Fixing protection mechanism for continuous adjustment of pressure on cylindrical lithium battery

A fixed protection and lithium battery technology, which is applied in the testing of machines/structural components, measuring devices, vibration testing, etc., can solve problems such as failure to achieve a fixed effect, damage to test samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

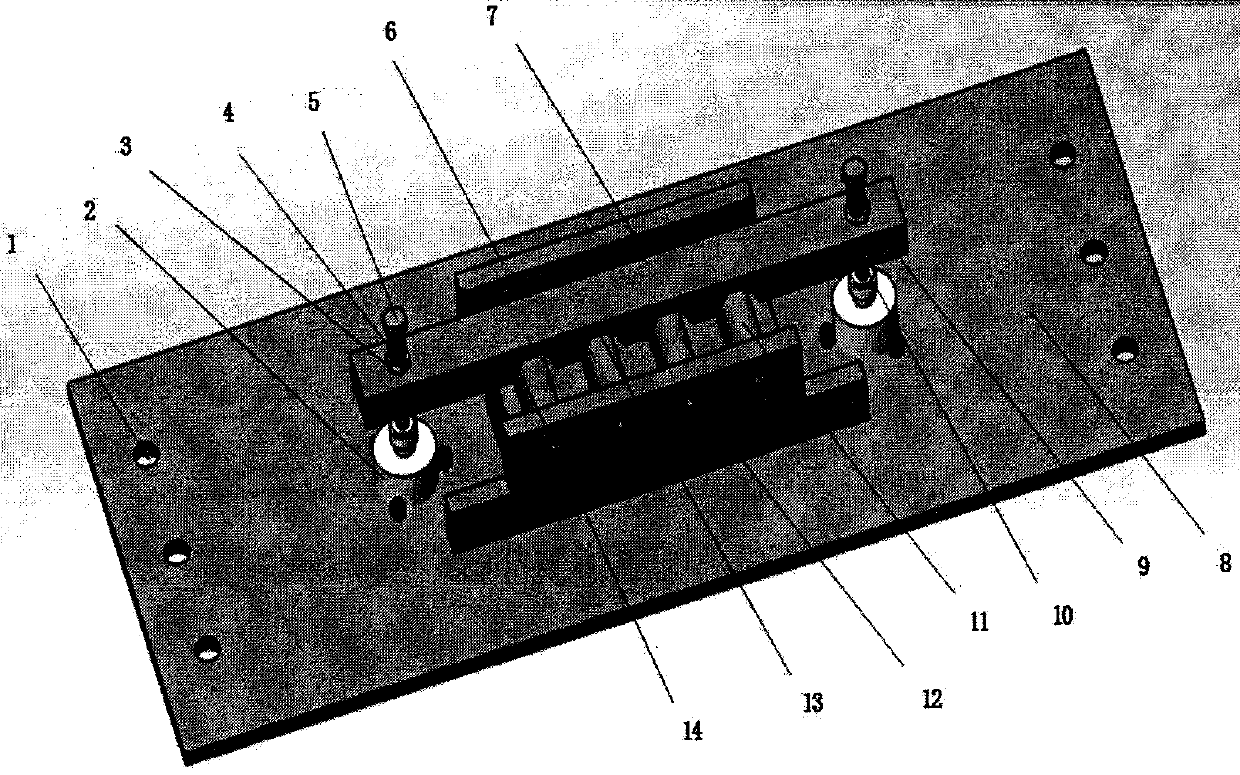

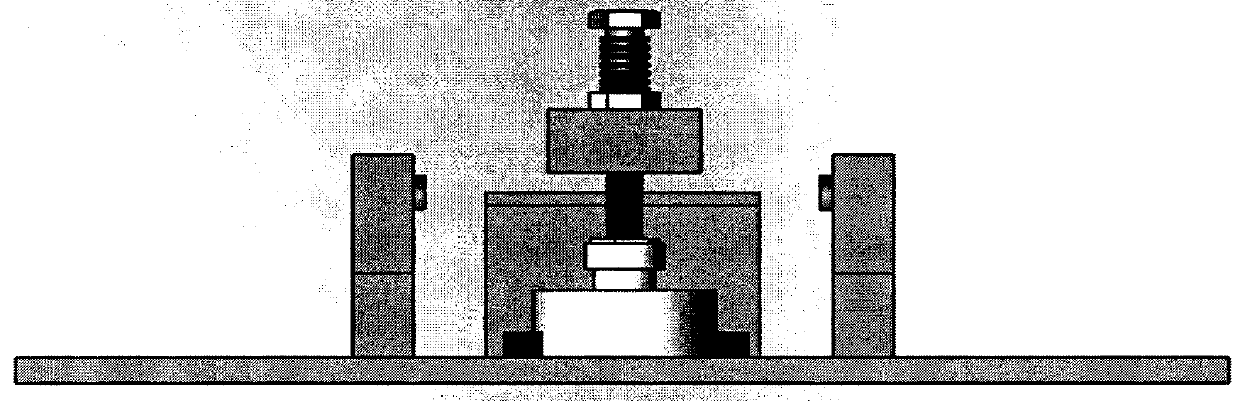

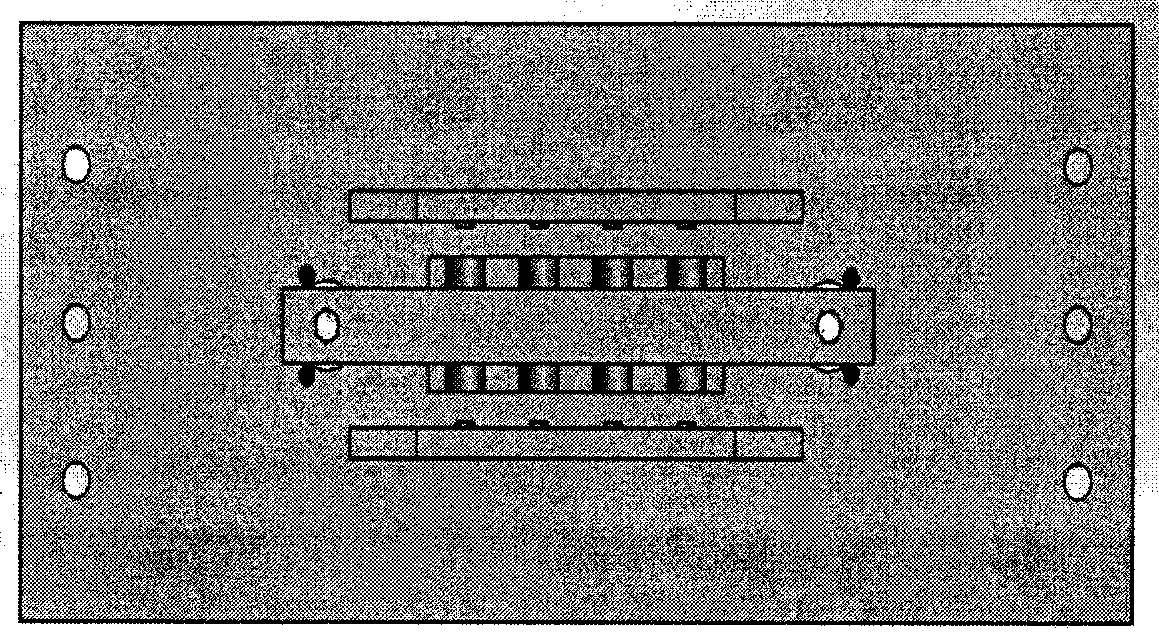

[0021] The detailed working method of this patent will be described below through specific embodiments and accompanying drawings.

[0022] like figure 1 As shown, because the present embodiment is a symmetrical structure, so for the bottom plate fixing hole 1, stepper motor 2, nut 3, spring 4, screw rod 5, fixed electrode 7, movable nut 10, and movable electrode 12 in the figure all refer to Substitute both side components.

[0023] like figure 1 As shown, the fixed electrode electrode 7 is installed on the horizontal pressing plate 6, and the position of this electrode is fixed and cannot move back and forth in the horizontal direction.

[0024] like figure 1 As shown, the fixed electrode 7 is located at the same height as the horizontal platen 6 and the placed cylindrical lithium battery electrode.

[0025] like figure 1 As shown, the horizontal pressing plate on the other side of the horizontal pressing plate 6 is made of the same material as the horizontal pressing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com