Folding sand tank used for stratum fracturing

A sand tank and formation technology, applied in the field of foldable sand tanks for formation fracturing, can solve the problems of poor sealing between layers, dust, long time, etc., to reduce space occupation, easy to replace and maintain, easy to disassemble and remove Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

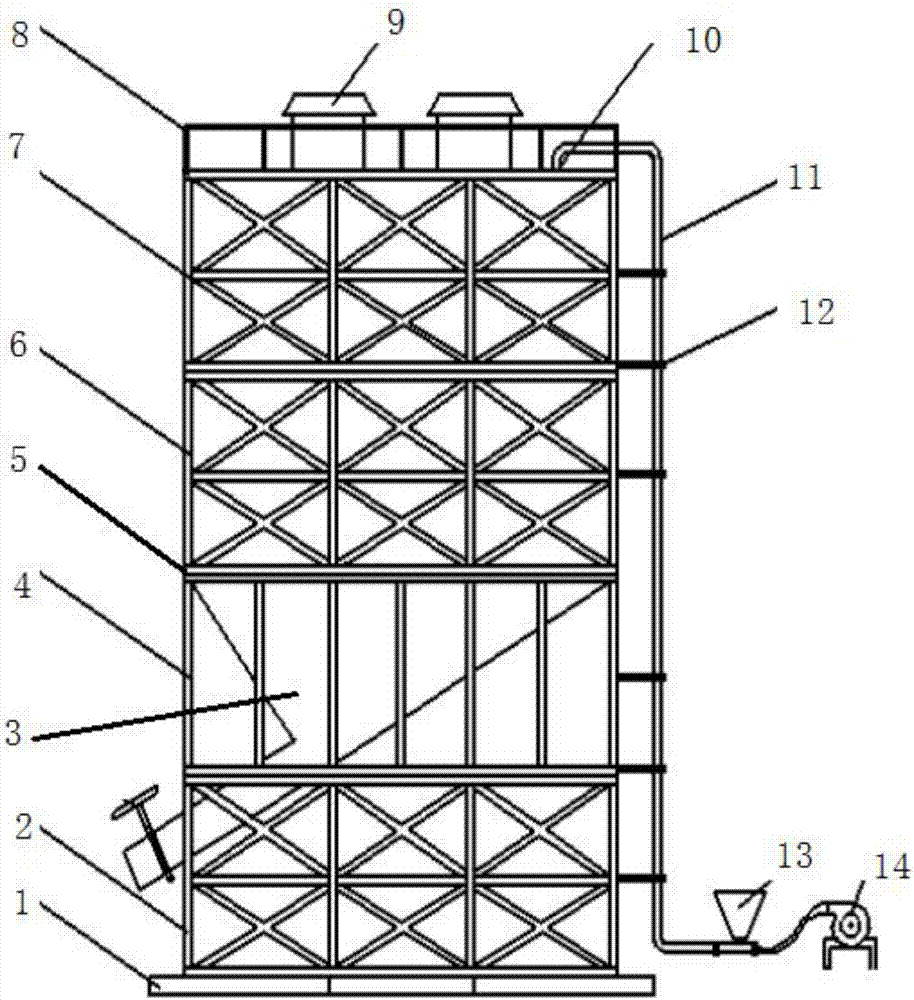

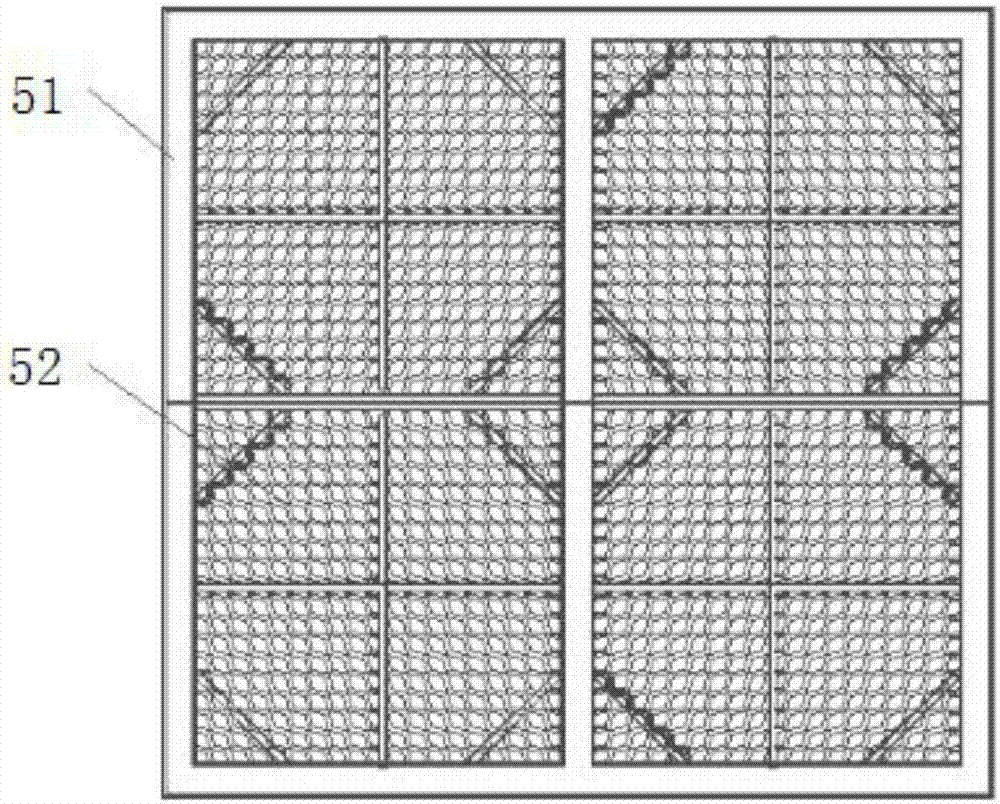

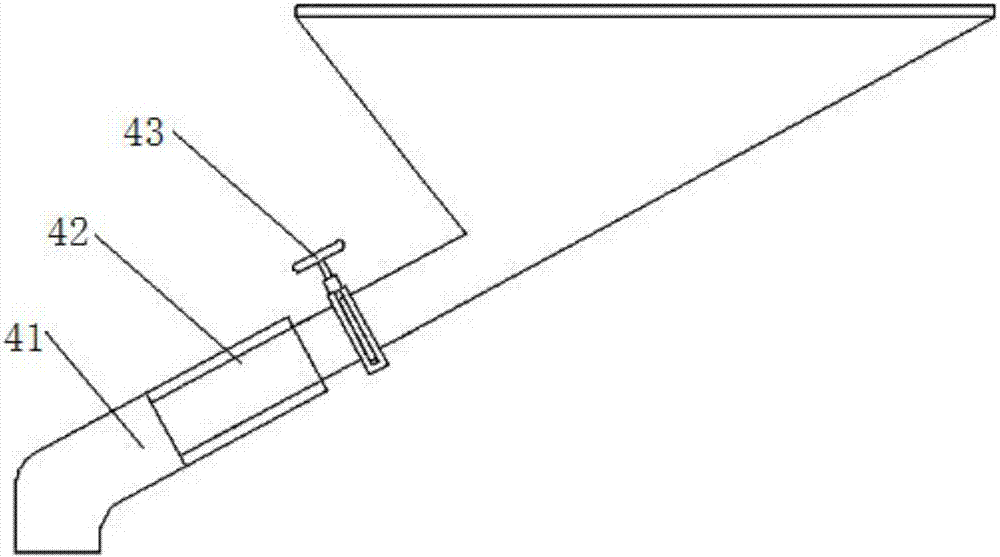

[0036] Such as Figure 1-9 As shown, a collapsible sand tank for formation fracturing includes a top layer sand storage tank 7, a second layer sand storage tank 6, and a sand leakage part 4. The main body of the sand leakage part 4 is a sand leakage section 3, and its side is a leakage Sand support, a bottom guardrail 2 is provided under the sand leakage support, and a positioning device 5 is provided between the bottom guardrail 2 and the sand leakage support. The outside of the sand storage tank 6 is wrapped with a layer of folding bracket 12, and the top of the second layer of sand storage tank 6 is connected to the top layer of sand storage tank 7 through a positioning device 5, and the outside of the top layer of sand storage tank 7 is also wrapped with a layer of folding bracket 12. The inner sides of the folding brackets 12 of the tank 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com