Quick fix print head for ceramic printer

A printer and quick-solid technology, applied in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problems of high moisture, difficult to control the shape of the printed part, and the overall structure of the printed part deviates from the expected, to achieve the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

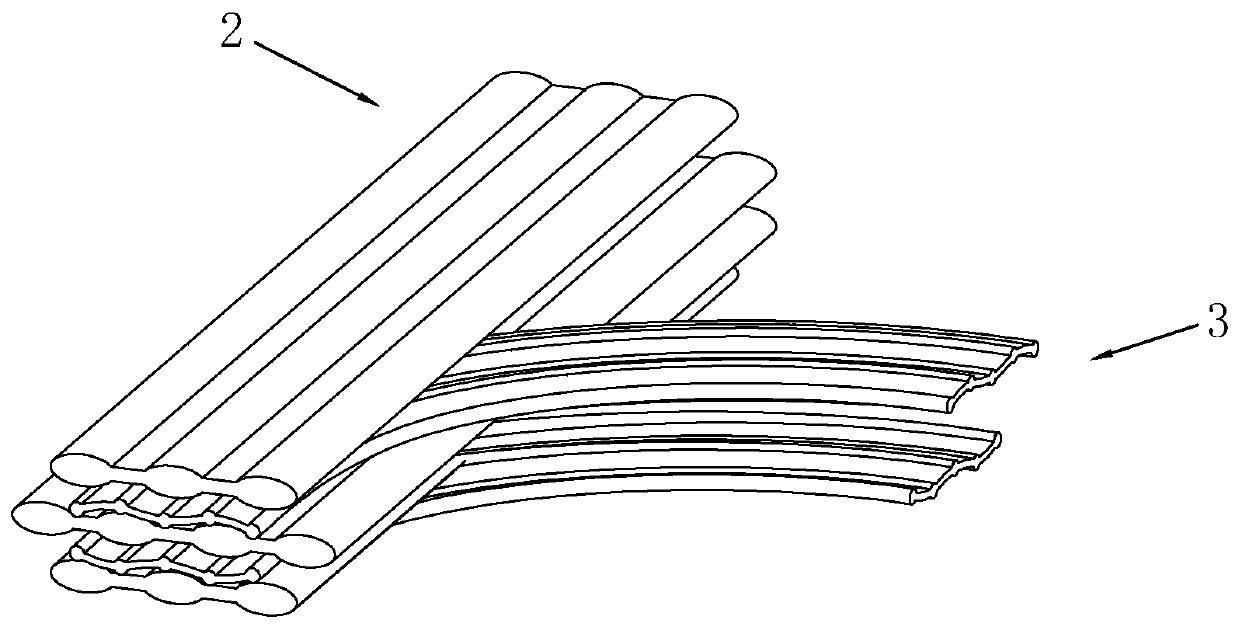

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

[0039] The present invention proposes a ceramic 3D printing solidification method, comprising the following steps:

