MIM full-automatic component placement equipment

A fully automatic and decoration technology, applied in the field of MIM automatic decoration equipment, can solve the problems of unstable operation quality, large demand for personnel, cumbersome work process, etc., and achieve the goal of reducing labor input, ensuring operation quality and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

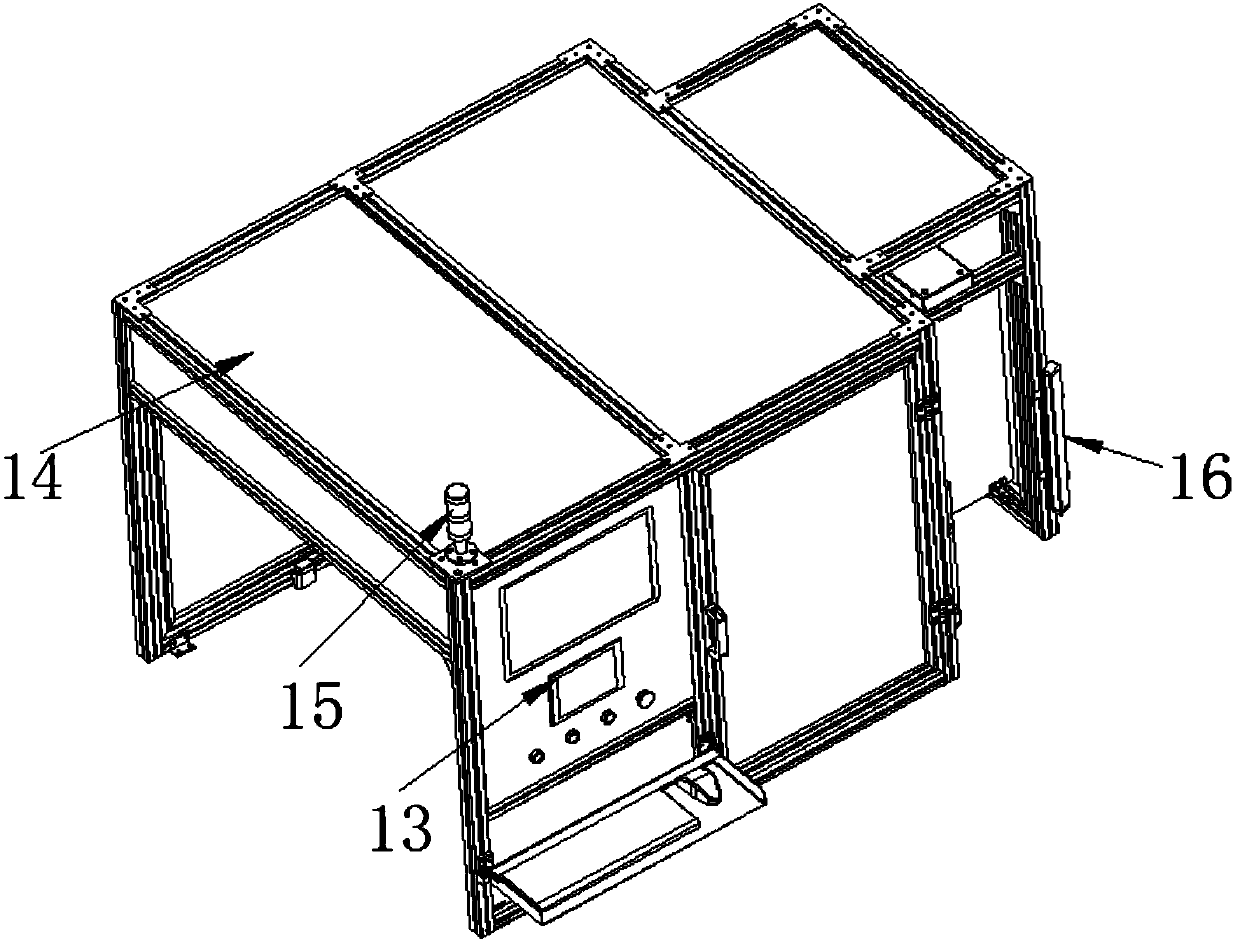

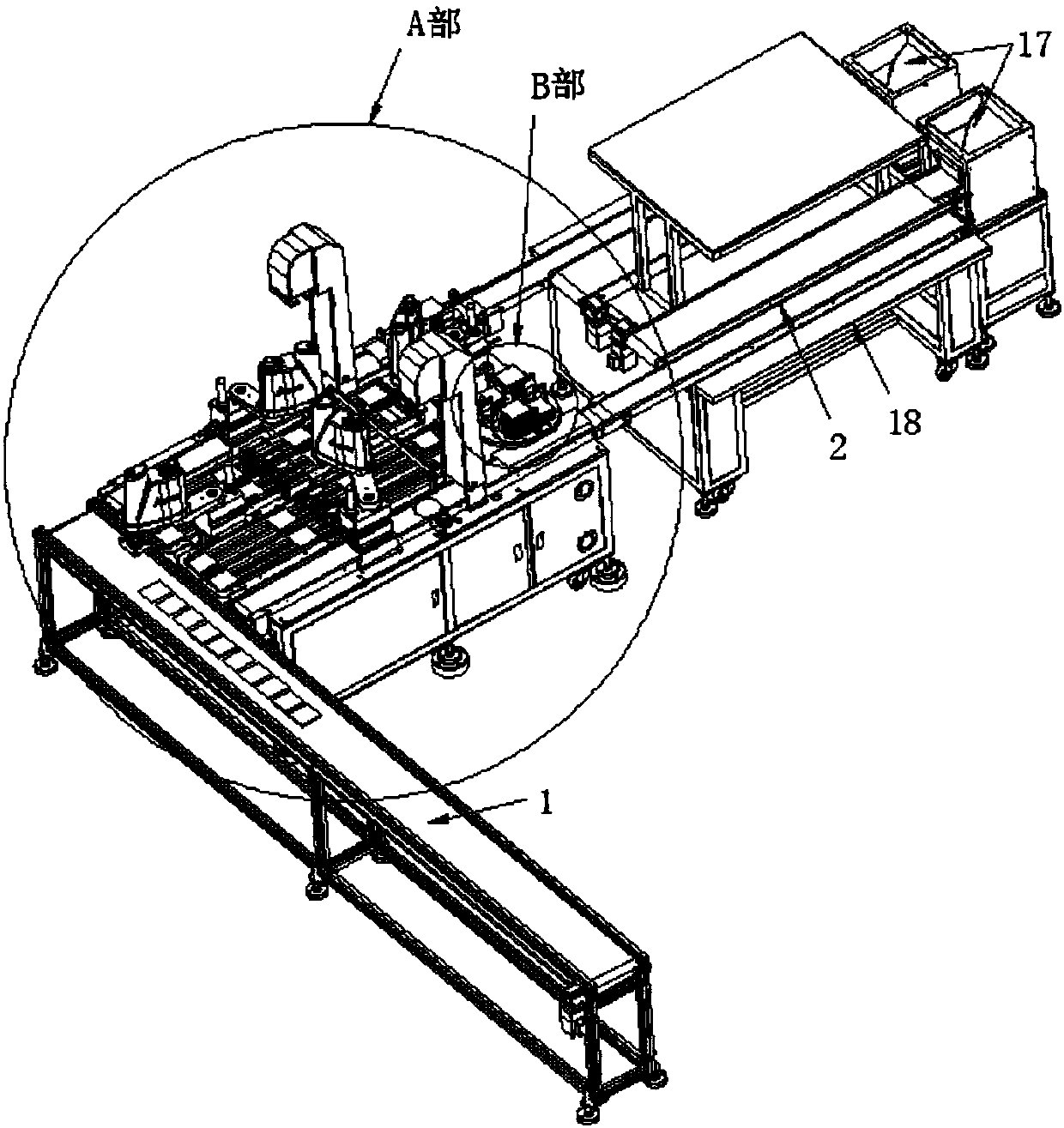

