Clean production process for using waste paper boxes to produce corrugating medium paper

A corrugated medium paper, clean production technology, applied in papermaking, paper machine, paper recycling, etc., can solve the problems of high cost and waste of resources, and achieve low production cost, saving production resources, good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

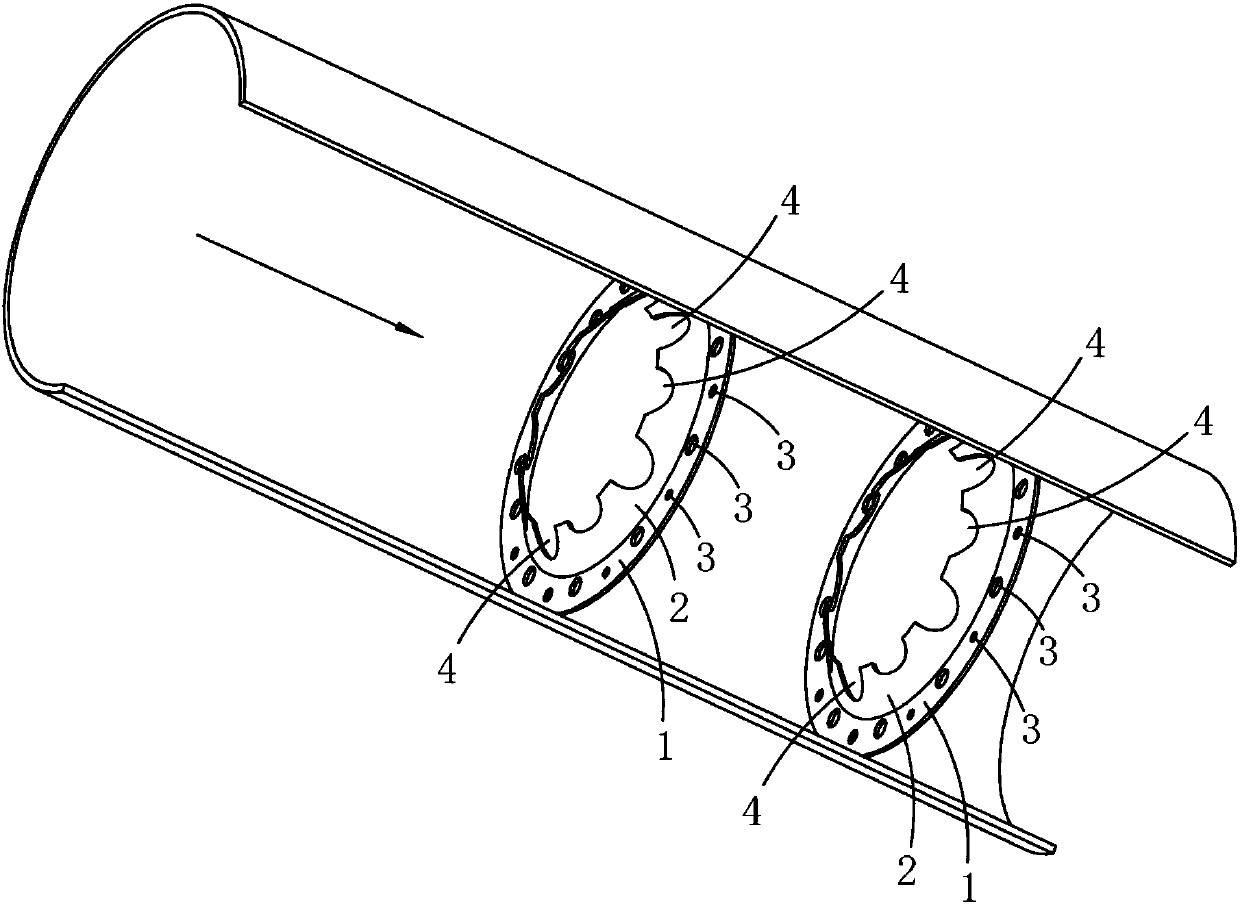

Image

Examples

Embodiment 1

[0028] A clean production process for producing corrugated medium paper using waste paper boxes,

[0029] In the leather fiber slurry pulping step, the recycled leather is pulped by a pulper, and then through the high-concentration deslagging step, the rough screening step, the low-concentration deslagging step, the fine screening step and the concentration step in sequence, to make a suitable Leather fiber pulp for papermaking, the pulping concentration of leather fiber pulp is controlled at 7-8%;

[0030] In the stripping step, the waste paper box is continuously conveyed through the conveyor belt, and the waste paper box is cut into strips by the slitting machine;

[0031] In the step of pulping waste paper, the waste paper box cut into strips is put into a large pulper, and the pulping is completed in the large pulper;

[0032] In the step of removing impurities and slag, the light slag floating on the upper layer of the large pulper is salvaged through the salvage net, a...

Embodiment 2

[0042] A clean production process for producing corrugated medium paper using waste cardboard boxes. The main steps, process parameters and advantages of this embodiment are the same as those of Embodiment 1, and will not be repeated here. The difference is that it includes the following steps,

[0043] Leather fiber slurry pulping step;

[0044] strip step;

[0045] waste paper pulping step;

[0046] Impurities and slag removal steps;

[0047] screening purification steps;

[0048] In the step of mixing petrochemical additives, the pure slurry is transported to the petrochemical reactor through the delivery pipeline, and the petrochemical additives are continuously and quantitatively injected at the turning point in the middle of the delivery pipeline. The flow rate of the pure slurry in the delivery pipeline with an inner diameter of 20-22cm is controlled at 8-10 m / min, the injection speed of petrochemical additives is 180-200 g / min, petrochemical additives include polyar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com