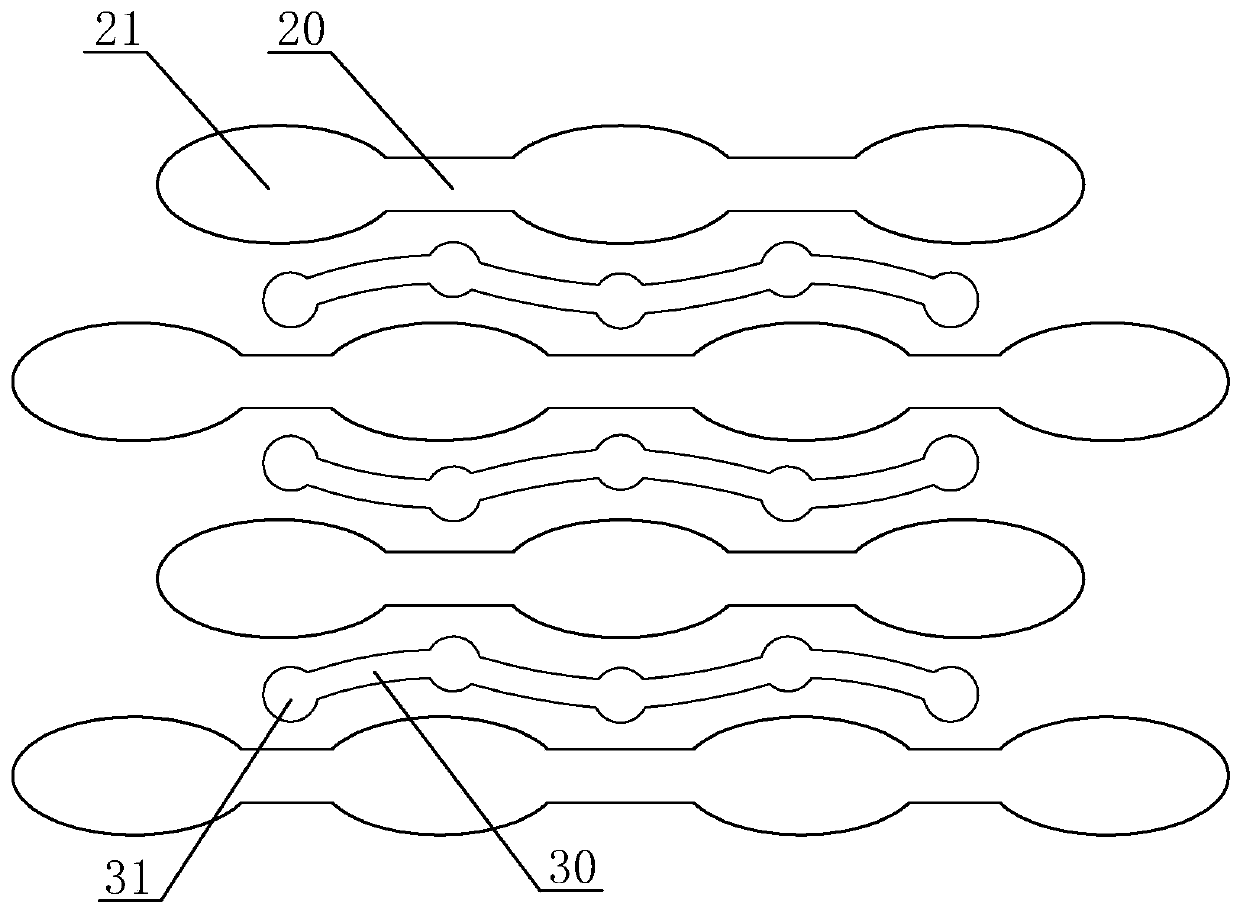

[0040] Step 1: Inject water into the mud, stir the mud to fully mix the water and the mud, and increase the fluidity of the mud;

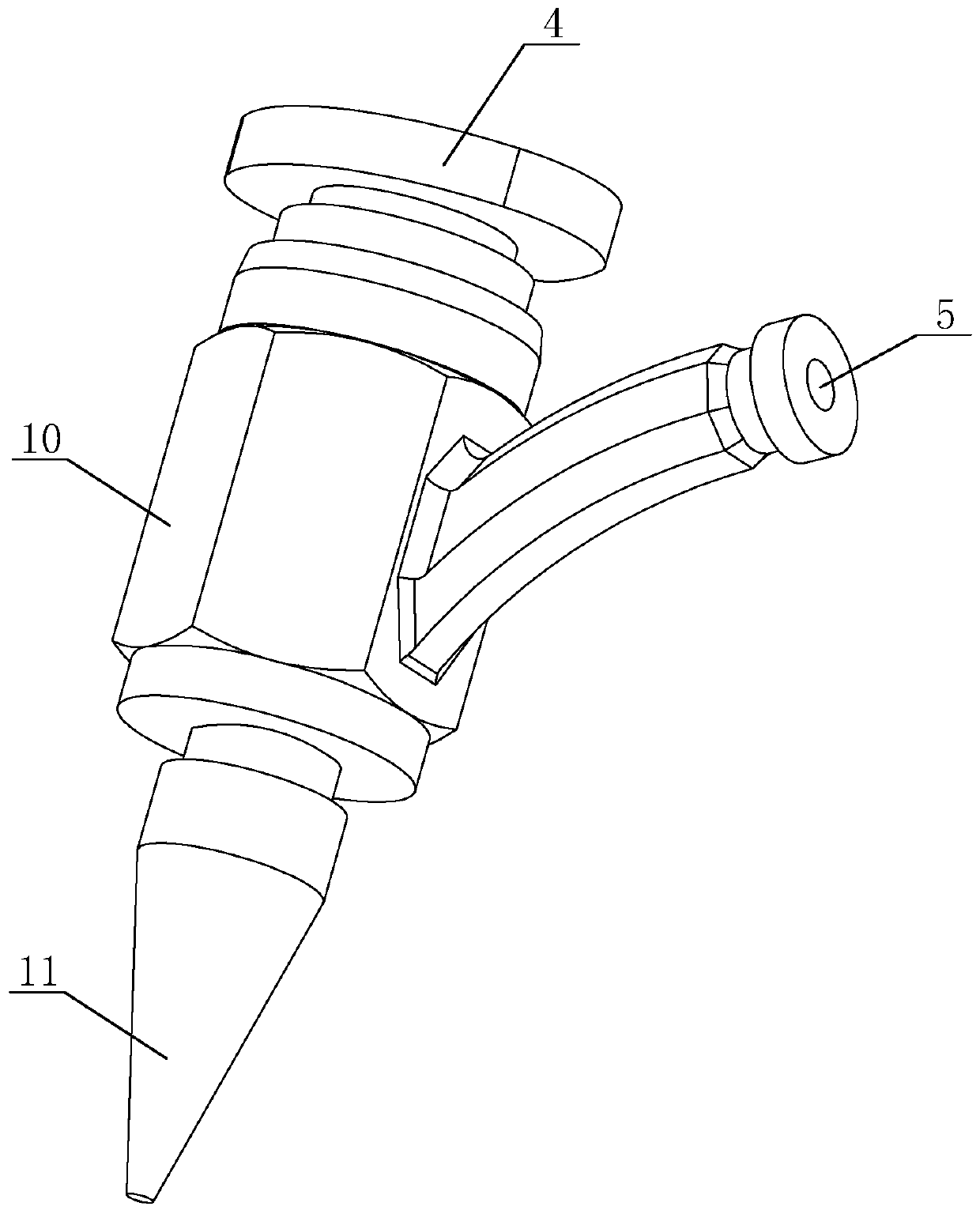

[0041] Step 2: Inject the mud into the nozzle through the pipe, and inject curing agent B (α-cyanoacrylate ethyl ester) into the nozzle at the same time, the curing agent B, water and mud are fully mixed in the nozzle, water and curing agent B reaction catalyzes curing agent B, which undergoes polyaddition reaction, rapidly solidifies and sticks the adherend firmly;

[0042] Step 4: After the mud is mixed, quickly extrude it from the nozzle to the bearing surface. After the polyaddition reaction continues for a period of time, the mud is completely solidified and has a certain hardness, and the structure of the printed part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com