Hydraulic Cylinder Block Forging Machine

A forging machine and hydraulic cylinder technology, which is applied in the direction of piercing presses, forging presses, etc., can solve the problems of large impact force and inaccurate processing dimensions, and achieve reduced impact force, avoiding deformation of parts, and stable power transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

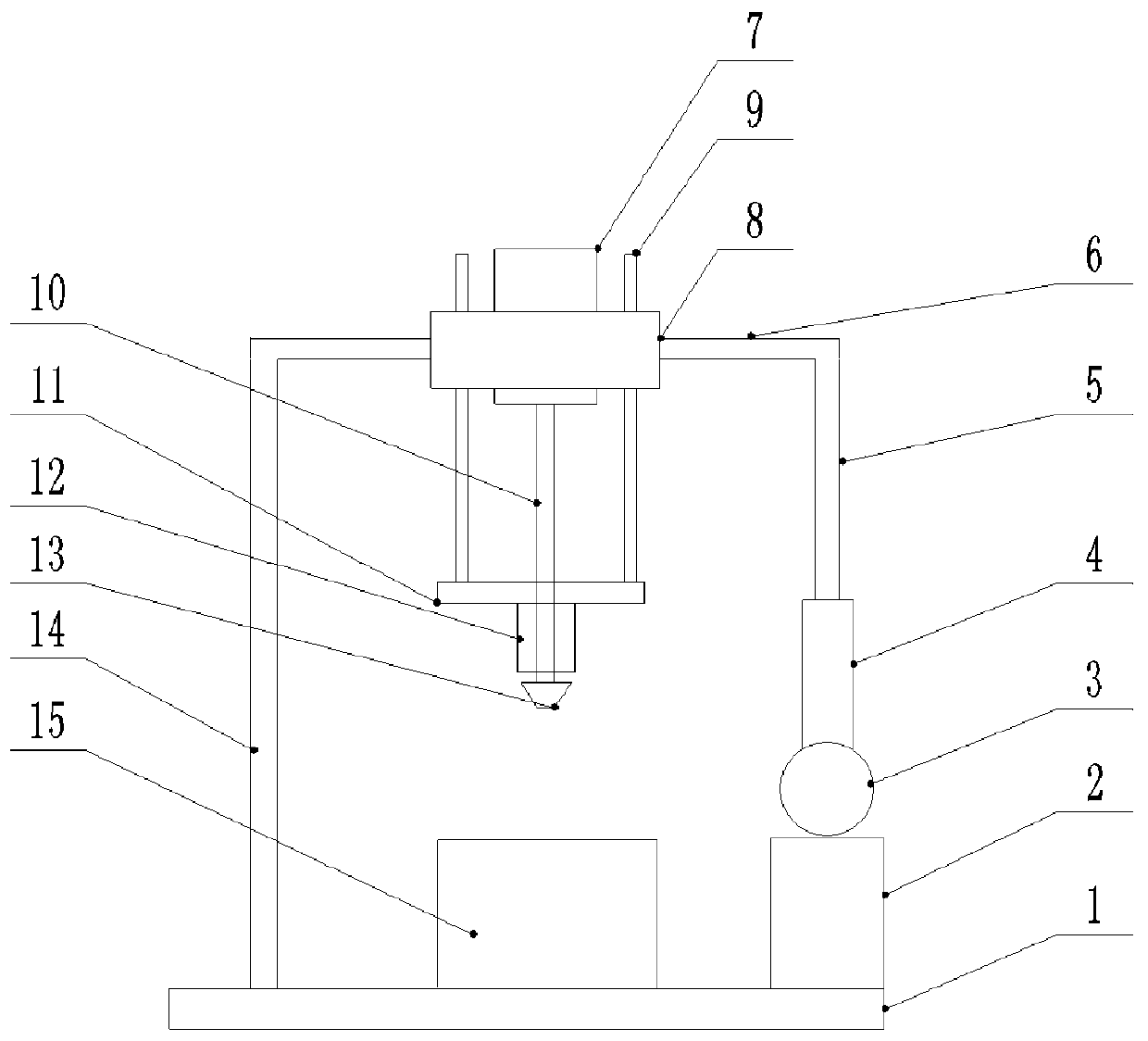

[0022] like figure 1 As described above, the hydraulic cylinder block forging machine of the present invention includes: a base 1, a guide rail 14 is installed on the left end of the base 1, a hydraulic oil tank 2 is installed on the right end, a clamping device 15 is installed in the middle of the base 1, and a Oil pump 3 and telescopic rod 4, support rod 5 is installed on the upper end of telescopic rod 4, cross beam 6 is