Locating and guiding hand drill

A positioning-guided, hand-operated drilling technology, applied in portable drilling rigs, drilling/drilling equipment, metal processing, etc., can solve problems affecting parts assembly, tool breakage, long production cycle, etc., to ensure positional accuracy and dimensional accuracy , Guaranteed concentricity and improved processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

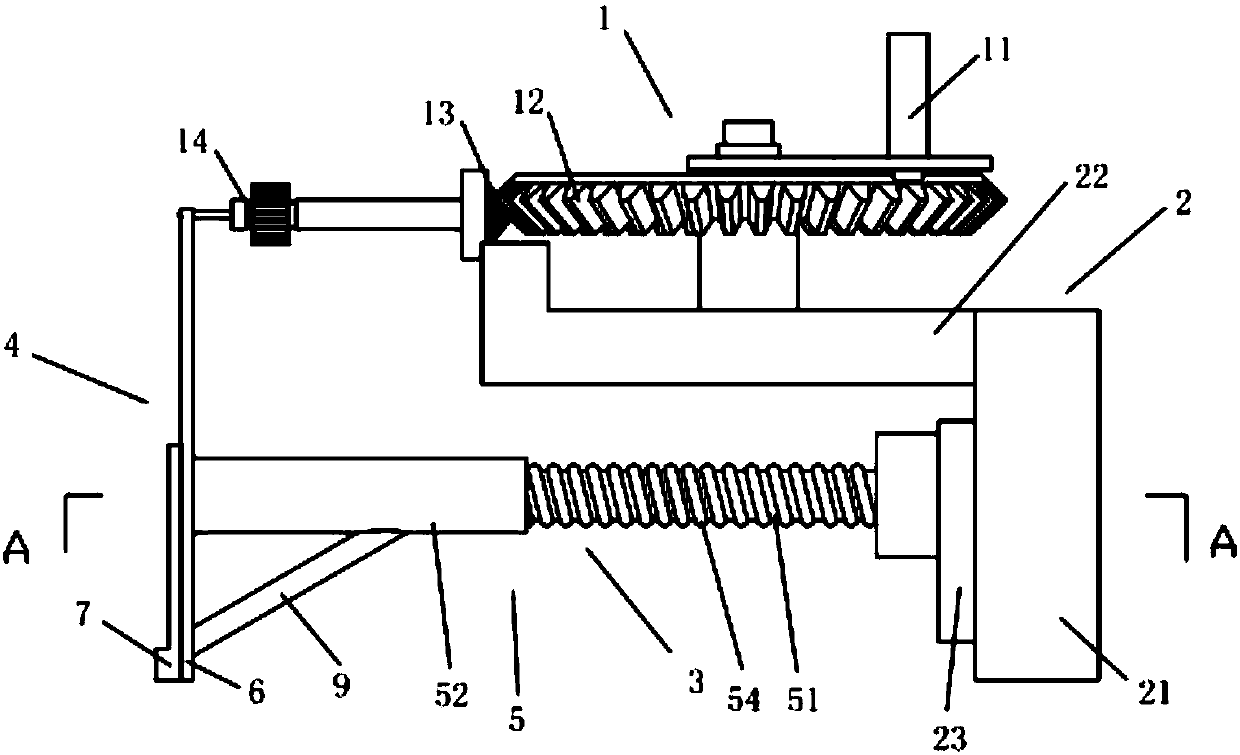

[0029] The present invention will be further described below in conjunction with accompanying drawing.

[0030] The existing hand drills in the market do not have a positioning device and a guide device, and the processed parts often have quality problems due to human factors, and the processed parts of the hand drill have high requirements on the skills of the operator and do not have versatility. Therefore, the present invention provides A fixed-guided hand drill that can be positioned as well as guided, such as figure 1 Shown, positioning guide hand drill of the present invention comprises:

[0031] Hand drill 1 and fixed frame 2, fixed frame 2 is used for hand drill 1 is fixed on the machine tool (not shown in the figure), hand drill 1 is fixedly installed on the upper end face of fixed frame 2, in addition, this The invention also includes a guiding device 3 capable of guiding and a positioning device 4 capable of positioning, wherein,

