A kind of aluminum ingot blank making process

An aluminum ingot and process technology, which is applied in the field of aluminum ingot processing technology for remelting, can solve the problems affecting hydrogen and the viscosity difference of aluminum liquid, and achieve the effect of slowing down the condensation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

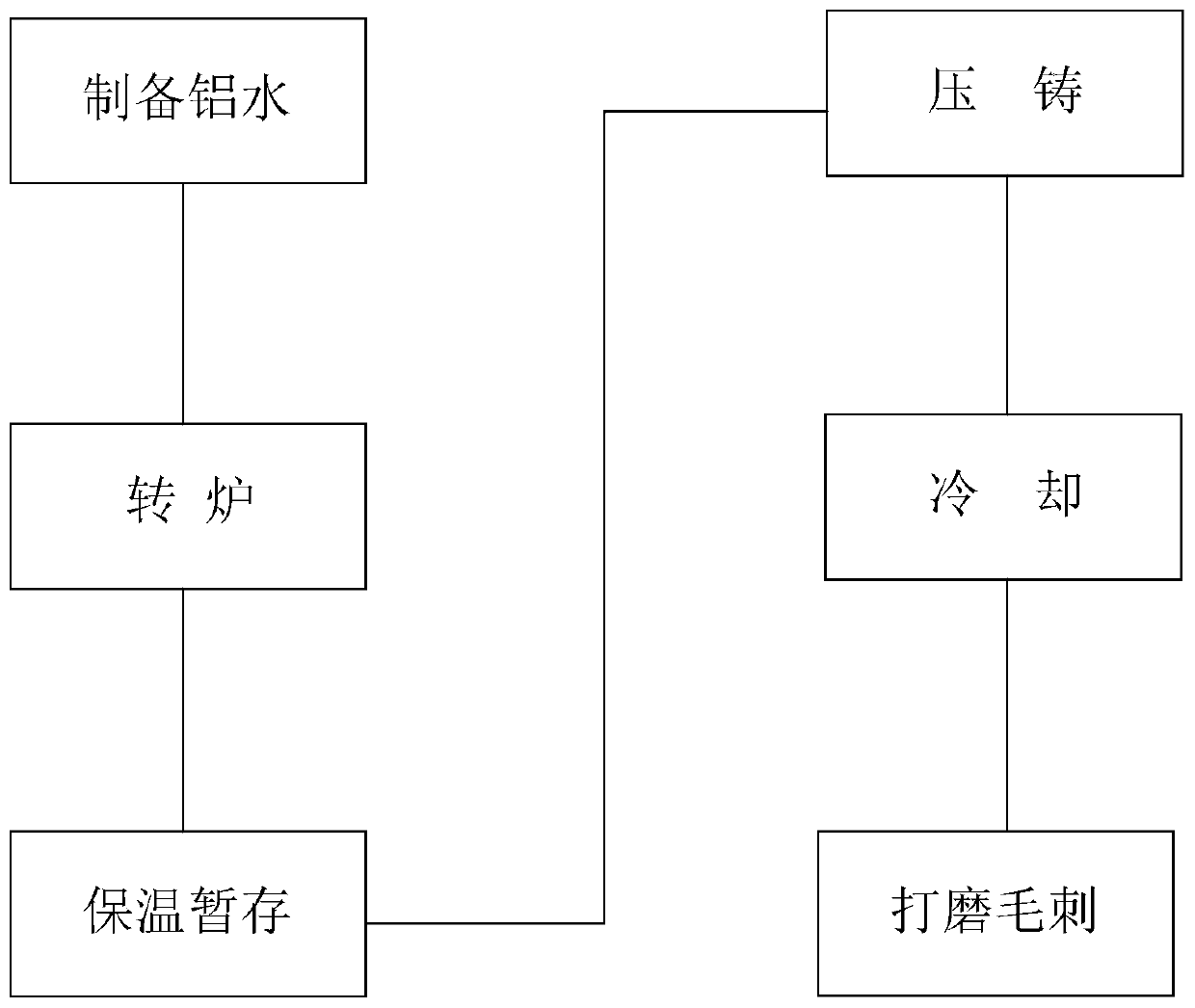

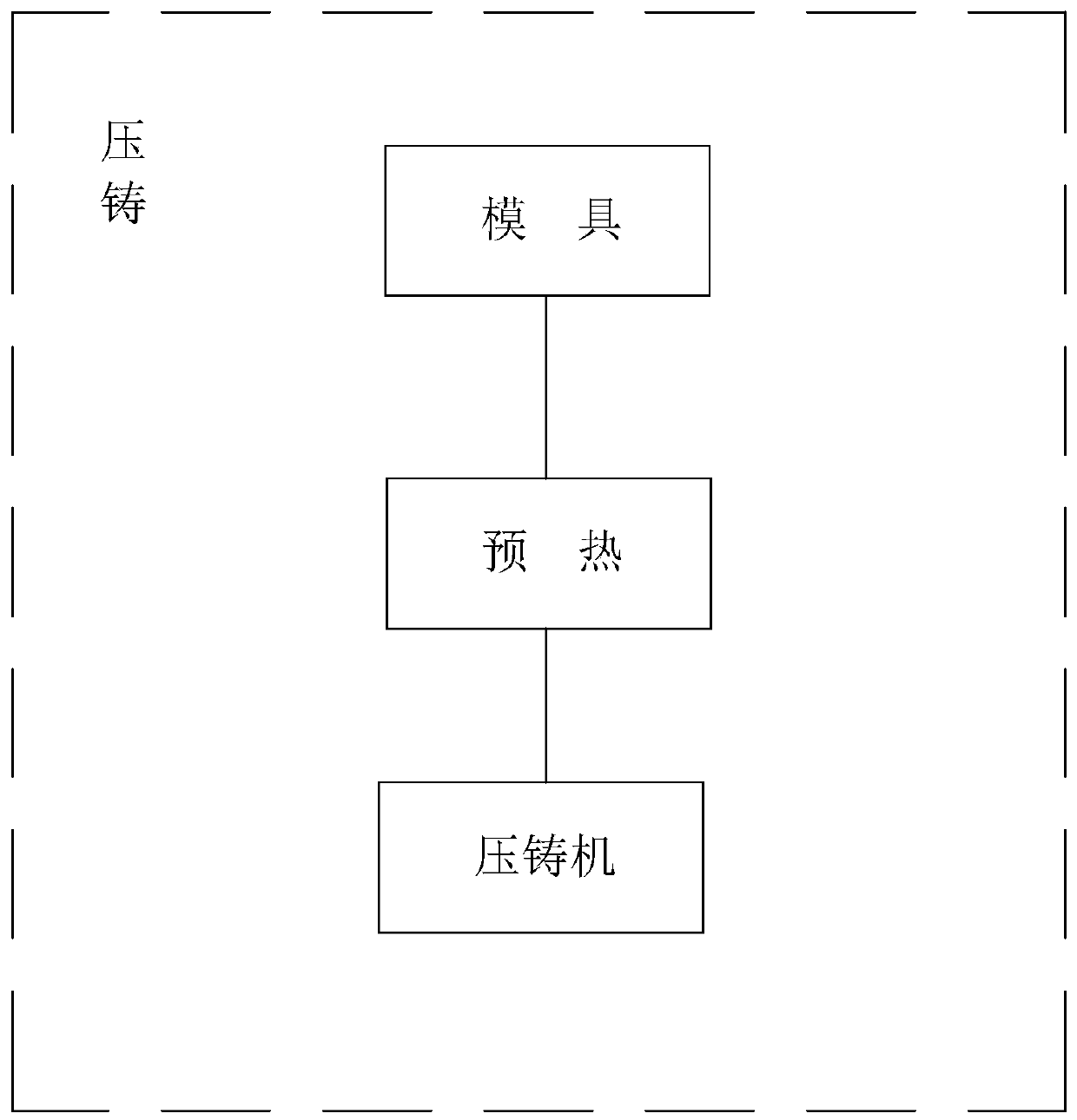

[0036] An aluminum ingot billet manufacturing process provided in this embodiment has a structure as shown in the figure.