installed between support rod 5 and guide rail 14, cross beam 6 and guide rail 14 sliding connection, support frame 8 is installed on cross beam 6, stepping Motor 7 is installed on the support frame 8, and the bottom of the rotating shaft 10 of stepping motor 7 is equipped with support plate 11, and cutter head 13 is installed on rotating shaft 10 ends, and cutter head 13 is slidably connected on the rotating shaft 10 of stepping motor 7, in A seamless steel pipe 12 is installed between the cutter head 13 and the support plate 11, and the seamless steel pip...

Embodiment 2

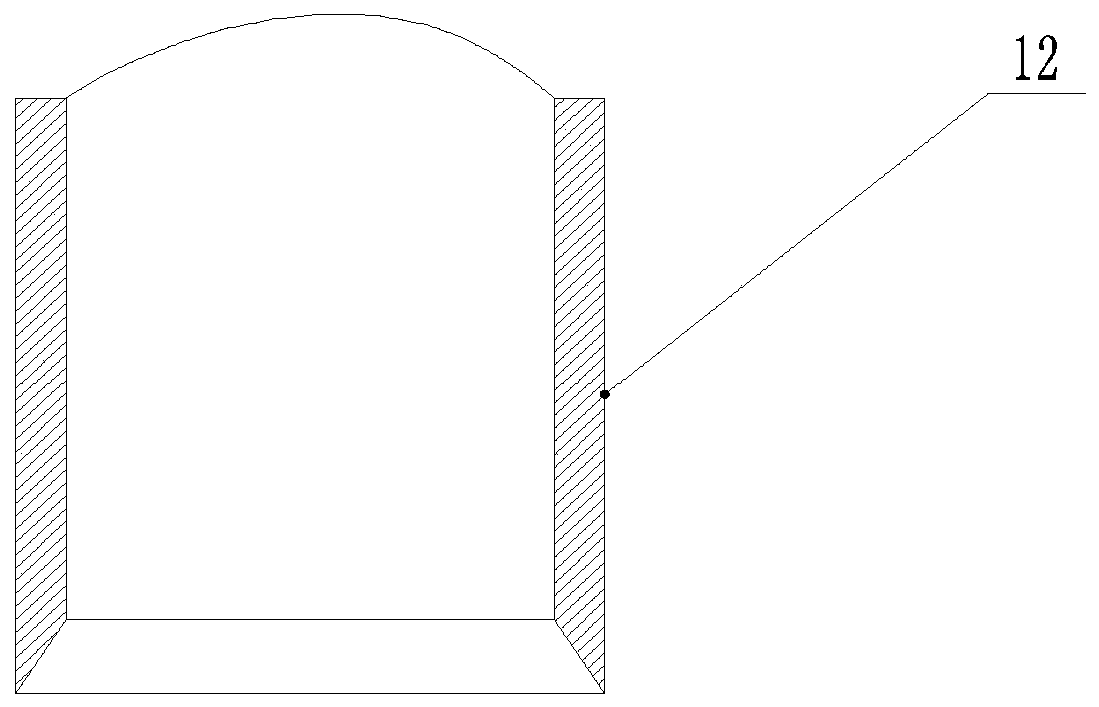

[0025] like figure 2 As shown, on the basis of Embodiment 1, the punching end of the seamless steel pipe 12 is processed into a wedge shape, which can reduce resistance when punching parts, and facilitate punching off the convex part on the hole wall.

