A satellite flexographic printing machine for tipping paper printing and its printing process

A flexographic printing machine, flexographic printing technology, applied in the printing process, printing machine, letterpress printing, etc., can solve the problems of difficult tension control, poor printing accuracy, etc., achieve consistent tightness, improve return air efficiency, and prevent dryness The effect of edition phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

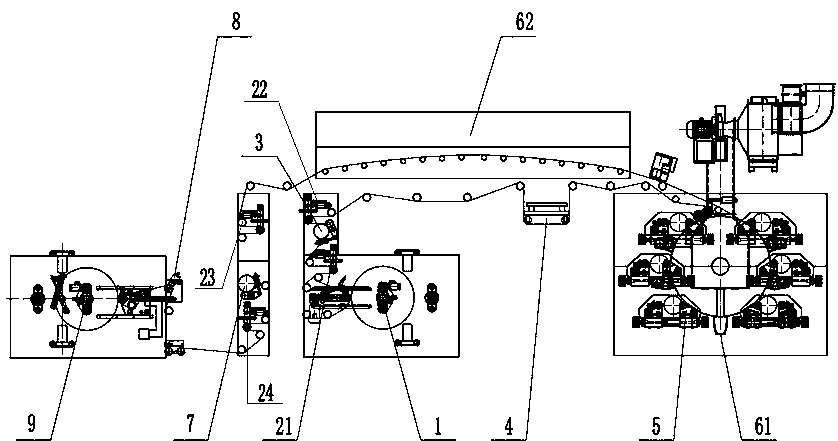

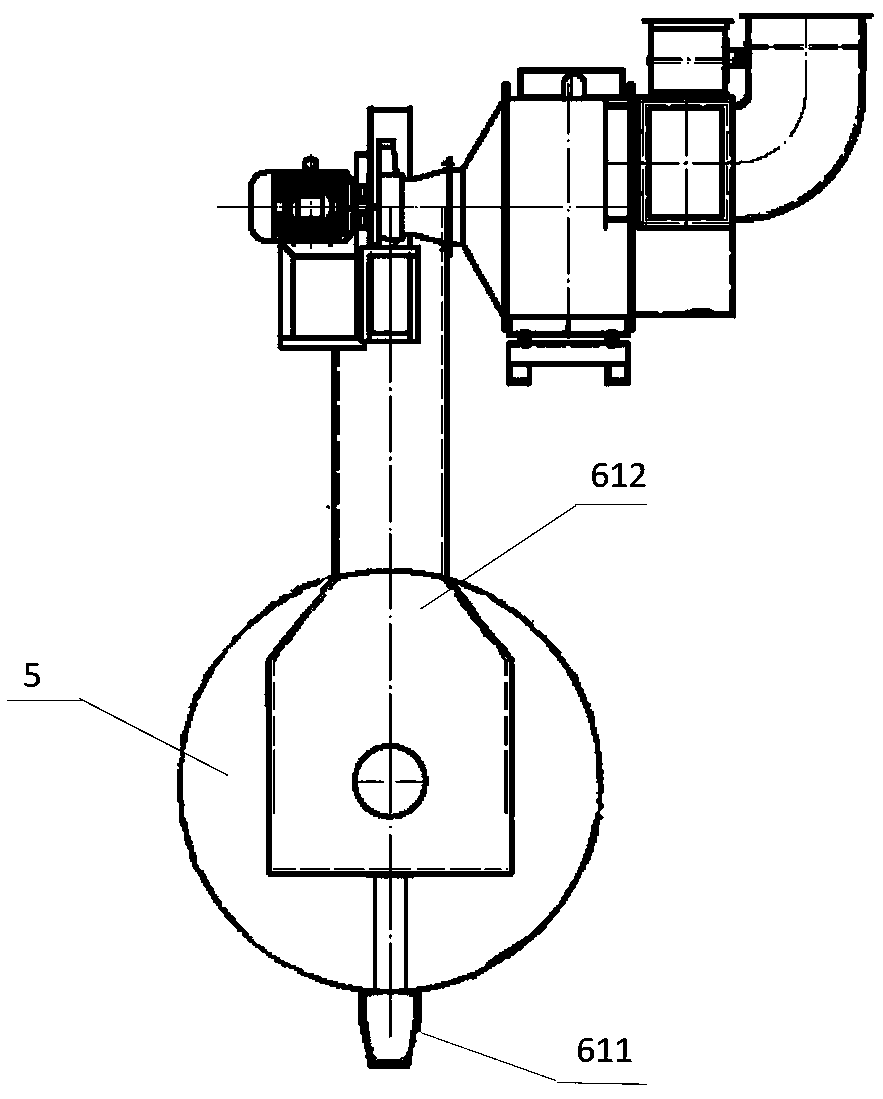

[0036] refer to figure 1 As shown, the present invention provides a satellite flexographic printing machine for tipping paper printing, including a feeding unit 1, a swing roller mechanism 2, a feeding traction unit 3, a deviation correction unit 4, and a satellite flexographic printing unit 5. Hot air drying unit 6, receiving water-cooled traction unit 7, slitting unit 8 and winding unit 9, each unit is set according to the technological requirements of tipping paper conveying, tension control, printing, drying, slitting and winding .

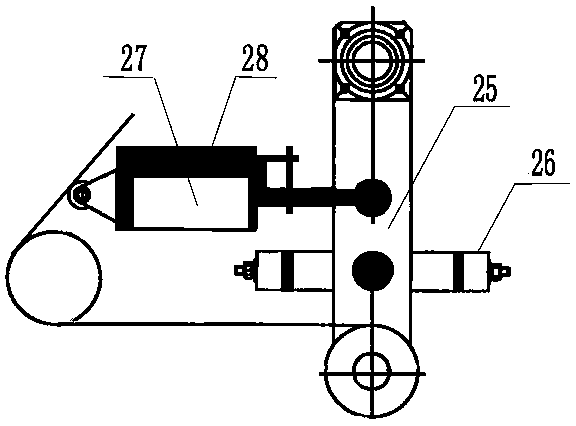

[0037] refer to figure 2 As shown, the swing mechanism 2 includes a first swing mechanism 21, a second swing mechanism 22, a third swing mechanism 23 and a fourth swing mechanism 24, and the first swing mechanism 21 is arranged on the discharge unit 1 Afterwards, the second pendulum roller mechanism 22 is arranged behind the said discharging traction unit 3, the third pendulum roller mechanism 23 is arranged behind the said main oven unit 6...

Embodiment 2

[0044] This embodiment provides a satellite flexographic printing process for tipping paper printing. Using the satellite flexographic printing machine in Embodiment 1 of the present invention, the transportation, tension control, printing, drying, and separation of tipping paper are completed. The cutting and winding process specifically includes the following steps:

[0045] Preparation before printing, adjust the feeding unit 1, swing roller mechanism 2, feeding traction unit 3, deviation correction unit 4, satellite flexo printing unit 5, hot air drying unit 6, receiving water cooling traction unit 7, cutting unit 8 and Rewinding unit 9.

[0046] (1) Install the tipping paper on the discharge unit 1, and complete the discharge of the tipping paper and the control of the discharge tension under the servo cooperation of the discharge unit 1 and the first swing roller mechanism 21. The specific process is as follows: : During the discharge process, the first pendulum roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com