[0037] The aluminum ingot blank making process includes:

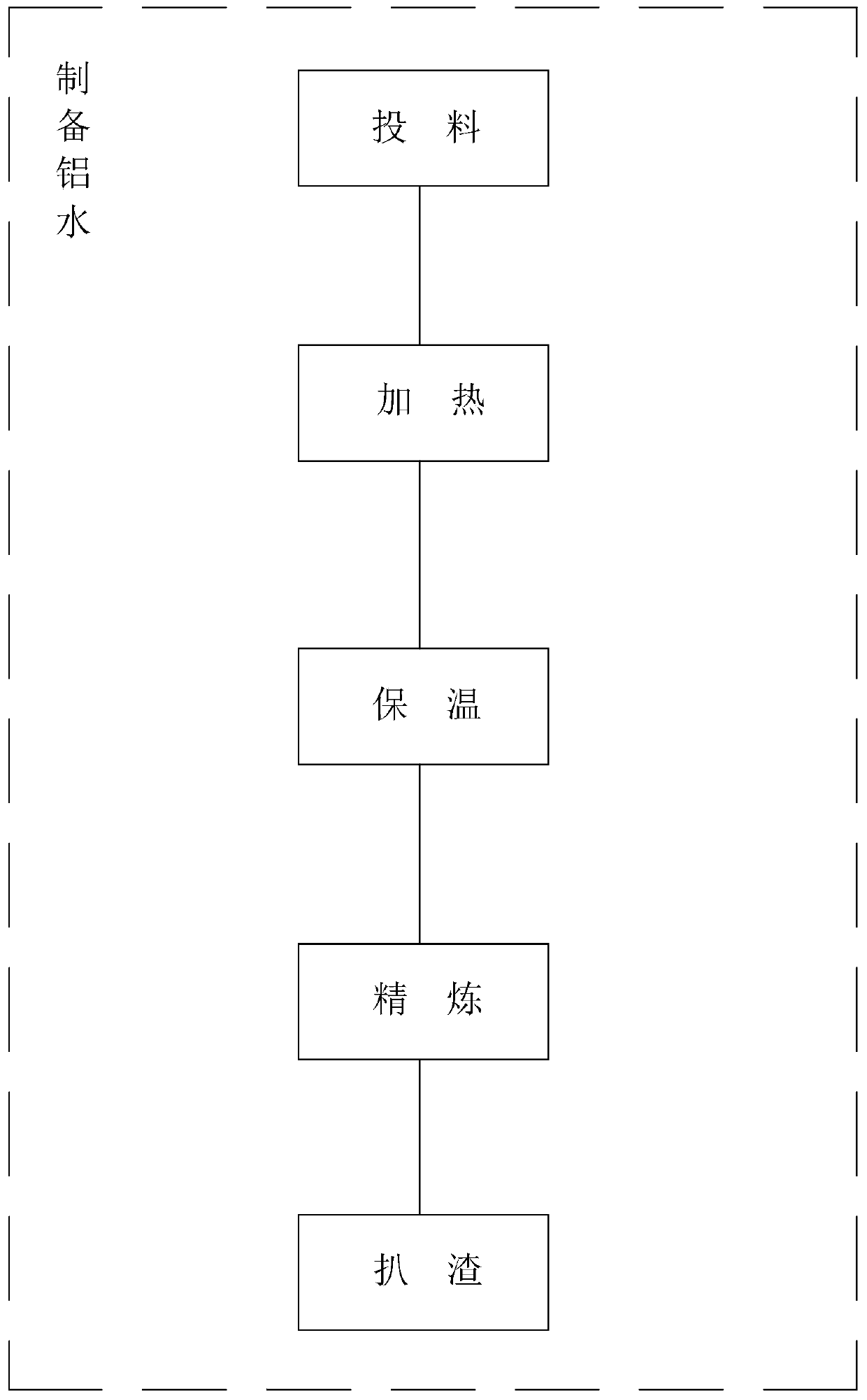

[0038] S1: Prepare molten aluminum, put the aluminum ingot into the aluminum melting furnace and heat until it turns into molten aluminum. The process is:

[0039] Feeding, put the aluminum ingots in piles and place them in the aluminum melting furnace. The aluminum ingots are stacked layer by layer, and the aluminum ingots on two adjacent layers are arranged crosswise along the length direction. The aluminum ingots on the same layer are parallel to each other, and The distance between two adjacent aluminum ingots on the same layer is not less than one-fifth of the width of the aluminum ingots, and the aluminum ingots are stacked into a boss shape, that is, the geometric area formed by each layer of aluminum ingots becomes smaller along with the height of the aluminum stack;

[0040] Heating, tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com