Preparation method of photo-thermal response nanofiber oil and water separation membrane

A technology of oil-water separation membrane and nanofiber membrane, which is applied in the field of preparation of nanofiber oil-water separation membrane with photothermal response, can solve problems such as poor strength, complicated preparation process, and limited application, and achieve high separation flow rate and high separation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

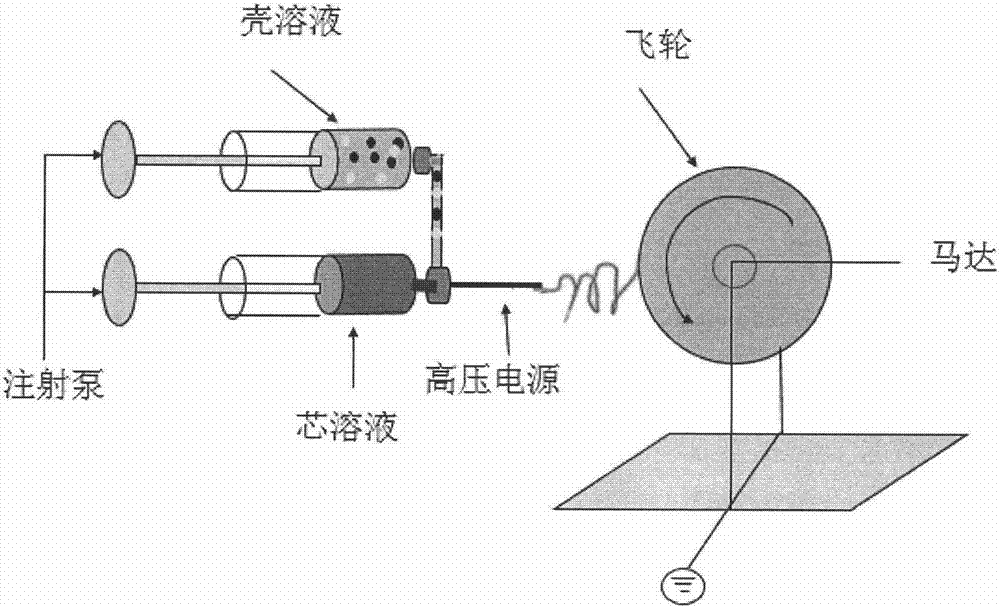

[0019] A method for preparing a photothermally responsive nanofiber oil-water separation membrane, comprising the following process steps:

[0020] (1) synthesis of polymethyl methacrylate-b-poly N-isopropylacrylamide (PMMA-b-PNIPAM); (a) synthesis of macromolecular initiator PMMA-Br, MMA (5mL, 47mmol), DMF ( 5mL), Cu(0) (15.04mg, 0.235mmol), N2H4·H2O (11.2μL, 0.235mmol), and Me 6 TREN (61.1μL, 0.235mmol) was added to a 25mL three-neck flask and stirred for 15min. Then, ethyl 2-bromoisobutyrate Eib-Br (34.4μL, 0.235mmol) was added as an initiator. The reaction was started at 90°C. Then chloroform The reacted mixture was diluted and passed through Al 2 o 3 The catalyst in the reaction is removed from the column. Finally, the macromolecular initiator PMMA-Br is obtained by methanol precipitation, and dried in a vacuum oven at 40°C. (b) Synthetic PMMA-b-PNIPAAm copolymer. Macromolecular initiator PMMA-Br (300mg, 0.025mmol), DMF / isopropanol mixed solvent (v / v%=2 / 1, 3mL), Cu(0) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com