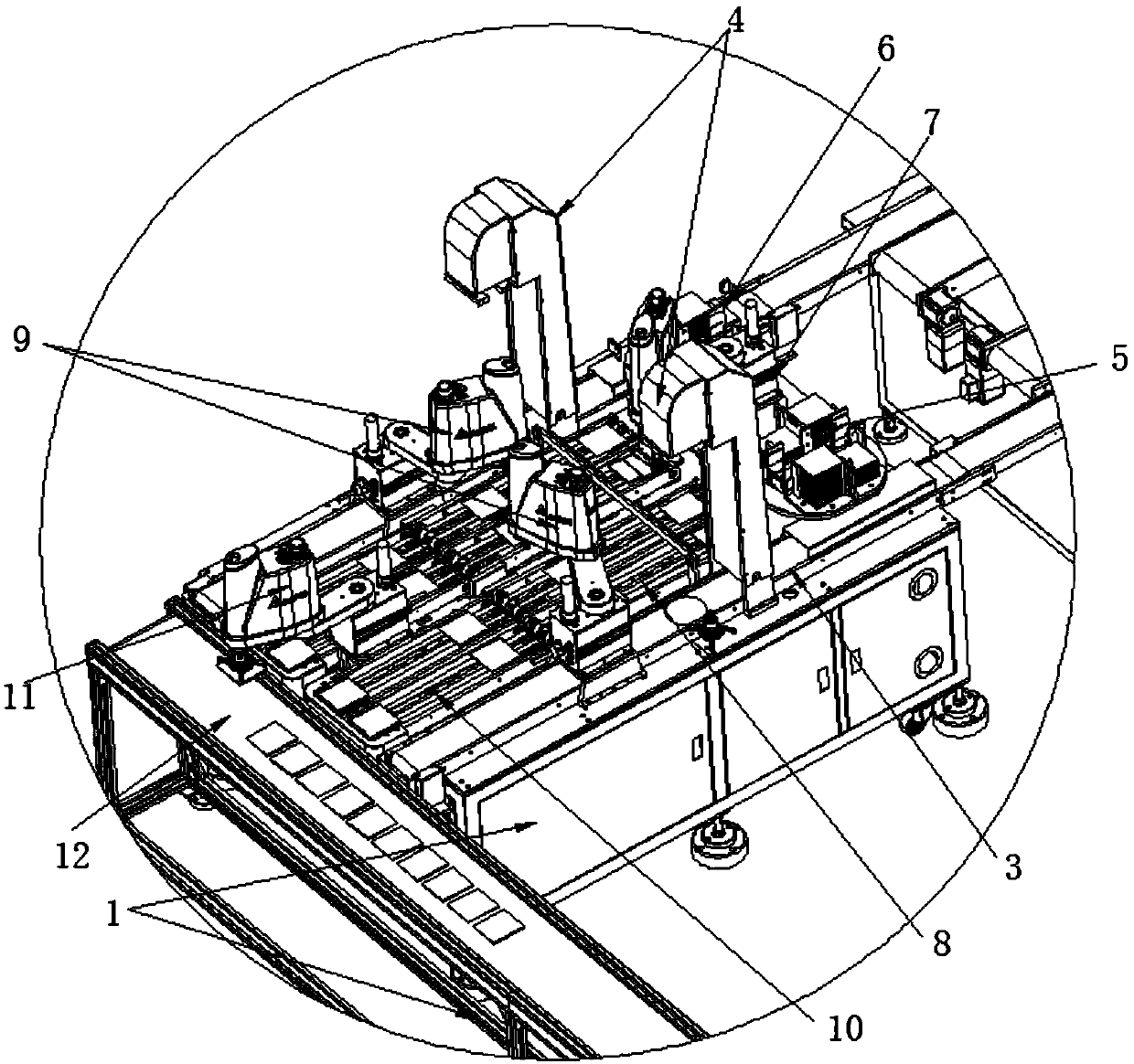

[0022] see as Figure 1-Figure 4 As shown, the technical solution adopted in this specific embodiment is: it includes a frame main body 1, a feeding conveyor belt 2, a sorting conveyor belt 3, a visual guidance device 4, a No. 1 ceramic plate feeding mechanism 5, and a No. 2 ceramic plate Feeding mechanism 6, feeding four-axis robot 7, ceramic plate primary conveyor belt 8, sorting four-axis robot 9, ceramic plate secondary conveyor belt 10, unloading four-axis robot 11, unloading conveyor belt 12, industrial computer 13 and a safety shield 14; the frame main body 1 is in an "L" shape, and the front and rear sides of the entrance are fixed with sorting conveyor belts 3 by screws, and each sorting conveyor belt 3 is equipped with a visual guide device 4, and the bottom end of the visual guidance device 4 is fixed on the entrance edge of the frame main body 1 through bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com