Alginate wound surface restoring dressing and preparation method thereof

A technology of wound repair and alginate, which is applied in the fields of alginate rayon, pharmaceutical formula, rayon manufacturing, etc. It can solve the problems of accelerating wound healing, reduce the number of dressing changes and improve comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

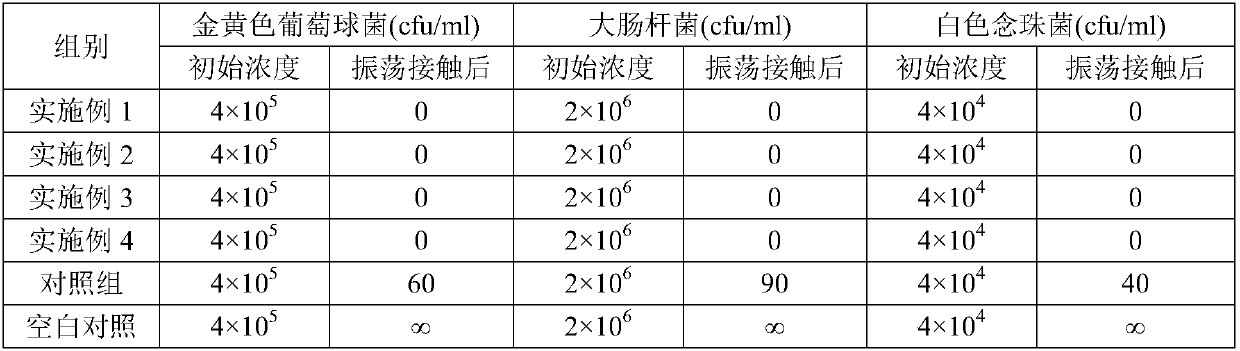

Examples

Embodiment 1

[0027] The alginate wound repair dressing adopts the following preparation process:

[0028] (1) Add the bioactive powder into the mixture of water and ethanol (volume ratio 1:1), and disperse the powder evenly to form a suspension;

[0029] (2) Immerse hydrophobically modified calcium alginate fibers in saturated KMnO 4 6min, and then washed with distilled water to obtain coarse alginate fiber;

[0030] (3) Immerse the above-mentioned coarse alginate fiber into the suspension and fully soak it, and spray the suspension evenly on the surface of the fiber, then centrifuge and dehydrate, soak the obtained wet fiber in the ethanol solution, centrifuge to remove the ethanol, and naturally Drying in the air, followed by vacuum drying at 60°C, the weight percent content of the finally obtained bioactive powder in the dressing is 10%;

[0031] (4) The fibers processed in the above 3) are cut into short fibers, and then made into non-woven fabrics through carding, net laying, and ac...

Embodiment 2

[0035] The alginate wound repair dressing adopts the following preparation process:

[0036] (1) Add the bioactive powder into the mixture of water and ethanol (volume ratio 1:1), and disperse the powder evenly to form a suspension;

[0037] (2) Immerse hydrophobically modified calcium alginate fibers in saturated KMnO 4 5min, and then washed with distilled water to obtain coarse alginate fiber;

[0038] (3) Immerse the above-mentioned coarse alginate fiber into the suspension and fully soak it, and spray the suspension evenly on the surface of the fiber, then centrifuge and dehydrate, soak the obtained wet fiber in the ethanol solution, centrifuge to remove the ethanol, and naturally Drying in the air, followed by vacuum drying at 80°C, the weight percent content of the finally obtained bioactive powder in the dressing is 15%;

[0039] (4) The fibers processed in the above 3) are cut into short fibers, and then made into non-woven fabrics through carding, net laying, and ac...

Embodiment 3

[0043] The alginate wound repair dressing adopts the following preparation process:

[0044] (1) Add the bioactive powder into the mixture of water and ethanol (volume ratio 1:1), and disperse the powder evenly to form a suspension;

[0045] (2) Immerse hydrophobically modified calcium alginate fibers in saturated KMnO 4 8min, and then washed with distilled water to obtain coarse alginate fiber;

[0046] (3) Immerse the above-mentioned coarse alginate fiber into the suspension and fully soak it, and spray the suspension evenly on the surface of the fiber, then centrifuge and dehydrate, soak the obtained wet fiber in the ethanol solution, centrifuge to remove the ethanol, and naturally Drying in the air, followed by vacuum drying at 70°C, the weight percent content of the finally obtained bioactive powder in the dressing is 5%;

[0047] (4) The fibers processed in the above 3) are cut into short fibers, and then made into non-woven fabrics through carding, net laying, and acu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com