A kind of red light-emitting glass-ceramic for white light LED and preparation method thereof

A red light-emitting, glass-ceramic technology, applied in the field of white light LED light-emitting materials, can solve the problems of increasing difficulty and cost, difficult to obtain qualified products, cold light, high color temperature and low color rendering index, etc., to reduce the probability of erosion and save money. cost, good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

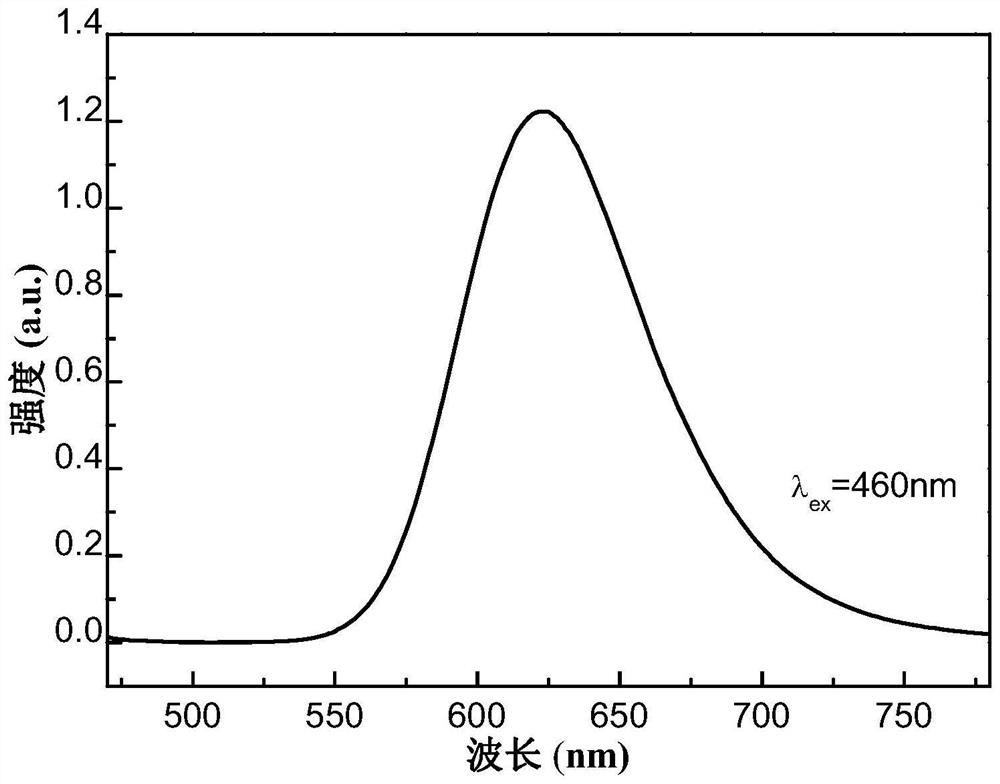

[0037] According to the mole percentage of each raw material, according to 10% Na 2 O, 20% ZnO, 30% B 2 o 3 , 20% SiO 2 , 20% of the MgO ratio is fully mixed, the raw materials are mixed evenly and then melted, the melting temperature is 1000 ℃, heat preservation for 1 hour, and the glass liquid is obtained; the glass liquid is poured into cold water, and the water quenching is carried out to obtain the transparent matrix glass ; Grind the matrix glass into powder, and mix it uniformly with the red phosphor in a mass ratio of 1:0.1, sinter in a muffle furnace at a sintering temperature of 600°C, and a sintering time of 30 minutes, and then start annealing at the glass transition temperature Tg. The temperature is lowered to 20°C at a cooling rate of 5-10°C / hour to obtain red fluorescent glass for white LEDs; the sintering method is air atmosphere sintering, and the annealing method is air atmosphere annealing.

