Medium-temperature cured prepreg resin matrix for rapid molding and preparation method of medium-temperature cured prepreg resin matrix

A resin matrix, prepreg technology, applied in the field of prepreg manufacturing, can solve the problem of slow low temperature curing reaction, achieve stable heat release, shorten the medium and low temperature curing time, and smooth the surface of the sample

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The composition of the resin matrix formula is by mass fraction:

[0046] Trifunctional glycidylamine epoxy resin MY0510: 20 parts;

[0047] Liquid bisphenol A epoxy resin 331:20 parts;

[0048] Solid bisphenol A epoxy resin 671:60 parts;

[0049] Modified imidazole LH-210: 8 parts;

[0050] Dicyandiamide 100S: 2 parts.

[0051] The preparation method of the resin matrix: break the solid epoxy resin into particles with a diameter less than 5mm, and then add each component into the container of the self-rotating and revolving vacuum mixer according to the above formula. First, stir for 3 minutes at a vacuum of 30 kPa and a rotating speed of 2000 rpm, then stir for 8 minutes at a vacuum of 0.3 kPa and a rotating speed of 2000 rpm. After the stirring is completed, an epoxy resin composition is obtained.

[0052] The preparation method of the standard spline: put the standard spline mold into the blast oven, keep it warm for 1 hour after the temperature rises to the cur...

Embodiment 2

[0055] The composition of the resin matrix formula is by mass fraction:

[0056] Liquid bisphenol A epoxy resin 331:40 parts;

[0057] Novolac epoxy resin 438: 20 parts;

[0058] Solid bisphenol A epoxy resin 671:40 parts;

[0059] Modified imidazole LH-210: 8 parts;

[0060] Dicyandiamide 100S: 1.5 parts.

[0061] The preparation method of the resin matrix and the standard spline is the same as in Example 1.

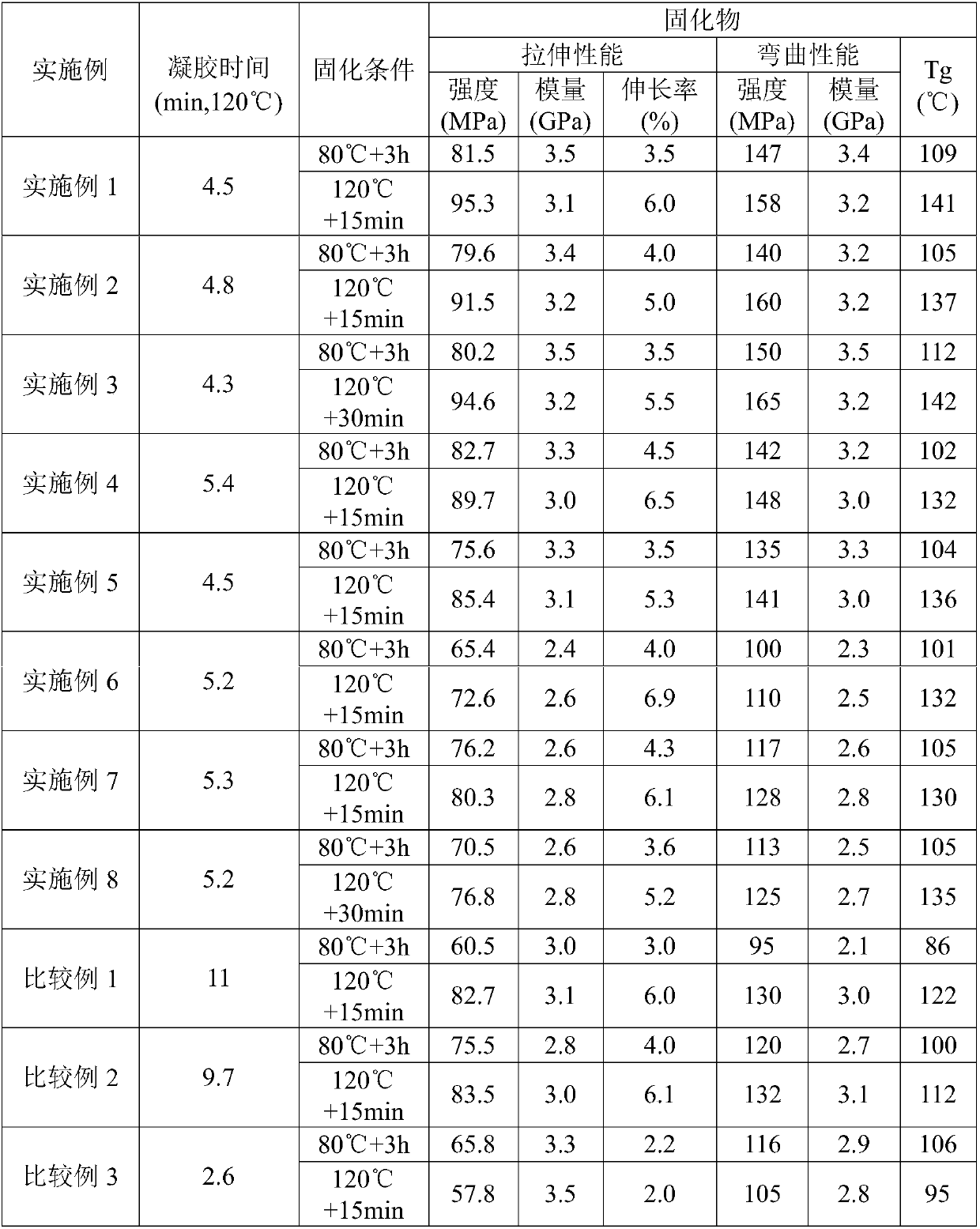

[0062] Table 1 shows the test results of the epoxy resin composition and its cured product.

Embodiment 3

[0064] The composition of the resin matrix formula is by mass fraction:

[0065] Four-functional glycidylamine epoxy resin XB9721: 20 parts;

[0066] Liquid bisphenol F epoxy resin 354:20

[0067] Solid bisphenol A epoxy resin 671:60 parts;

[0068] Modified imidazole LH-210: 8 parts;

[0069] Dicyandiamide 100S: 1.5 parts.

[0070] The preparation method of the resin matrix and the standard spline is the same as in Example 1.

[0071] Table 1 shows the test results of the epoxy resin composition and its cured product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com