Embodiment 3

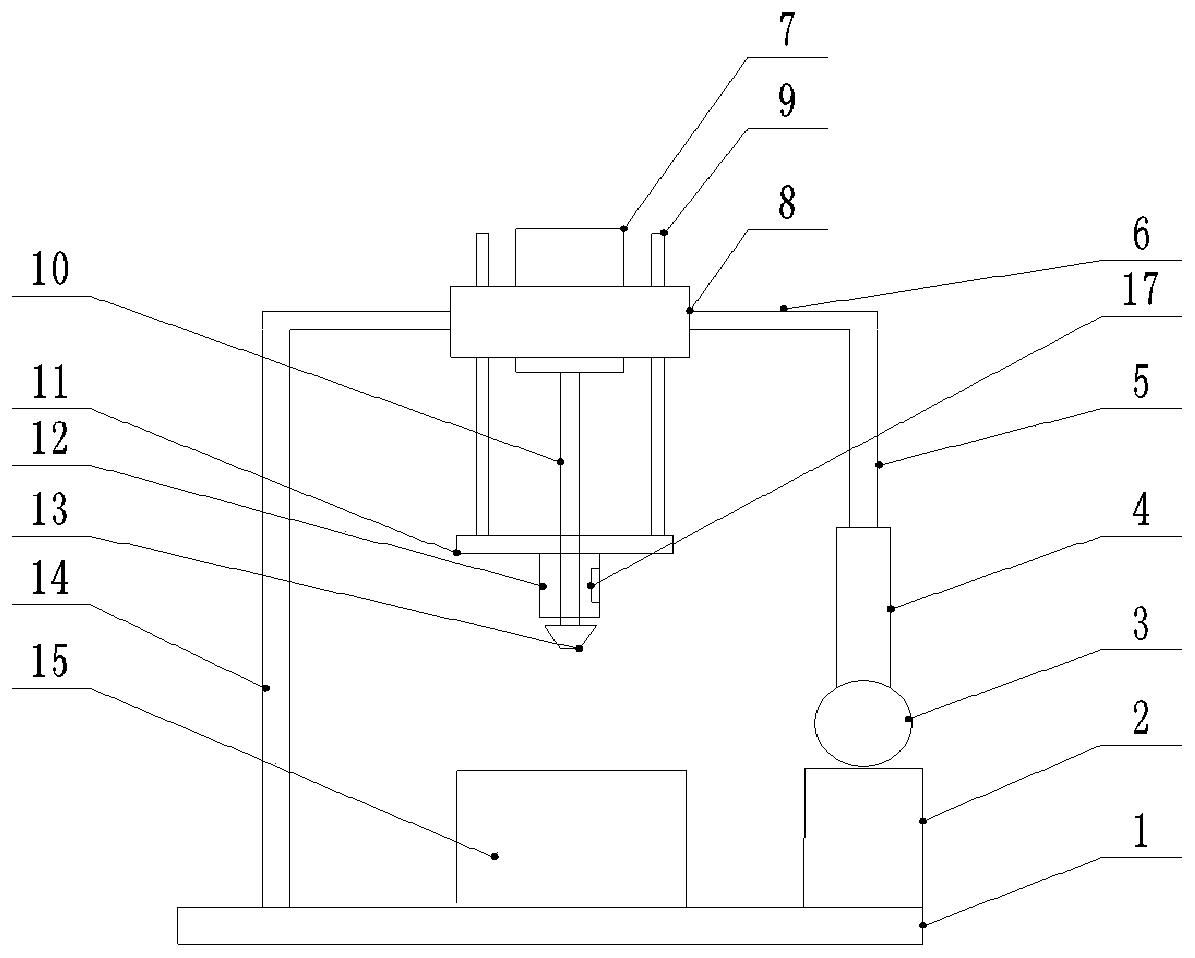

[0027] like image 3 As shown, on the basis of Embodiment 2, a bar magnet 17 is fixedly installed on the inner wall of the seamless steel pipe 12, and when the seamless steel pipe 12 is punched, the bar magnet 17 can absorb debris in the hole to Around the seamless steel pipe 12, when the expansion rod 4 rises, the debris can be taken out of the punched hole, which is convenient for cleaning the debris; bearings are installed at the junction of the crossbeam 6 and the guide rail 14, so that the resistance is reduced when the crossbeam 6 moves up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com