Composite structure bunchy yarn and production technology thereof

A technology of composite structure and production process, applied in the field of textile production, can solve the problems of difficult spinning, itchy skin, high fiber rigidity, etc., and achieve the effect of good appearance, good heat transfer performance, and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

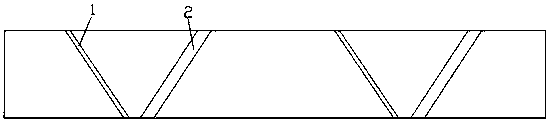

[0025] A composite structure slub yarn, including A slub yarn and B slub yarn, B slub yarn is wound on the surface of A slub yarn, and a composite structure slub yarn, A slub yarn and B The mass ratio of winding yarn is: 30-60%: 70-40%; A slub yarn is made by blending flax fiber and ultra-high molecular weight polyethylene fiber, and the blending ratio of flax fiber and ultra-high molecular weight polyethylene fiber is 20-80% : 80-20%, B winding yarn is made of spun silk and modal fiber blended, the blending ratio of spun silk and modal fiber is 20-80%: 80-20%, the modal fiber specification is 1.0dtex*38mm.

[0026] A production process of composite structure slub yarn, after pretreatment of flax, pretreatment of ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com