Square billet rolling starting temperature acquisition and data processing method

A technology of starting rolling temperature and data processing, applied in the field of steel rolling, which can solve problems such as low starting rolling temperature, interference with temperature acquisition accuracy, and inability to rule out the influence of billet temperature, so as to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The invention discloses a billet start-rolling temperature acquisition and data processing method, including determination of temperature acquisition position, determination of effective acquisition temperature range, and effective temperature data processing.

[0019] A kind of square billet, size is 150mm (height) * 150mm (width) * 15700mm (length), and its rolling-starting temperature acquisition and data processing method are as follows:

[0020] 1. Three pyrometers (number Ⅰ, Ⅱ, Ⅲ) are arranged in a row and placed between the dephosphorization machine and 1# rolling mill, and the distance from 1# rolling mill is 0.5m.

[0021] 2. The three pyrometers correspond to the upper part (corresponding to number Ⅰ pyrometer), middle (corresponding to number Ⅱ pyrometer) and lower position (corresponding to number Ⅲ pyrometer) of the blank side (length×height, 15700mm×150mm).

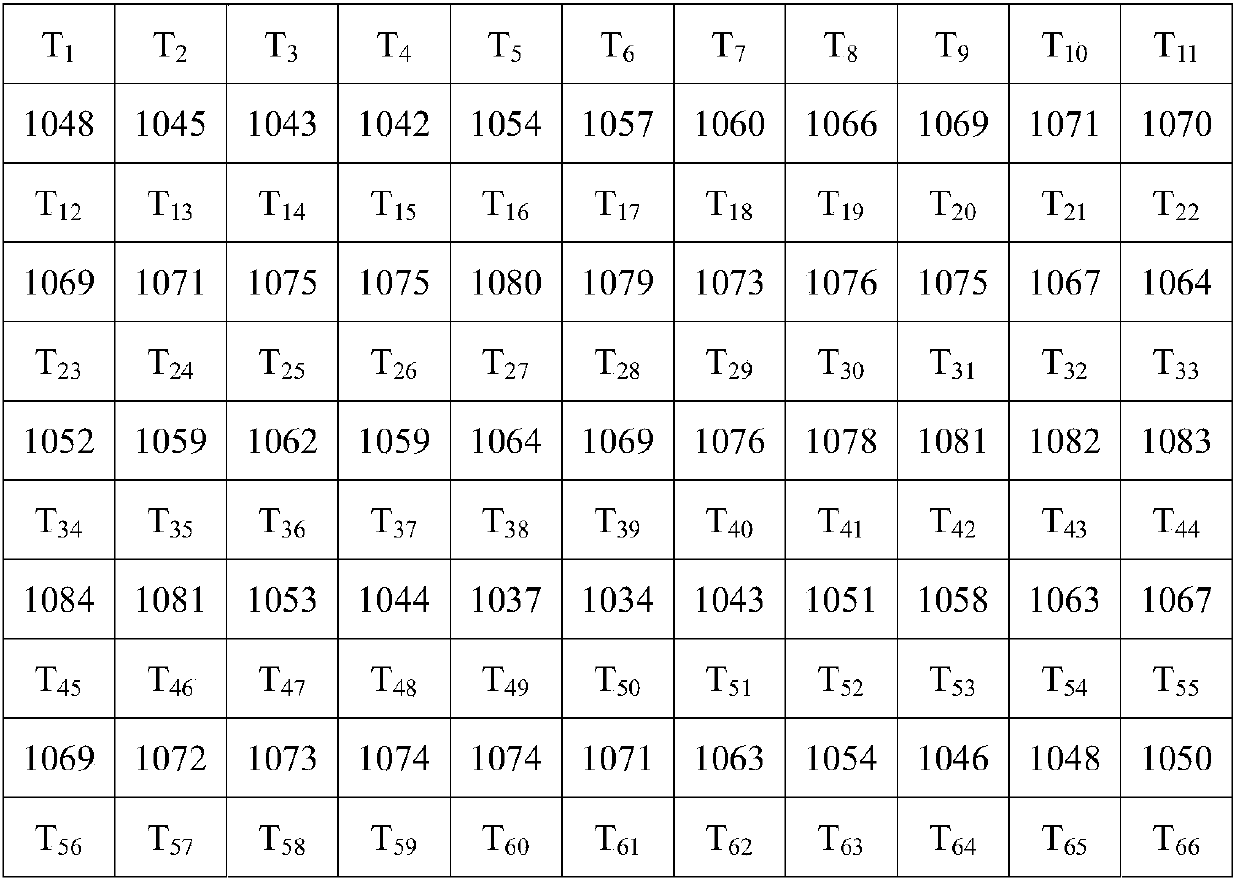

[0022] 3. The temperature data collected by the three pyrometers are shown in the table below:

...

Embodiment 2

[0041] The invention discloses a billet start-rolling temperature collection and data processing method, including determination of temperature collection position, determination of effective collection temperature range and processing of effective temperature data.

[0042] A kind of square billet, size is 300mm (height) * 390mm (width) * 5500mm (length), its rolling-starting temperature acquisition and data processing method are as follows:

[0043] 1. Three pyrometers (number Ⅰ, Ⅱ, Ⅲ) are arranged in a row and placed between the dephosphorization machine and 1# rolling mill, and the distance from 1# rolling mill is 0.5m.

[0044] 2. The three pyrometers correspond to the upper part (corresponding to number Ⅰ pyrometer), middle (corresponding to number Ⅱ pyrometer), and lower position (corresponding to number Ⅲ pyrometer) of the side of the billet (length×height, 5500mm×300mm).

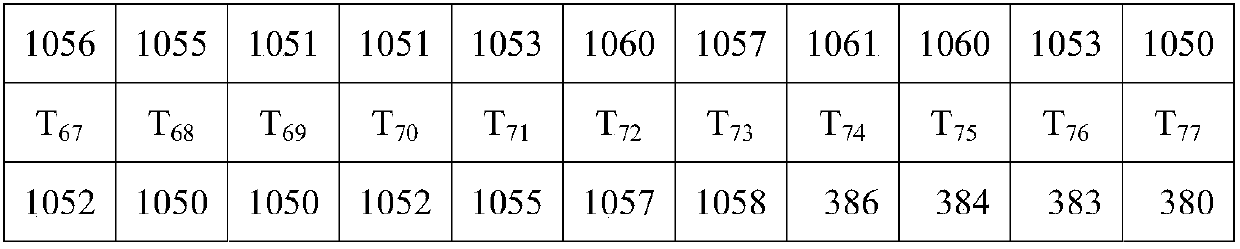

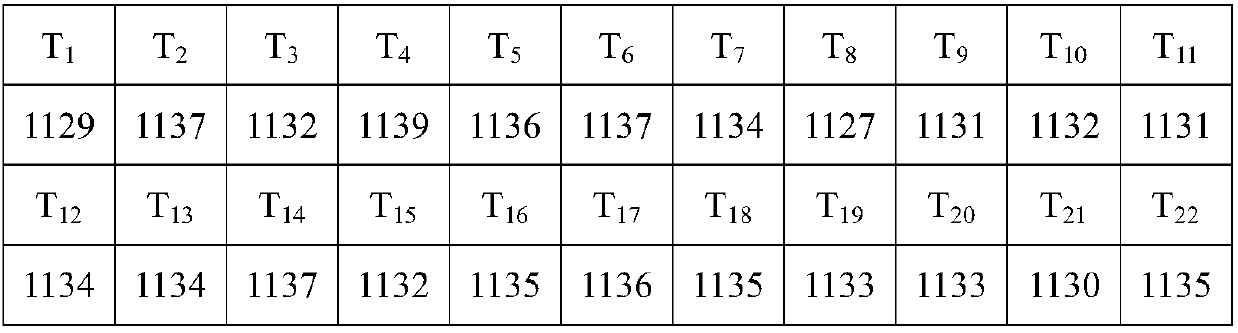

[0045] 3. The temperature data collected by the three pyrometers are shown in the table below: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com