Method for manufacturing white light LED product with uniform light spots and white LED product

A production method and technology of white light, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve serious problems such as center and blue center, and achieve good sensory performance and good uniformity of light spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

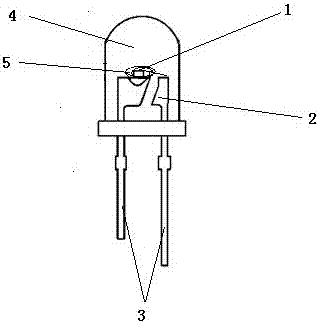

[0023] figure 1 It is a schematic diagram of the structure of the present invention, and the names marked in the figure are: LED chip 1, LAMP bracket 2, pin 3, outer sealing glue 4, and fluorescent glue 5.

[0024] The manufacturing method of the white light LED product with consistent light spots includes the following steps:

[0025] Step 1: Set the LED chip on the LAMP bracket through the crystal bonding machine with the bonding primer;

[0026] Step 2: The LED chip is connected to the positive and negative poles of the LAMP bracket through a gold wire bonding machine using wire bonding technology;

[0027] Step 3: Configure the fluorescent glue solution, and coat the fluore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com