A kind of preparation method of ultra-large porous silicate molecular sieve

A pore silicate, molecular sieve technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of cumbersome steps and limited application of molecular sieves, and achieve good thermal stability.

Active Publication Date: 2019-10-01

NANJING UNIV

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the synthesis of this molecular sieve requires the use of a very expensive substituted cobaltocene as a template. When the molecular sieve is roasted, the template is transformed into CoO. It needs to be washed with acid to remove CoO to obtain a pure molecular sieve. The steps are cumbersome, which severely limits the application of the obtained molecular sieve.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

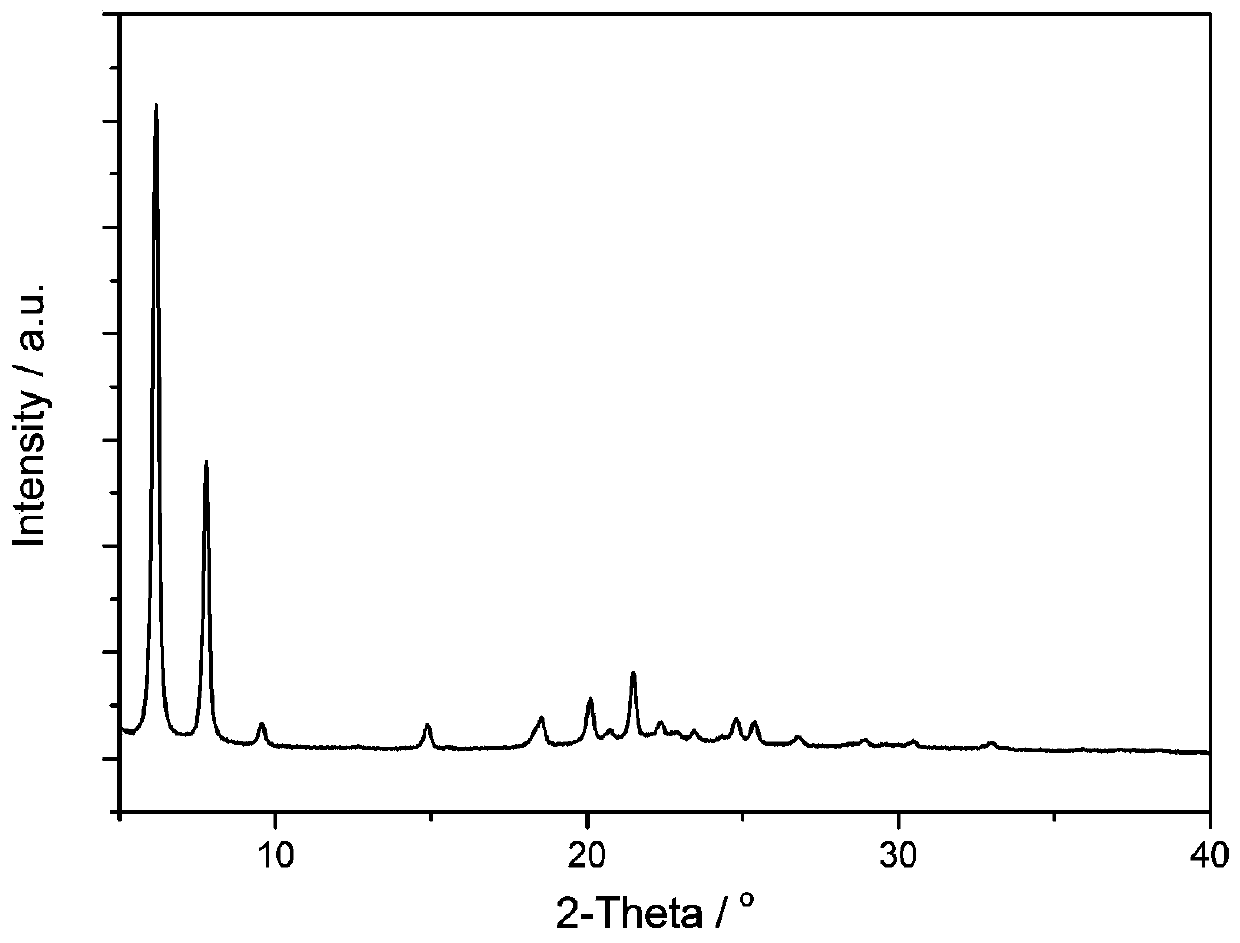

The invention discloses a preparation method for a super-macroporous silicate molecular sieve material. The molecular sieve material is obtained by utilizing a low-cost template agent and adopting a hydrothermal synthesis method. The prepared super-macroporous silicate molecular sieve has a UTD-1 structure, 14-ring pore channels in the direction of a crystal axis c and good thermal stability, canbe doped with heteroatoms, and has potential application value in the fields of petrochemistry, fine chemical engineering, life sciences and the like.

Description

technical field The invention belongs to the field of crystalline microporous materials, and in particular relates to a preparation method of an ultra-large microporous silicate molecular sieve material. Background technique Molecular sieve materials are a class of TO 4 (T represents the oxidation state atom with +4 valence or +3 valence usually, such as Si, P, Al, B, Ge, Ga, etc.) A type of inorganic microporous solid material composed of tetrahedra sharing vertices. Generally, the composition of molecular sieves can be represented by the following empirical chemical formula: p(M 1 / n XO 2 )·qYO 2 ·rR·wH 2 O, where M represents one or more +n-valent organic or inorganic cations; X represents one or more trivalent elements; Y represents one or more tetravalent elements, usually Si; R represents one or more an organic molecule. For a molecular sieve with a specific structure obtained by a specific synthesis method, whether it is a freshly synthesized product or a sample ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B39/48

Inventor 杜红宾陈飞剑高子豪刘代融訾文文

Owner NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com