Cotton yarn dyeing production line

A production line, cotton yarn technology, applied in liquid/gas/vapor yarn/filament processing, roll textile material preservation, processing textile material carrier and other directions, can solve high cost, low production efficiency, quality defects in production and processing, etc. problem, to achieve the effect of convenient operation, simple structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

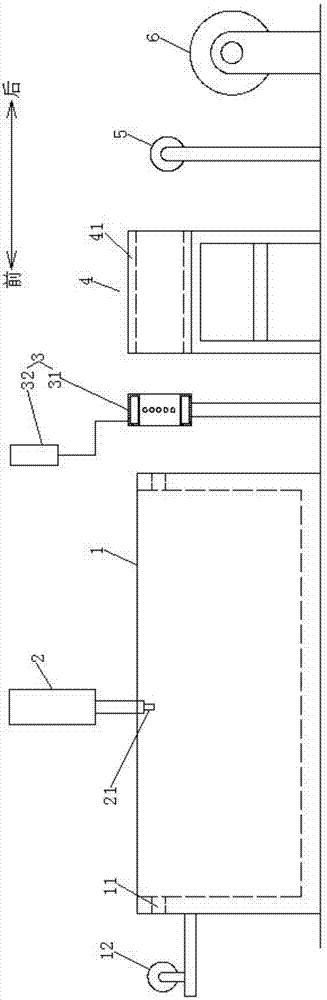

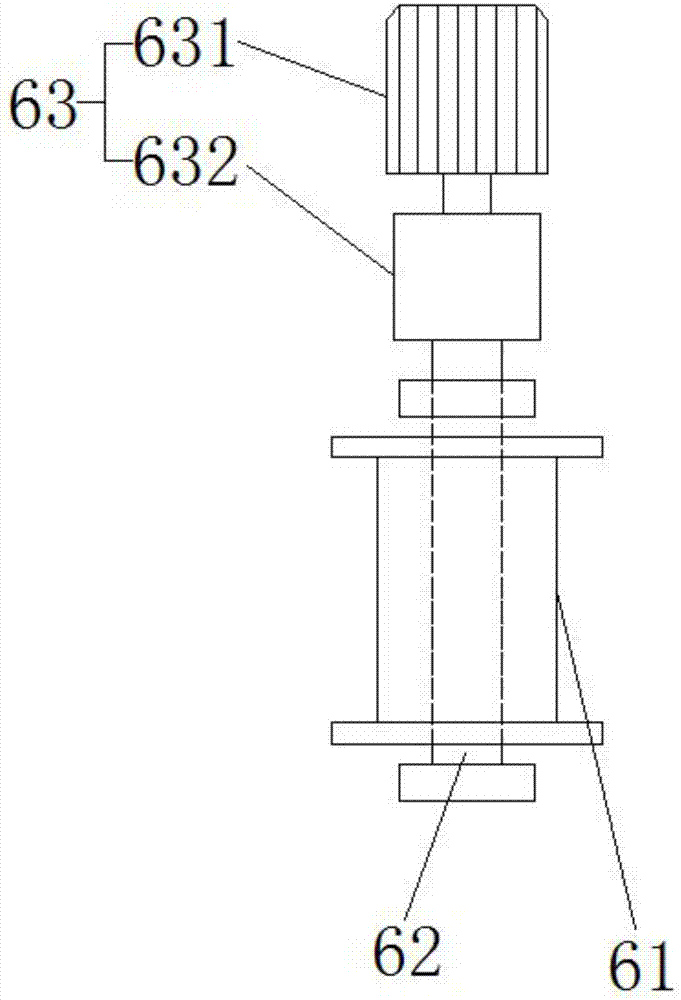

[0032] Example: such as figure 1 and 2 As shown, the cotton yarn dyeing production line of this embodiment includes a dyeing barrel 1, a dehydration device 3, a drying device 4, a guide 5 and a winding mechanism 6 fixed on the ground from front to back;

[0033] The above-mentioned dyeing barrel 1 is a barrel body with a hollow interior and an open upper end, and the upper ends of the side walls of the front and rear sides are respectively provided with thread holes 11 at the same height;

[0034] There is a dye liquor in the above-mentioned dyeing barrel 1, and the liquid level of the above-mentioned dye liquor is lower than the lower end level of the above-mentioned line hole 11;

[0035] A telescopic mechanism 2 is erected above the above-mentioned dyeing barrel 1, and the telescopic end of the above-mentioned telescopic mechanism 2 is downward and a crimping ring 21 is installed;

[0036] A guide wheel 12 is installed on the outer wall of the front side of the above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com