The method of testing the performance of concrete admixture by mortar method

A concrete admixture and concrete technology, which is applied in measuring devices, flow characteristics, instruments, etc., can solve the problems of large amount of materials used, many personnel required, and lack of specificity, and achieves small error in the mortar detection test, accurate test results, and high test results. big error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

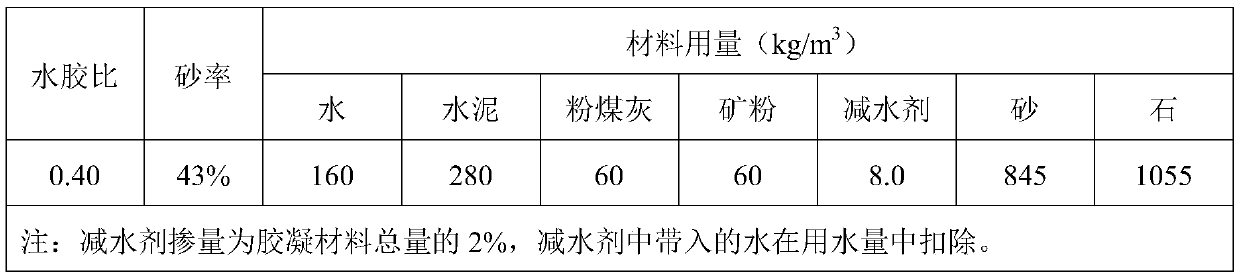

[0054] 1. Set the concrete base mix ratio as

[0055] Table 1

[0056]

[0057] The particle size distribution of the aggregate is:

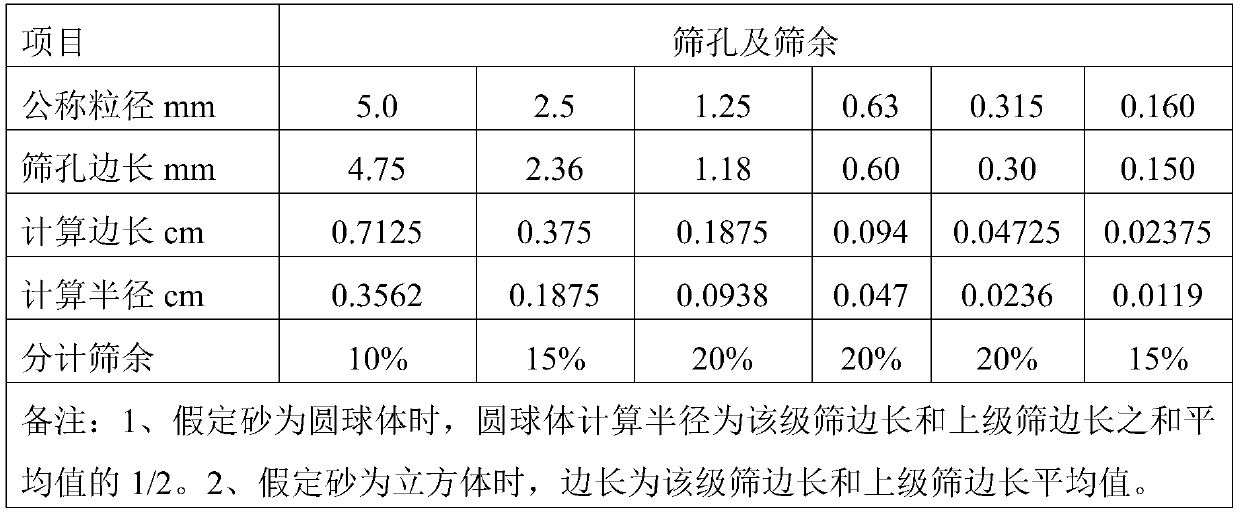

[0058] (1) Sand Table 2

[0059]

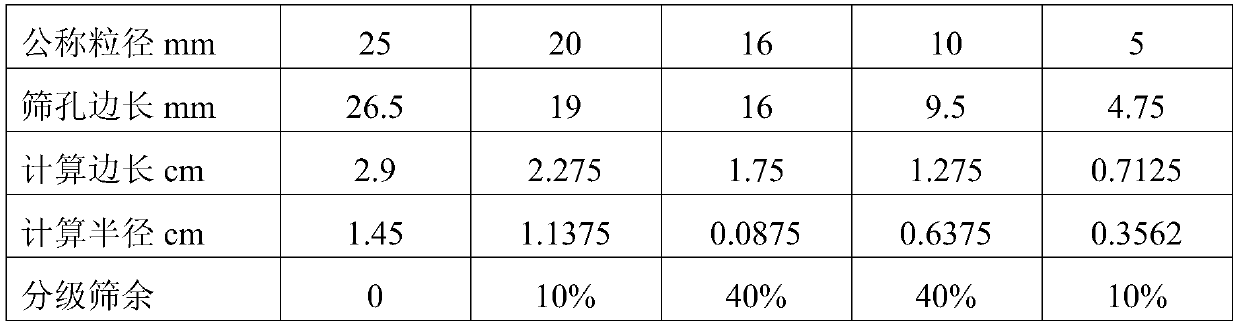

[0060] (2) Stone Table 3

[0061]

[0062]

[0063] (3) Calculation of K value (round sphere)

[0064]Among them, the percentage of sand particles with a particle size of 5mm and above measured by sieve analysis is 10%, that is, A=10%, and the calculated K value is:

[0065] K=〔∑(β g ÷r g )÷(1+A)〕÷〔∑(β s ÷r s )÷(1-A)〕×100%

[0066] =[0.1÷2.275+0.4÷1.75+0.4÷1.275+0.1÷0.7125+0.1÷0.7125〕÷(1+0.1)÷〔0.15÷0.375+0.2÷0.1875+0.2÷0.094+0.2÷0.04725+0.15÷0.02375〕 ÷(1-0.1)×100%

[0067] =[(0.0440+0.2286+0.3137+0.1404+0.1404)÷1.1〕÷[(0.4000+1.0667+2.1277+4.2328+6.3158)÷0.9〕×100%

[0068] =0.7883÷15.7144×100%=5.0%.

[0069] Note: The side length L of the cube and the radius r of the sphere are multiples, and the calculation results are the same.

[0070] 2. Calculate the ratio of mortar

[0071] (1) Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com