Method for immobilizing natural antibacterial agent

A technology of natural antibacterial agents and carrier materials, applied in antibacterial drugs, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve problems such as lack of mature application technologies, achieve economical and feasible process paths, wide sources, and solve mildew change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

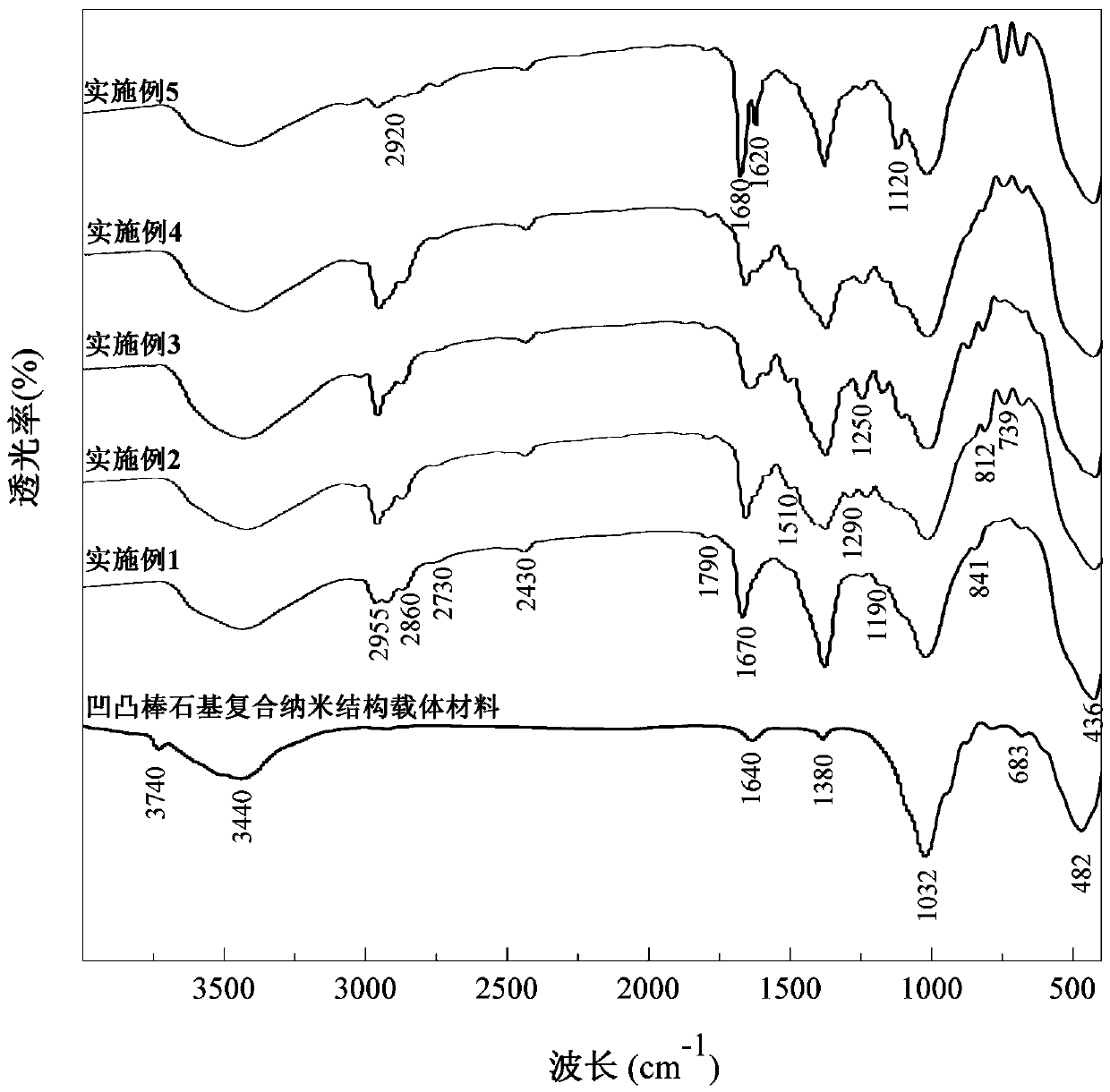

Embodiment 1

[0022] Example 1: Use high-speed stirring to prepare a suspension of attapulgite with a mass fraction of 2%, add zinc nitrate with a mass fraction of 10% to the dispersion, stir for 30 minutes, and let stand for 6 hours; then add the mass fraction dropwise to the system under mechanical stirring 2.5% sodium hydroxide solution until the zinc ions in the solution are completely deposited, centrifuged, dried, and calcined to obtain attapulgite-based composite nanostructure carrier materials; with the assistance of 300W ultrasonic waves, disperse 20% of its mass fraction in ethanol aqueous solution The carrier material and its mass fraction of 10% citral, the ratio of alcohol to water is 5:5; then shake in a constant temperature shaking box at 37°C for 24h, the mixture is centrifuged, dried at 60°C, ground, passed through a 200-mesh sieve, and packaged , to obtain attapulgite-based composite nanostructure immobilized natural antibacterial agent.

Embodiment 2

[0023] Embodiment 2: Adopt high-speed stirring to prepare a suspension of attapulgite with a mass fraction of 4%, add zinc chloride with a mass of 15% to the suspension, stir for 50min, and let stand for 3h; then add mass fraction to the system dropwise under mechanical stirring fraction of 5% sodium hydroxide solution until the zinc ions in the solution are completely deposited, centrifuged and dried to obtain the attapulgite-based composite nanostructure carrier material; The carrier material and thymol with a mass fraction of 20%, the ratio of alcohol to water is 6:4; then shake in a constant temperature shaking box at 37°C for 18h, the mixture is centrifuged, dried at 45°C, ground, passed through a 200-mesh sieve, and packaged. Attapulgite-based composite nanostructures were obtained to immobilize natural antibacterial agents.

Embodiment 3

[0024] Example 3: Using high-speed stirring to prepare a suspension of attapulgite with a mass fraction of 6%, adding zinc sulfate with a mass fraction of 20% to the suspension, stirring for 40min, and standing for 5h; then adding the mass fraction dropwise to the system under mechanical stirring 8% sodium hydroxide solution until the zinc ions in the solution are completely deposited, centrifuged and dried to obtain the attapulgite-based composite nanostructure carrier material; disperse the carrier with a mass fraction of 20% in ethanol aqueous solution under the assistance of 450W ultrasonic The material and its carvacrol with a mass fraction of 40%, the ratio of alcohol to water is 7:3; then shake in a constant temperature shaking box at 37°C for 18h, the mixture is centrifuged, dried at 45°C, ground, passed through a 200-mesh sieve, and packaged. Attapulgite-based composite nanostructures were obtained to immobilize natural antibacterial agents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com