Heating component of warming product, preparation method and application of heating component

A technology for heating elements and products, applied in ohmic resistance heating parts, applications, electrical components, etc., can solve the problems of unstable power and power consumption rate, affecting the durability of carbon fiber, not having full sealing, etc., to save electricity Quantity, easy industrial automation production, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 Structure of Heating Element

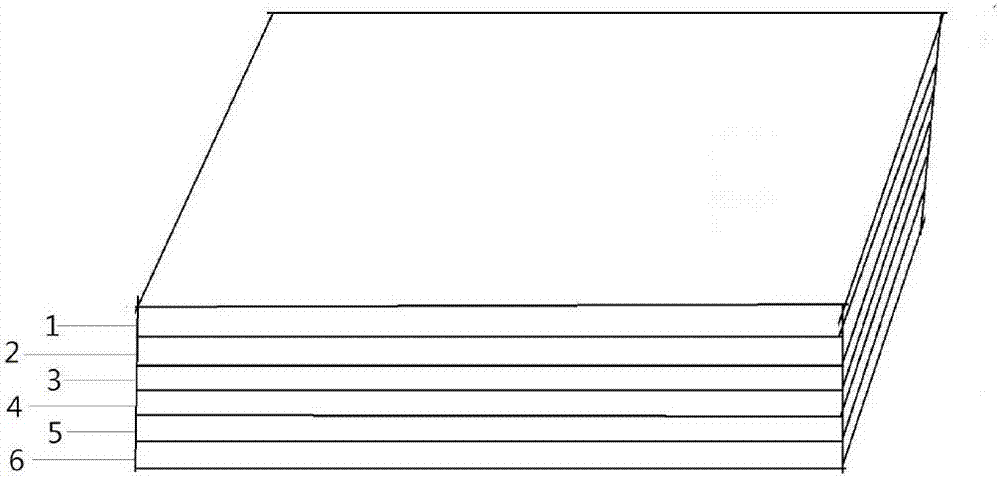

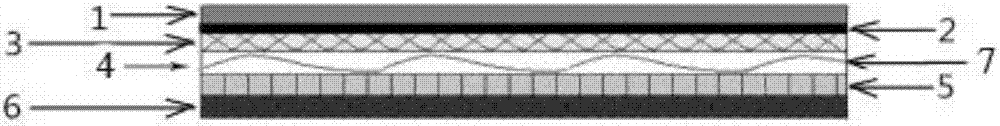

[0038] figure 1 A schematic diagram of the composite layer of the heating element. Among them, 1 is a fine denier chemical fiber fabric, 2 is a polyurethane coating, 3 is a hot-melt adhesive layer, 4 is a fabric layer containing nano stainless steel filaments, 5 is a thermal insulation layer, and 6 is a gauze fabric protective layer. figure 2It is a schematic longitudinal section view of the composite layer of the heating element of the present invention. 1 is the fine denier chemical fiber fabric, 2 is the polyurethane coating, 3 is the hot-melt adhesive layer, 4 is the fabric layer containing nano stainless steel filaments, 5 is the insulation layer, 6 is the gauze fabric protection layer, 7 is the nano Stainless steel filament. The heating element is completed by the outer layer of fine denier chemical fiber fabric 1 and polyurethane coating 2 in the gluing process of fabric production. With hot-melt adhesive 3, the nan...

Embodiment 2

[0040] The preparation of embodiment 2 heating elements

[0041] S1. First, use a fully automatic pattern machine to embroider nano-stainless steel filaments with a length of 74cm and a diameter of μm / number of strands / number of strands: 12 / 2 / 275 on the non-woven fabric to obtain a non-woven fabric containing nano-stainless steel filaments. spinning;

[0042] S2. coat a polyurethane coating on one surface of the 40 denier chemical fiber cloth;

[0043] S3. Apply the copolyamide hot melt agent to the non-woven fabric containing nano stainless steel filaments obtained in the S1 step, and then spread the 40 denier chemical fiber cloth coated with polyurethane obtained in the S2 step, and coat the polyurethane coating surface with the copolyamide hot melt adhesive The film layer is in contact with each other, covered with wax paper, placed on a hot press machine covered with wax paper for hot pressing, so that the copolyamide hot melt adhesive film layer is completely combined wi...

Embodiment 3

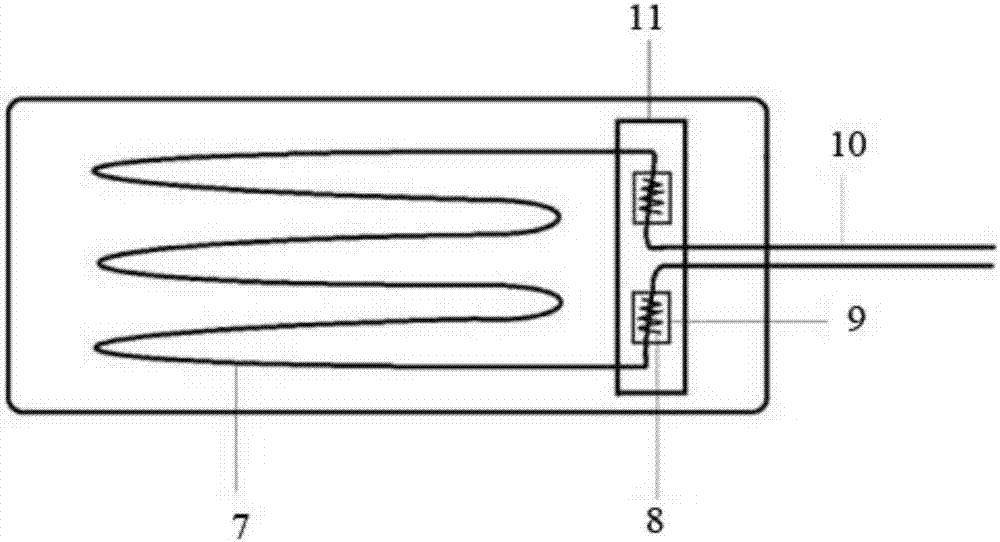

[0046] Application of embodiment 3 heating elements on thermal clothing

[0047] The heating element prepared in embodiment 2 is applied to warm clothes, such as Figure 4 shown. Wherein, 12 is a heating element, 13 is a sewing thread that the heating element is fixed on the lining in a sewing manner, 14 is an external wire for the heating element, and 15 is an external power supply. The thermal clothing includes a layer of clothing material and an electric heating element 12 . The heating element 12 is fixed on the lining by sewing, and the electric heating element 12 is provided with an external wire 10 connected to an external low-voltage power supply 15 for heating, and the low-voltage electric energy is converted into heat energy, which changes the traditional heat insulation. Method: It can provide extra heat energy in low temperature environment, ensure body temperature and increase comfort in severe cold environment, and has the advantages of fully sealed and waterpr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com