Clothing tailoring table

A cutting table and clothing technology, applied in the cutting of textile materials, textiles and papermaking, mechanical cleaning, etc., can solve the problems of time-consuming, laborious and low cutting efficiency, and achieve the effects of ensuring cutting quality, realizing quantitative cutting, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further detailed explanation through specific implementation mode below:

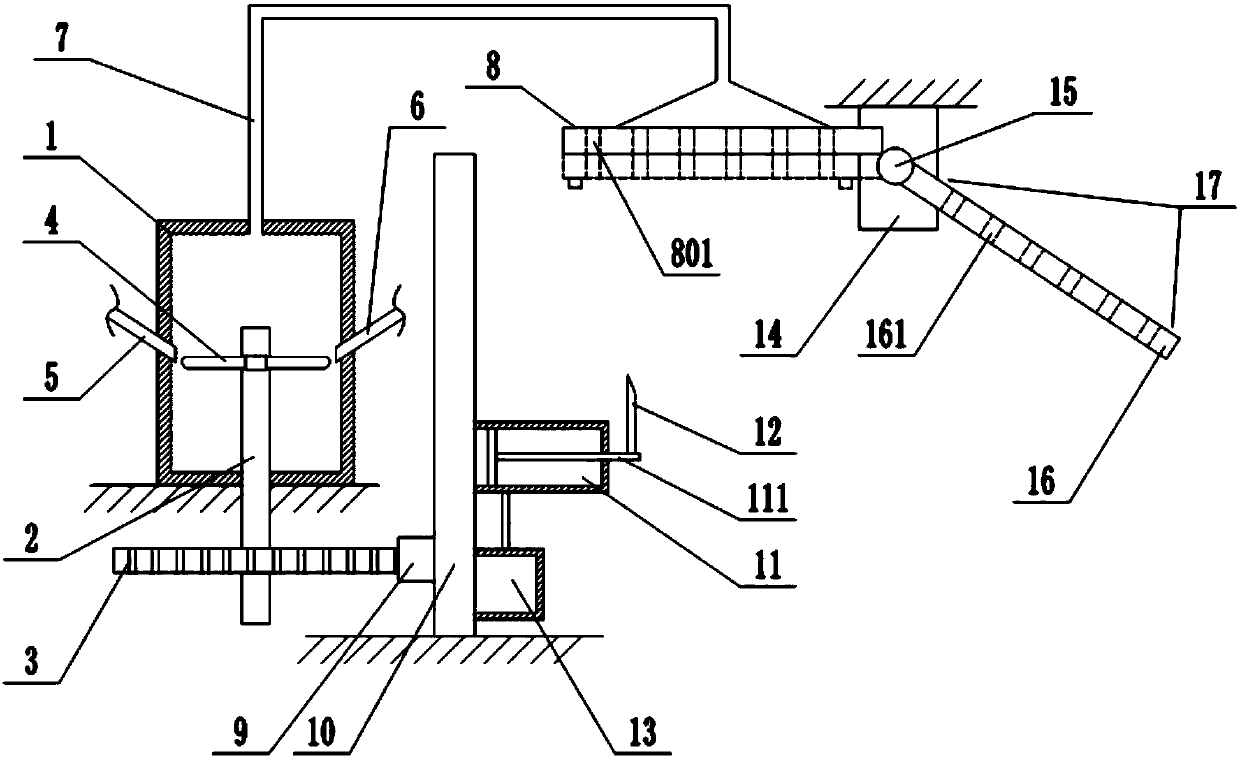

[0014] The reference signs in the drawings of the description include: cylinder 1, first rotating shaft 2, gear 3, rotating blade 4, first ventilation pipe 5, second ventilation pipe 6, air outlet pipe 7, first pressure plate 8, ventilation hole 801, rack 9, slide plate 10, telescopic cylinder 11, piston rod 111, cutter 12, lift cylinder 13, stepping motor 14, second rotating shaft 15, second pressing plate 16, air outlet 161, pressing unit 17.

[0015] This embodiment is basically as figure 1 As shown, the clothing cutting table includes a frame, and the frame is fixedly connected with a cylinder body 1 and a stepping motor 14. The cylinder body 1 is rotatably connected with a first rotating shaft 2, and the first rotating shaft 2 is set through the bottom wall of the cylinder body 1. A rotating shaft 2 is fixedly connected with a gear 3 and a plurality of rotating blades 4 , the rotating blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com