Thermal pressure sensor

A pressure sensor and thermal sensing technology, applied in the field of sensors, can solve the problems of large upper limit of accuracy and use range, limited work of extruding air, small deformation amount, etc., to achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

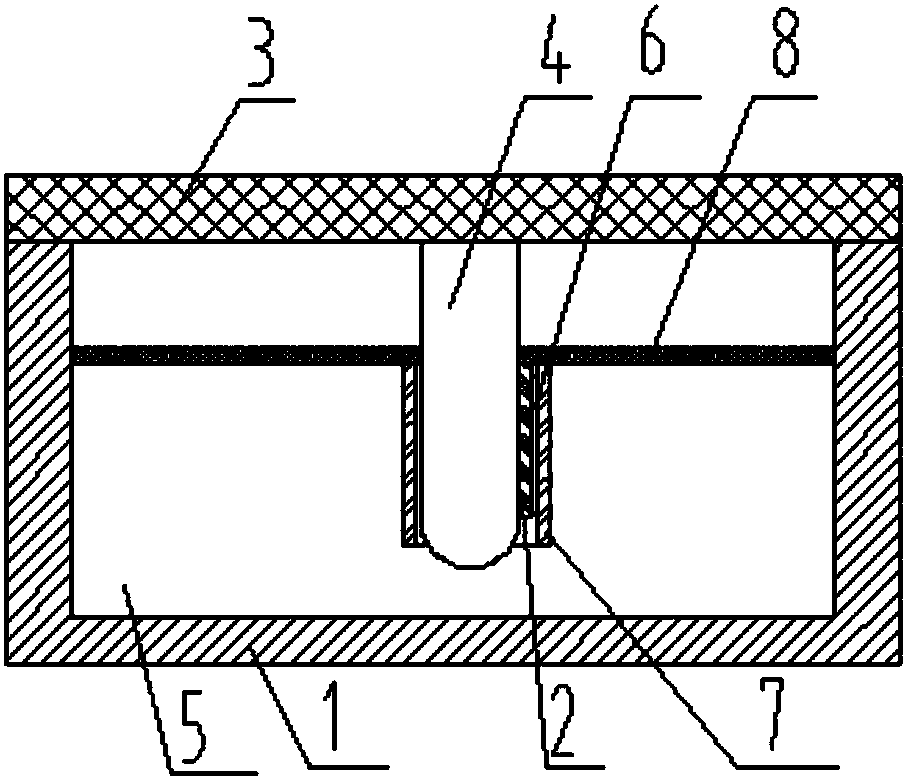

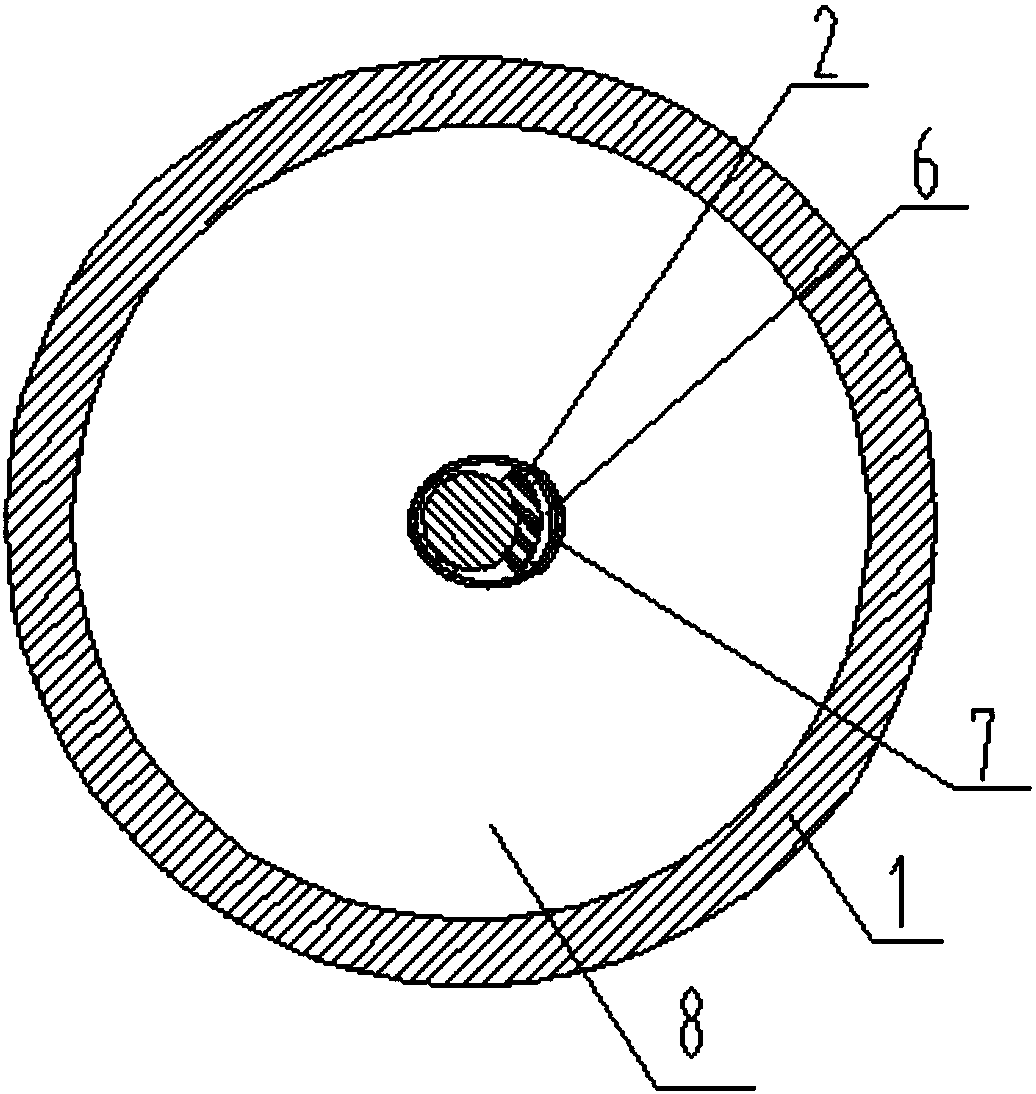

[0018] refer to figure 1 , figure 2 , a heat-sensitive pressure sensor proposed by the present invention includes: a base 1 , a heat conductor 2 , a spring cover 3 and a friction column 4 .

[0019] The base 1 is provided with a heat-resistant chamber 5 with an open top, and the thermal conductor 2 is installed on the base 1 and located in the heat-resistant chamber 5 . The spring cover 3 is installed on the base 1 and covers the opening of the heat-resisting cavity 5. By cooperating with the base 1 by the spring cover 3, the heat-resisting cavity 5 forms a sealed cavity so as to delay the heat loss in the heat-resisting cavity 5 . In this embodiment, the inner wall of the heat-resistant chamber 5 is coated with a heat-insulating layer to further improve the ability of the heat-resistant chamber 5 to retain heat.

[0020] The friction column 4 is installed on the spring cover 3 and inserted into the heat-resistant cavity 5 . The thermal conductor 2 abuts against the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com