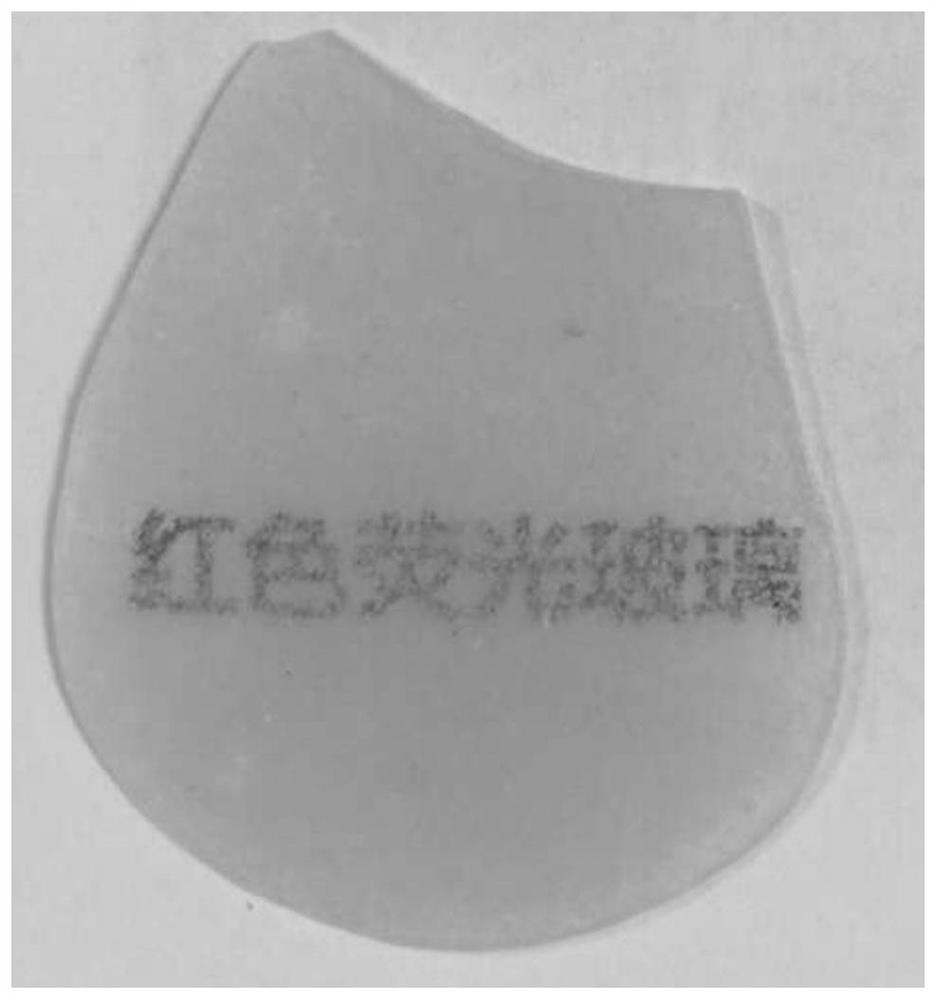

[0038] The annealed red fluorescent glass was ground and polis...

Embodiment 2

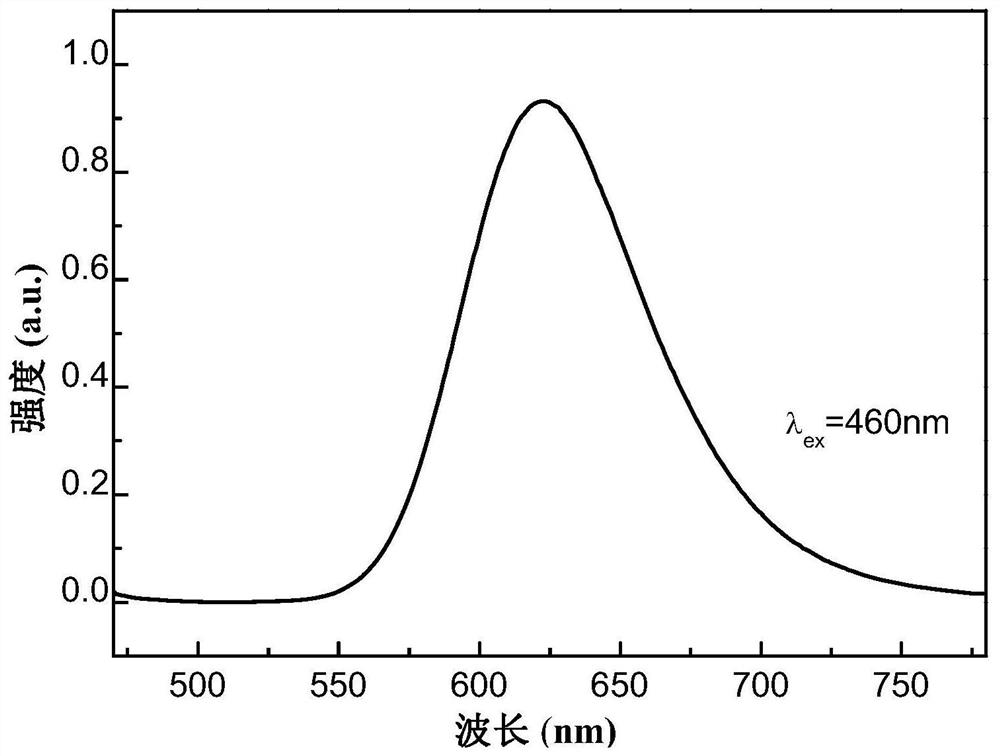

[0040] According to the mole percentage of each raw material, according to 10% Na 2 O, 20% ZnO, 30% B 2 o 3 , 20% SiO 2 , 20% of the MgO ratio is fully mixed, the raw materials are mixed evenly and then melted, the melting temperature is 1100 ℃, heat preservation for 1 hour, and the glass liquid is obtained; the glass liquid is poured into cold water, and the water quenching is carried out to obtain a transparent matrix glass ; Grind the matrix glass into powder, and mix it uniformly with the red phosphor in a mass ratio of 1:0.1, sinter in a muffle furnace at a sintering temperature of 600°C, and a sintering time of 30 minutes, and then start annealing at the glass transition temperature Tg. The temperature is lowered to 20°C at a cooling rate of 5-10°C / hour to obtain red fluorescent glass for white LEDs; the sintering method is air atmosphere sintering, and the annealing method is air atmosphere annealing.

[0041] The annealed red fluorescent glass was ground and polishe...

Embodiment 3

[0043] According to the mole percentage of each raw material, according to 15% Na 2 O, 25% ZnO, 25% B 2 o 3 , 25% SiO 2 , 10% MgO ratio is fully mixed, the raw materials are mixed evenly and then melted, the melting temperature is 1100 ℃, heat preservation for 1 hour, and the glass liquid is obtained; the glass liquid is poured into cold water, and the water quenching is carried out to obtain a transparent matrix glass ; Grind the matrix glass into powder, and mix it uniformly with the red phosphor in a mass ratio of 1:0.1, sinter in a muffle furnace at a sintering temperature of 600°C, and a sintering time of 30 minutes, and then start annealing at the glass transition temperature Tg. The temperature is lowered to 20°C at a cooling rate of 5-10°C / hour to obtain red fluorescent glass for white LEDs; the sintering method is air atmosphere sintering, and the annealing method is air atmosphere annealing.

[0044] The annealed red fluorescent glass was ground and polished to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com