fixtures. , to achieve the effect of stable work, not easy to be blocked, and simple fixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

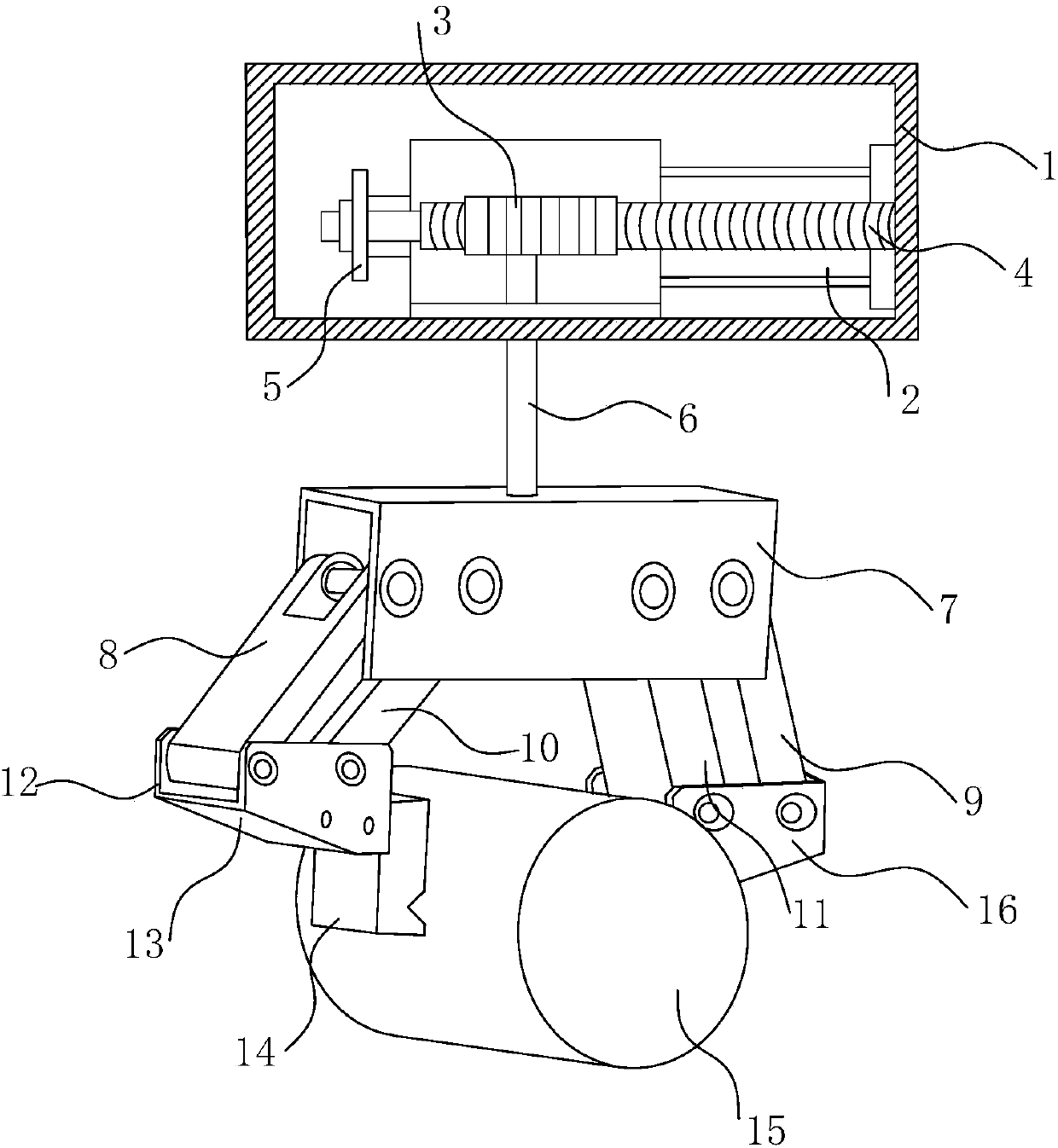

[0026] refer to Figure 1 ~ Figure 2 As shown: a workpiece positioning and clamping device, including a housing 1, the housing 1 is provided with an active driving mechanism, and also includes a driven driving mechanism driven by the active driving mechanism, and the driven driving mechanism drives the clamping Mechanism action; the active drive mechanism includes a cylinder 2, a drive rack 4 driven by the cylinder 2, and a drive gear 3 meshed with the drive rack 4; the cylinder 2 and the drive rack 4 are fixed on the connecting frame 5.

[0027] The driven drive mechanism includes a screw rod 6 connected to the driving gear 3, the first driven gear 17 and the second driven gear 18 are meshed on both sides of the screw rod 6 respectively; the driven drive mechanism is arranged in the fixed frame 7 , the screw rod 6 runs through the fixed frame 7 and is connected with the driving gear 3, and the fixed frame 7 is also provided with a left drive arm 10, a right drive arm 10 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com