Preparation method of graphene flame retardant chinlon

A graphene and graphene coating technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, single-component polyamide man-made filaments, etc., can solve the problem of poor durability of the flame-retardant effect of nylon fibers, difficulty in industrialized production, and complicated production processes, etc. problem, to achieve the effect of good flame retardant effect, low cost and high economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

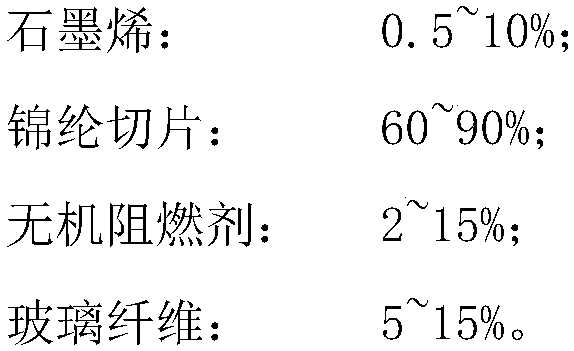

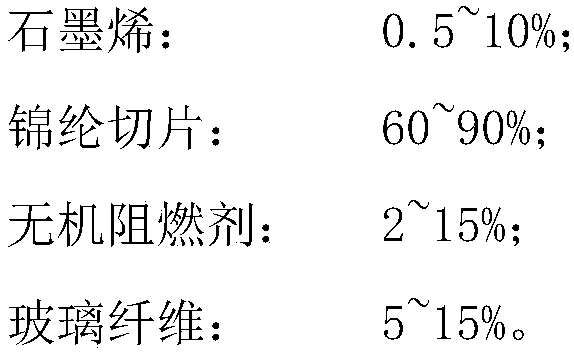

[0028] The preparation method of graphene flame-retardant nylon in the present embodiment, the prepared flame-retardant nylon fiber has high strength, high elongation at break performance and better flame-retardant effect, comprises the following steps:

[0029] Step 1: Add the coupling agent to 95% ethanol aqueous solution to obtain a treatment solution, then add graphene, inorganic flame retardant, and glass fiber to the treatment solution, and add ammonia to adjust the pH value at 10 to 12, and stir at a high speed Obtain graphene flame retardant composite material;

[0030] Step 2: After the composite material is mechanically stirred and evaporated at 80-90°C until the mixture becomes viscous, it is dried at 50-60°C for 12 hours to obtain graphene-coated inorganic flame retardant composite material powder;

[0031] Step 3: Mix nylon slices with graphene-coated inorganic flame retardant composite material powder at high speed, twin-screw extrusion, and granulate;

[0032] ...

Embodiment 1

[0047] The preparation method of graphene flame-retardant nylon in the present embodiment, comprises the steps:

[0048] Step 1: Add the coupling agent to 95% ethanol aqueous solution to obtain a treatment solution, then add graphene, inorganic flame retardant, and glass fiber to the treatment solution, and add ammonia to adjust the pH value at 10 to 12, and stir at a high speed Obtain graphene flame retardant composite material;

[0049] Step 2: After the composite material is mechanically stirred and evaporated at 80-90°C until the mixture becomes viscous, it is dried at 50-60°C for 12 hours to obtain graphene-coated inorganic flame retardant composite material powder;

[0050] Step 3: Mix nylon slices with graphene-coated inorganic flame retardant composite material powder at high speed, twin-screw extrusion, and granulate; the stirring speed of high-speed mixing is 10,000 rpm, and the stirring time is 2 minutes.

[0051]Step 4: After the nylon masterbatch is dried, it is ...

Embodiment 2

[0054] The preparation method of graphene flame-retardant nylon in the present embodiment, comprises the steps:

[0055] Step 1: Add the coupling agent to 95% ethanol aqueous solution to obtain a treatment solution, then add graphene, inorganic flame retardant, and glass fiber to the treatment solution, and add ammonia to adjust the pH value at 10 to 12, and stir at a high speed Obtain graphene flame retardant composite material;

[0056] Step 2: After the composite material is mechanically stirred and evaporated at 80-90°C until the mixture becomes viscous, it is dried at 50-60°C for 12 hours to obtain graphene-coated inorganic flame retardant composite material powder;

[0057] Step 3: Mix nylon slices with graphene-coated inorganic flame retardant composite material powder at high speed, twin-screw extrusion, and granulate; the stirring speed of high-speed mixing is 10,000 rpm, and the stirring time is 2 minutes.

[0058] Step 4: After the nylon masterbatch is dried, it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com