Program control command processing method of multi-function measurement instrument

A technology of command processing and measuring instruments, which is applied in the field of program-controlled command processing of multi-function measuring instruments, can solve the problems that the syntax of multi-measurement functions cannot be recognized, the advantages of multi-threading and multi-tasking are not played, and the compatibility of multi-measurement function requirements is not considered. , to avoid the uncertainty of the instrument state, ensure the speed of command parsing, and reduce the amount of code writing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0029] 1. Multi-measurement function SCPI command analysis method

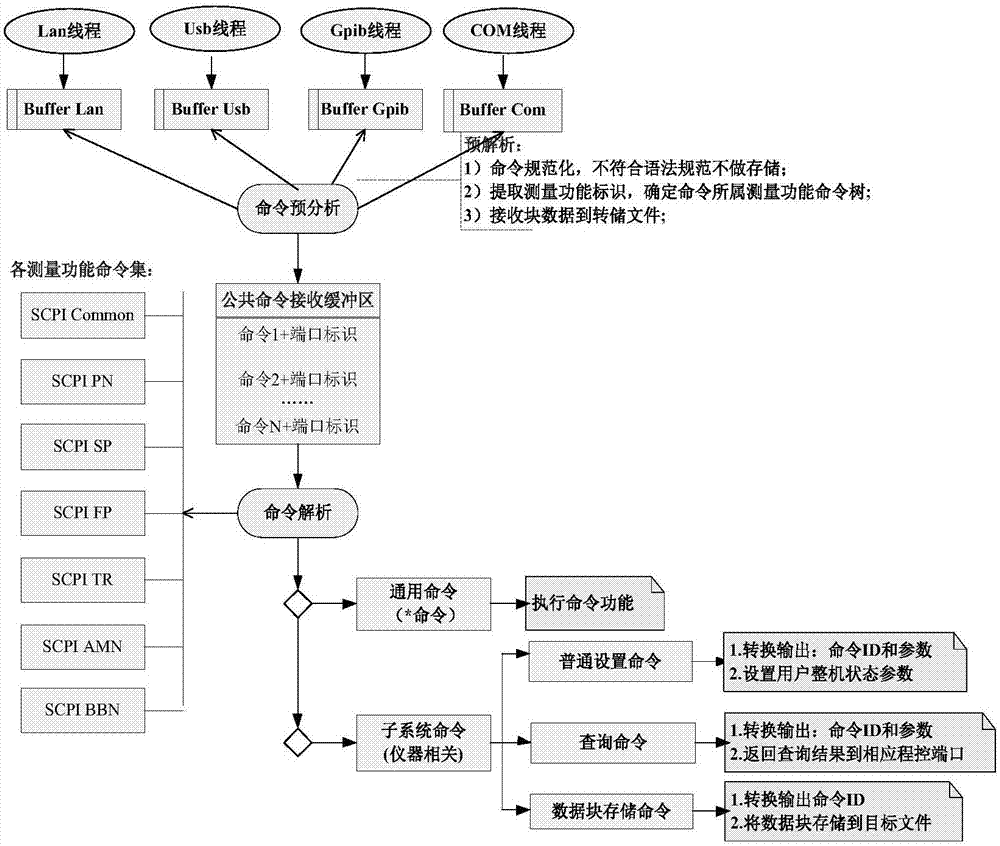

[0030] How does the program-controlled part of the multi-function measuring instrument realize the reception and analysis of multi-measurement function commands, so as to realize the equivalent function with the user interface, set the status of the user's whole machine, and then determine the final measurement status of the whole machine after further parameter adjustment. The present invention adopts the following scheme design to realize the program-controlled analysis part of multi-measurement function, as figure 1 Shown:

[0031] It can be known from the attached figure that in the program-controlled working state, the instrument runs Lan thread, USB thread, GPIB thread, and COM thread at the same time, and the four threads continuously detect whether there is command data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com