Rotatable clamp for circumferential hole drilling of ring-like parts with end face holes

A technology of ring parts and rotating fixtures, which is applied in the direction of metal processing machinery parts, clamping, manufacturing tools, etc., can solve the problems of poor radial hole size and position accuracy, low production efficiency, and failure to meet process requirements, etc., to achieve Improve processing accuracy, improve production efficiency, and shorten the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

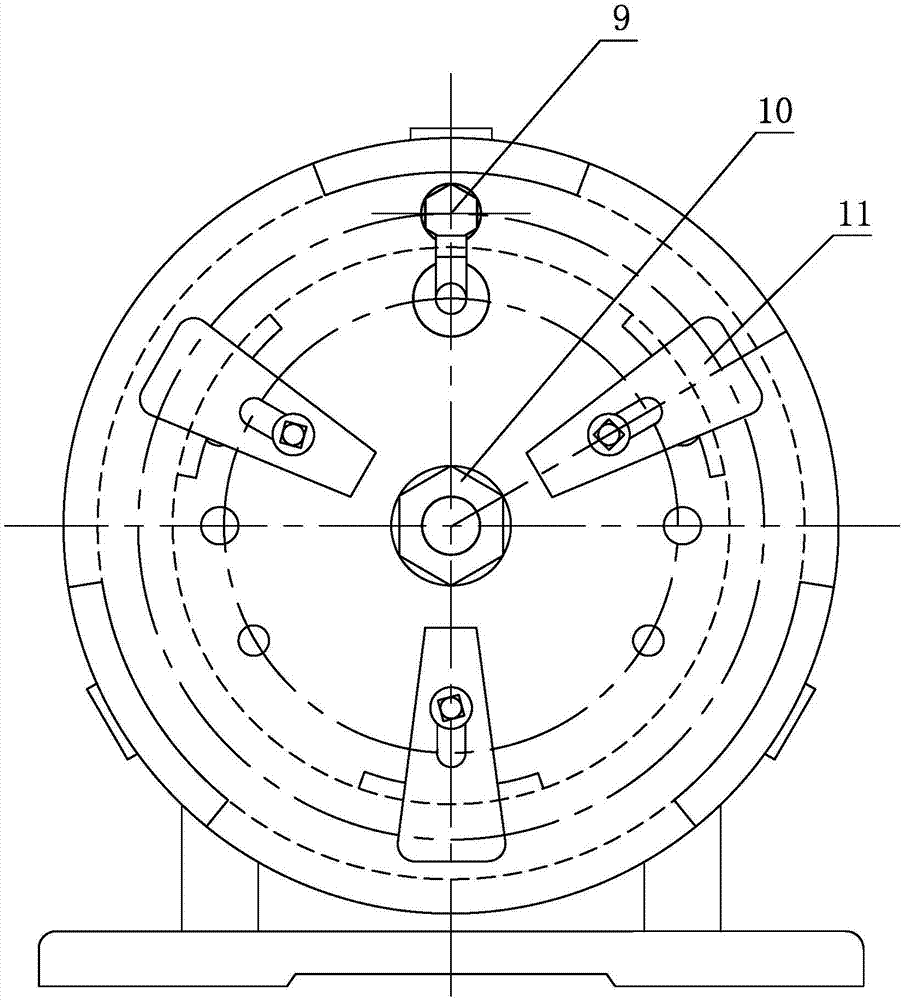

[0020] Specific implementation mode one: combine Figure 1 to Figure 10 Describe this embodiment, a rotatable fixture for drilling peripheral holes on ring parts with end face holes in this embodiment, it includes a base 8, a support 5 and a clamp body, the base 8 is set horizontally, and the support 5 is vertical It is directly fixed on the upper end surface of the base 8, and it also includes a positioning pin 4, a hexagon head screw 6, a second fixing screw 9, a nut 10, three first fixing screws 7 and three pressure plates 11,

[0021] The clamp body includes a rotating clamp body 2 and a fixed clamp body 3. The rotating clamp body 2 and the fixed clamp body 3 are positioned and installed on the support 5 through the hexagon head screw 6 and the nut 10 in turn. The rotating clamp body 2 includes three arc-shaped fixing plates 13 and three drill sleeve support seats 14, three arc-shaped fixed plates 13 are affixed to one side end face of the rotating clamp body 2 in the form...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 , Figure 5 , Figure 6 , Figure 9 and Figure 10 Describe this embodiment, present embodiment also comprises three drill sleeves 1, and three drill sleeves 1 are respectively installed in the borehole 14-1 of three drill sleeve support bases 14. Arranged in this way, the light hole D of the workpiece 12 is drilled through three drill sleeves 1 in the vertical direction to ensure that the center hole of the drill sleeve 1 coincides with the central axis of the drill bit, and the drill sleeve 1 plays a guiding role on the drill bit. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figures 1 to 4 and Figure 6 Describe this embodiment, the upper end of the support 5 of this embodiment processes the first screw hole, the fixed clamp body 3 is a cylindrical fixed clamp body, and the center position of the end surface of the cylindrical fixed clamp body processes the second screw through hole 3-1, The rotary clamp body 2 is a cylindrical rotary clamp body, and the middle position of the end surface of the cylindrical rotary clamp body is processed with a third screw through hole 2-1, and the hexagonal head screw 6 passes through the first screw hole and the second screw through hole 3-1 in sequence And the third screw passes through the hole 2 - 1 and fixes the rotating clamp body 2 and the fixed clamp body 3 on the support 5 through the nut 10 . In this way, the rotating clamp body 2 and the fixed clamp body 3 are integrally fixed on the support 5 by the hex head screw 6. When the positioning pin 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com