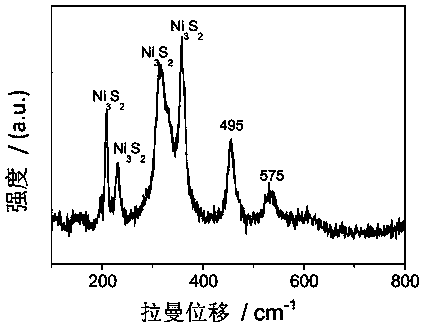

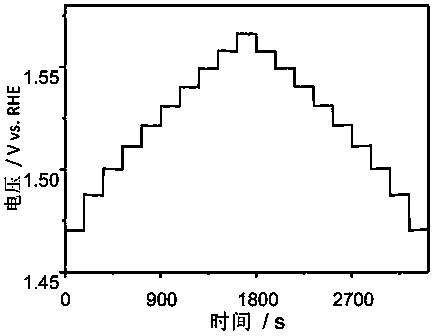

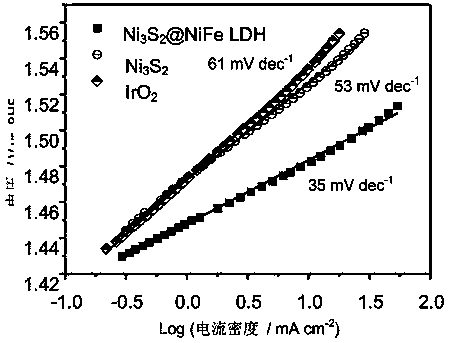

a ni 3 the s 2 @ni-fe LDH oxygen evolution electrocatalytic electrode and its preparation method and application

An electrocatalysis and electrode technology, which is applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of low binding force between nickel-based catalysts and substrates, unfavorable exposure of catalytic active sites, and influence on the efficiency of electrolysis of water, etc., to avoid catalysis Effects of decreased activity, good binding force and conductivity, excellent electrochemical stability and mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Pretreatment of the substrate: Cut the pure nickel sheet into a rectangle of 3.5cm·0.5cm, 1cm of the upper half as the clamping part, and 2.5cm of the lower half as the actual use part, immersed in the electrolyte for anodic oxidation deal with. Put the trimmed substrate into acetone for 20 minutes of ultrasonic vibration, then put it into absolute ethanol for 20 minutes of ultrasonic vibration, and then clean it with deionized water.

[0049] (2) Anodization of the substrate: an anodizing electrolyte is prepared with deionized water as a solvent, and the electrolyte composition is 1wt% ammonium fluoride, 80wt% phosphoric acid, and the rest is deionized water. The actual use part of the pretreated substrate in step (1) is immersed in the electrolyte, and the clamping part is connected to the anode electrode. The anodic oxidation device was SP‐150 electrochemical workstation, using a three-electrode system, the substrate was used as the working electrode, the platin...

Embodiment 2

[0098] (1) The pretreatment of the substrate is the same as step (1) in Example 1.

[0099] (2) The anodic oxidation of the substrate is the same as step (2) in Example 1, except that the electrolyte composition is 2wt% ammonium fluoride, 85wt% phosphoric acid, and the rest is deionized water.

[0100] (3) After the anodization is completed, the sample is removed, rinsed with deionized water and dried.

[0101] (4) The anodic oxidation sample is sulfided hydrothermally, and the hydrothermal solution is sulfided with deionized water. The solution components are 0.02mol / L sodium sulfide, 0.1mol / L ammonium fluoride, 5mol / L ethanol, and the rest are deionized Water, add the sample and the prepared solution into the hydrothermal reactor, the volume of the hydrothermal reactor is 25mL, add 10mL of the solution, and the volume ratio is 40%.

[0102] (5) The hydrothermal reactor is sealed and placed in a box-type resistance furnace for heating. The hydrothermal temperature is 140°C, ...

Embodiment 3

[0107] (1) The pretreatment of the substrate is the same as step (1) in Example 1.

[0108] (2) Anodization of the substrate: an anodizing electrolyte was prepared with deionized water as a solvent. The electrolyte composition was 0.5wt% ammonium fluoride, 75wt% phosphoric acid, and the rest was deionized water. The actual use part of the pretreated substrate in step (1) is immersed in the electrolyte, and the clamping part is connected to the anode electrode. The anodic oxidation device was SP‐150 electrochemical workstation, using a three-electrode system, the substrate was used as the working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. The voltage was increased from the open circuit potential to 5V at a rate of 10mV / s, and the voltage was maintained at 5V for 5 minutes, and the electrolyte temperature was 25°C.

[0109] (3) After the anodization is completed, the sample is remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com