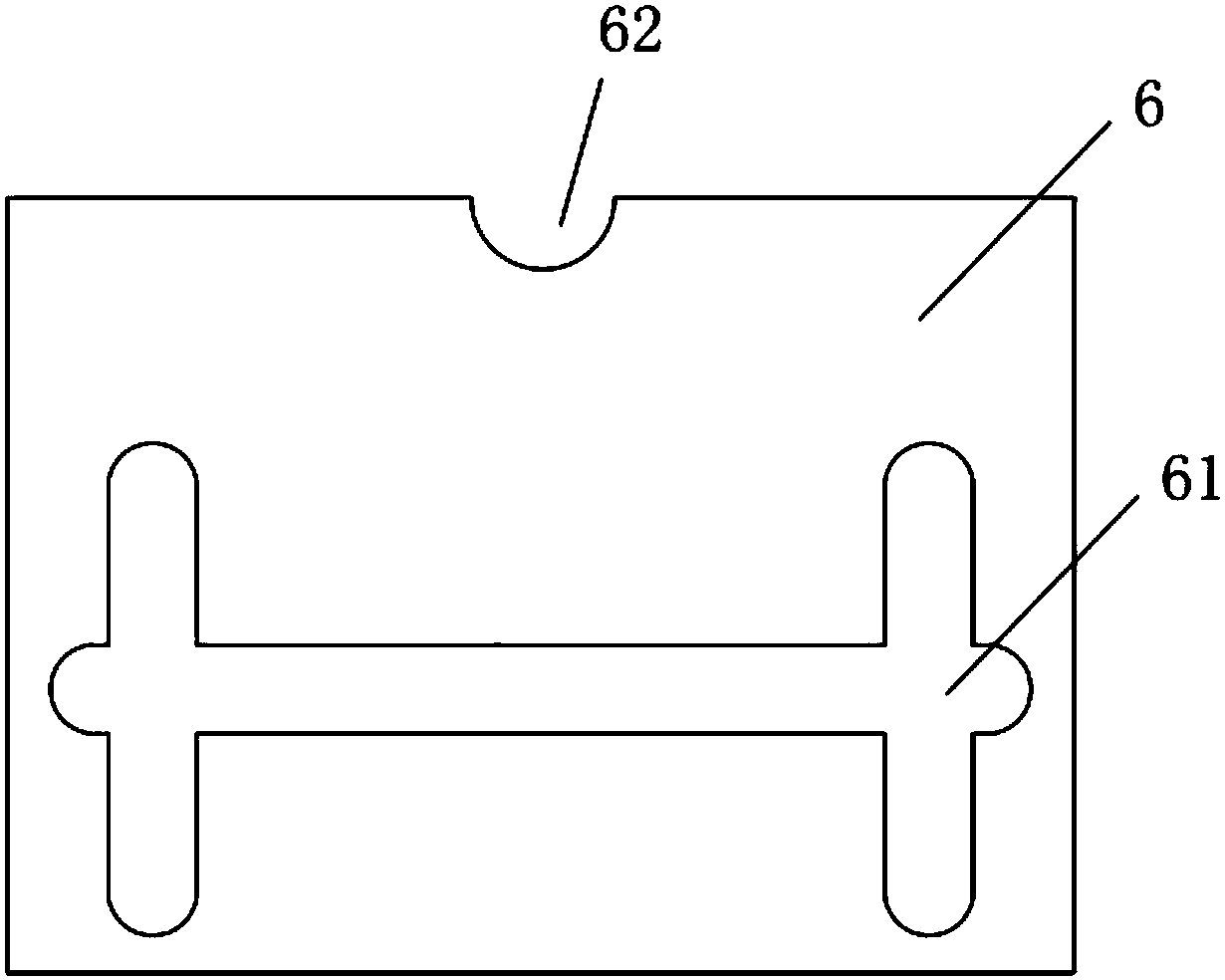

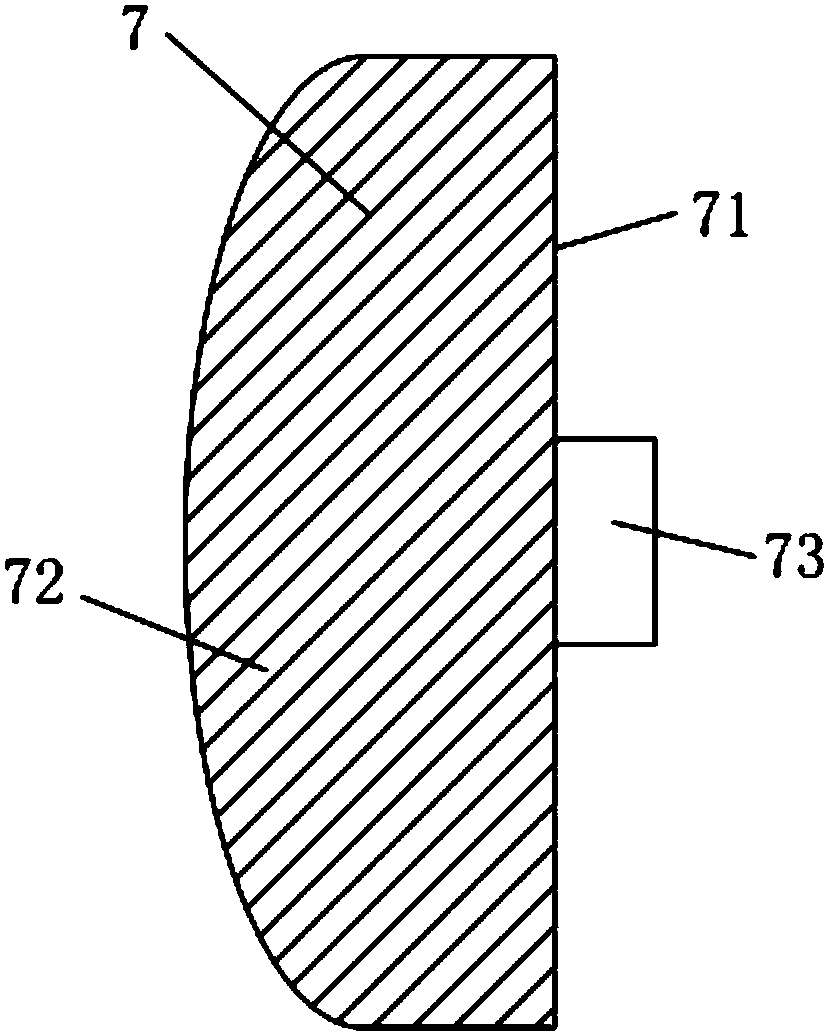

[0032] Guide device 3 comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com