High-pressure water jet cleaning automatic line of wide-opening barrel-shaped containers

A high-pressure water jet, wide-mouth technology, applied in the field of automatic lines, can solve the problems of light labor, low efficiency, and harsh working environment conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

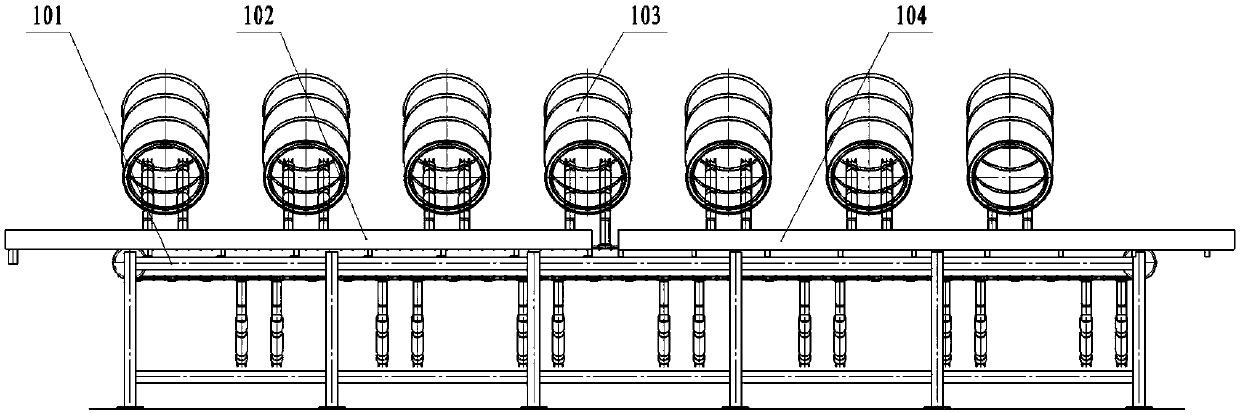

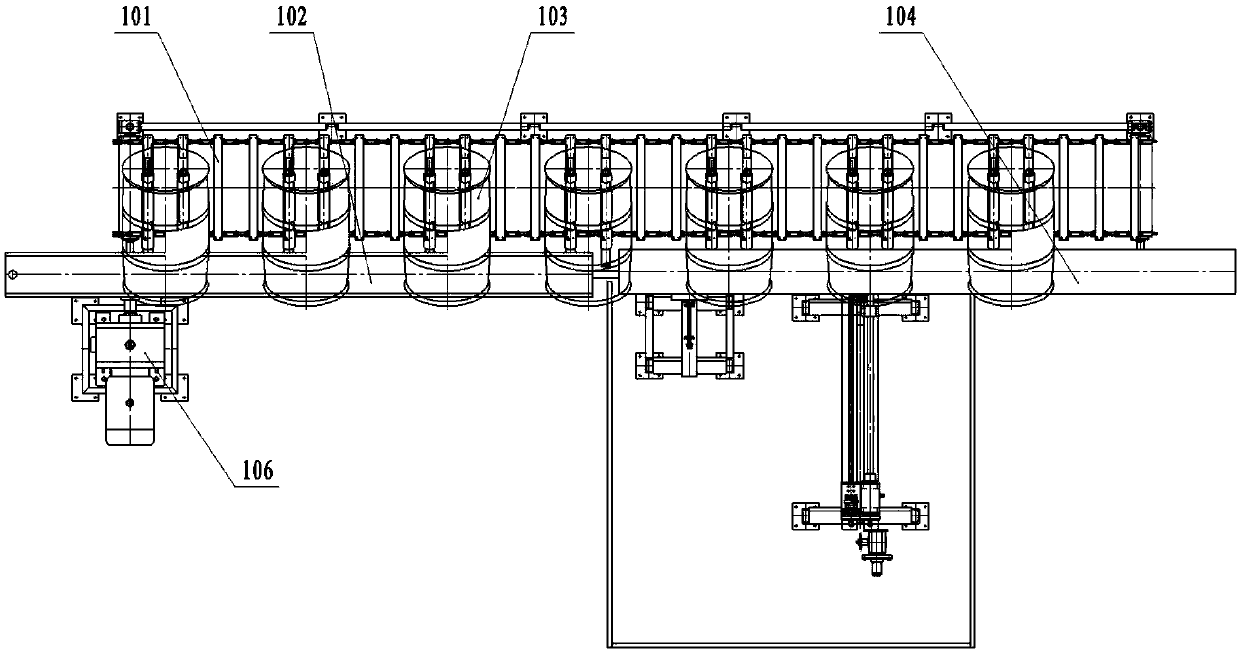

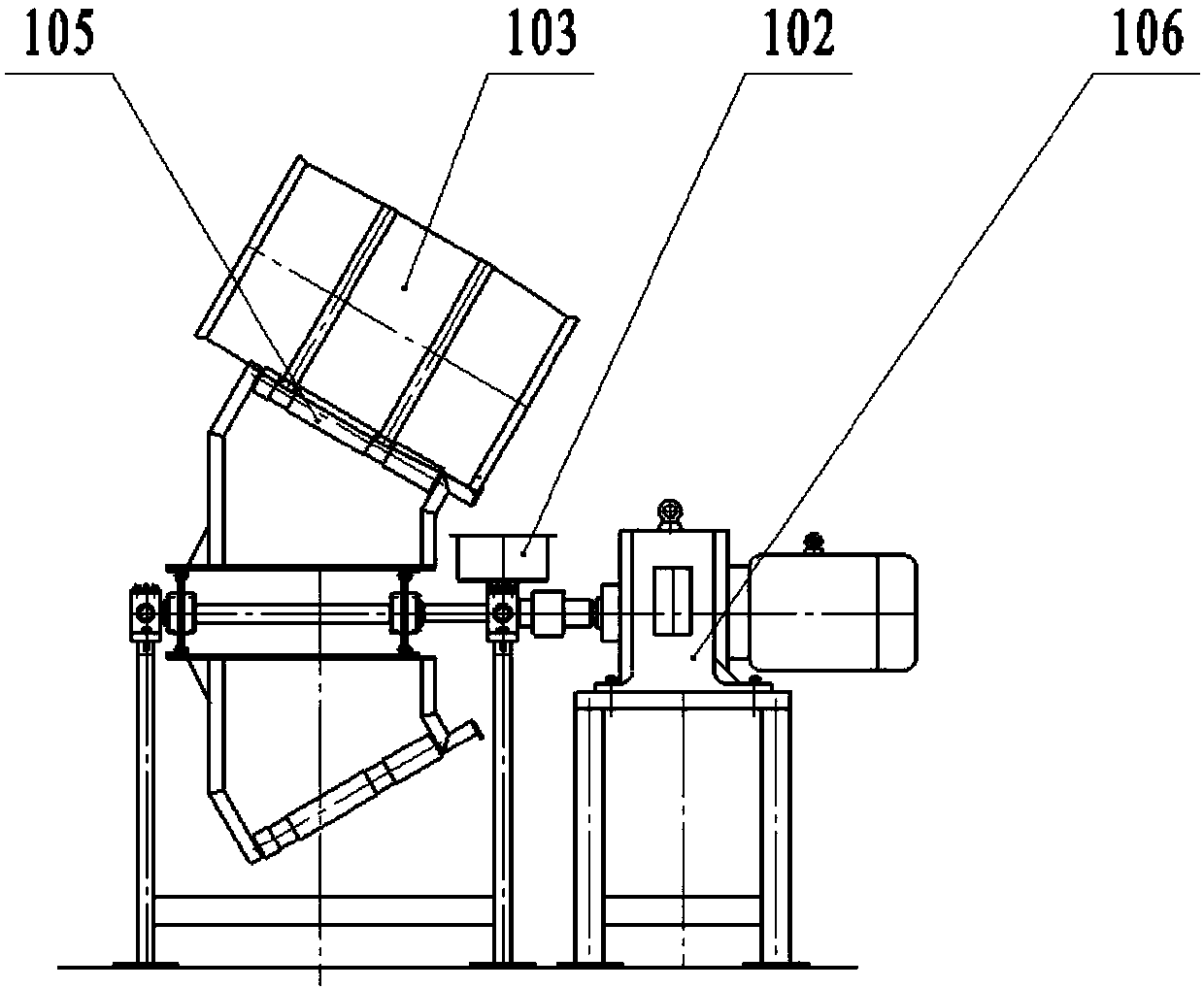

[0027] Such as Figure 1a , Figure 1b , Figure 1c , figure 2 and image 3 As shown, the present invention includes a conveying line, a mouth and outer wall cleaning mechanism and an inner wall cleaning mechanism.

[0028] The main body 101 of the conveying line is a stainless steel chain-plate conveyor, which is driven by the driving device 106 and operates intermittently under the joint action of the control system, sensors and positioning stops, and obtains more accurate positioning when it stops. An inclined idler frame 105 with a baffle at the end for supporting the cleaning object—a wide-mouthed container barrel 103 is installed on it; on the lower side of the idler frame 105, the front half is provided for recycling the residue in the barrel. The material recovery tank 102 of the material is provided with a waste residue conveyor 104 for removing the waste residue in the barrel cleaned from the second half of the barrel mouth cleaning station. The waste residue co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com