Magnetic attraction type foreign matter removing device

A foreign body removal and magnetic suction technology, applied in the coating and other directions, can solve the problems of shortening the maintenance cycle of the laminating machine, affecting the quality of the finished product, frequent shutdown and maintenance, etc., to improve the risk of foreign bodies, easy and reliable use, and ensure product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For ease of understanding, the specific structure and working method of the present invention are described as follows in conjunction with the accompanying drawings:

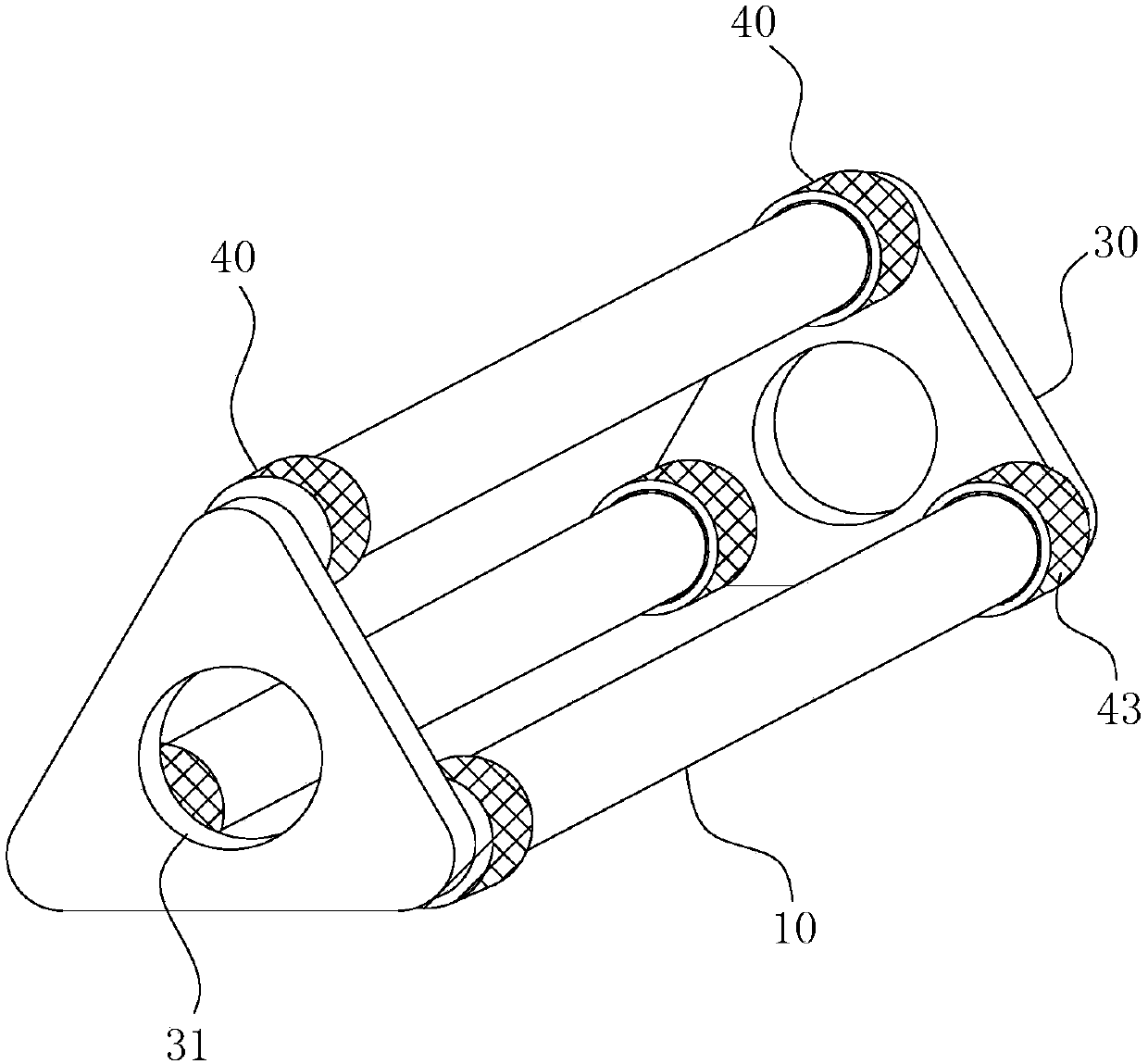

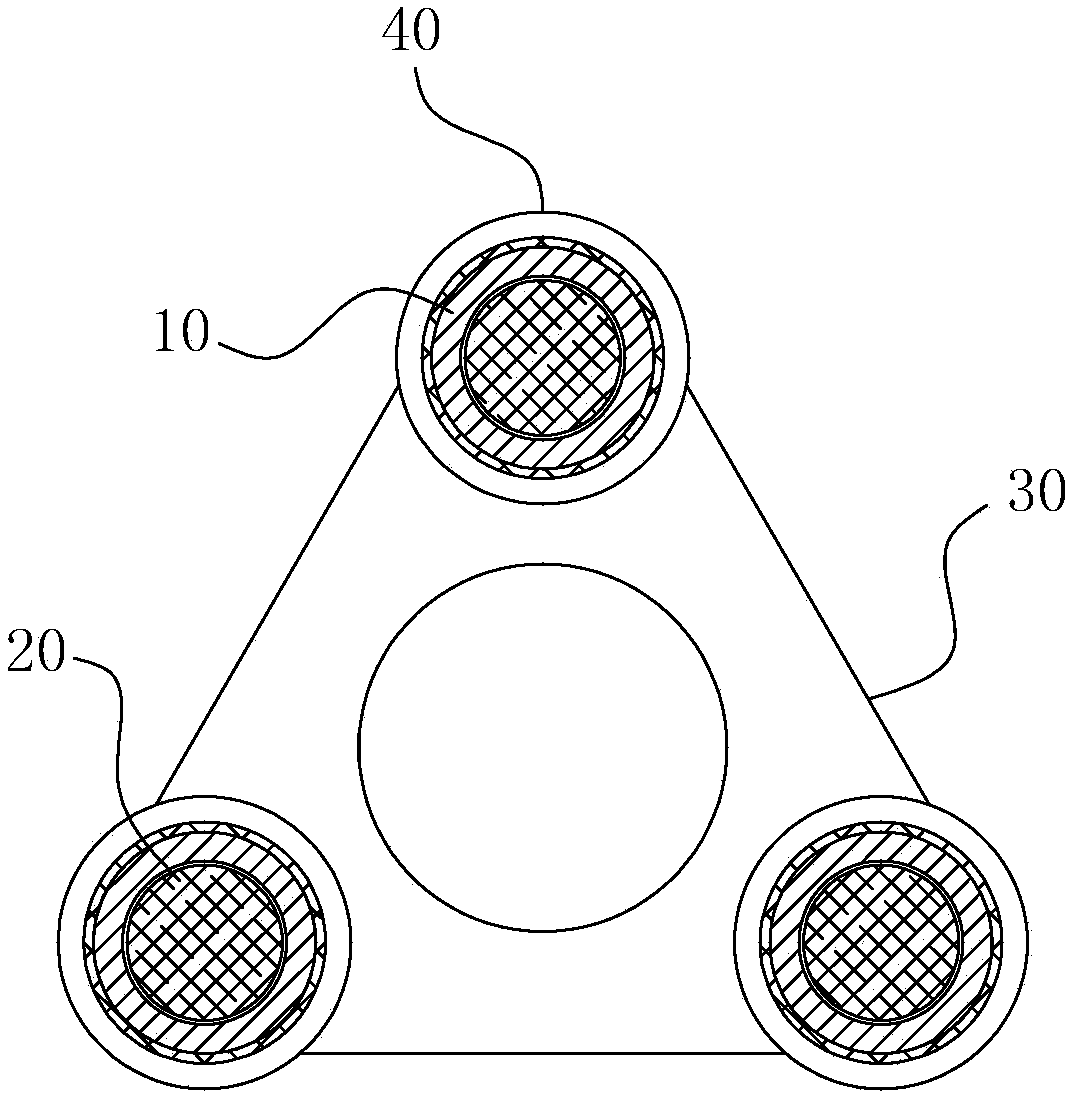

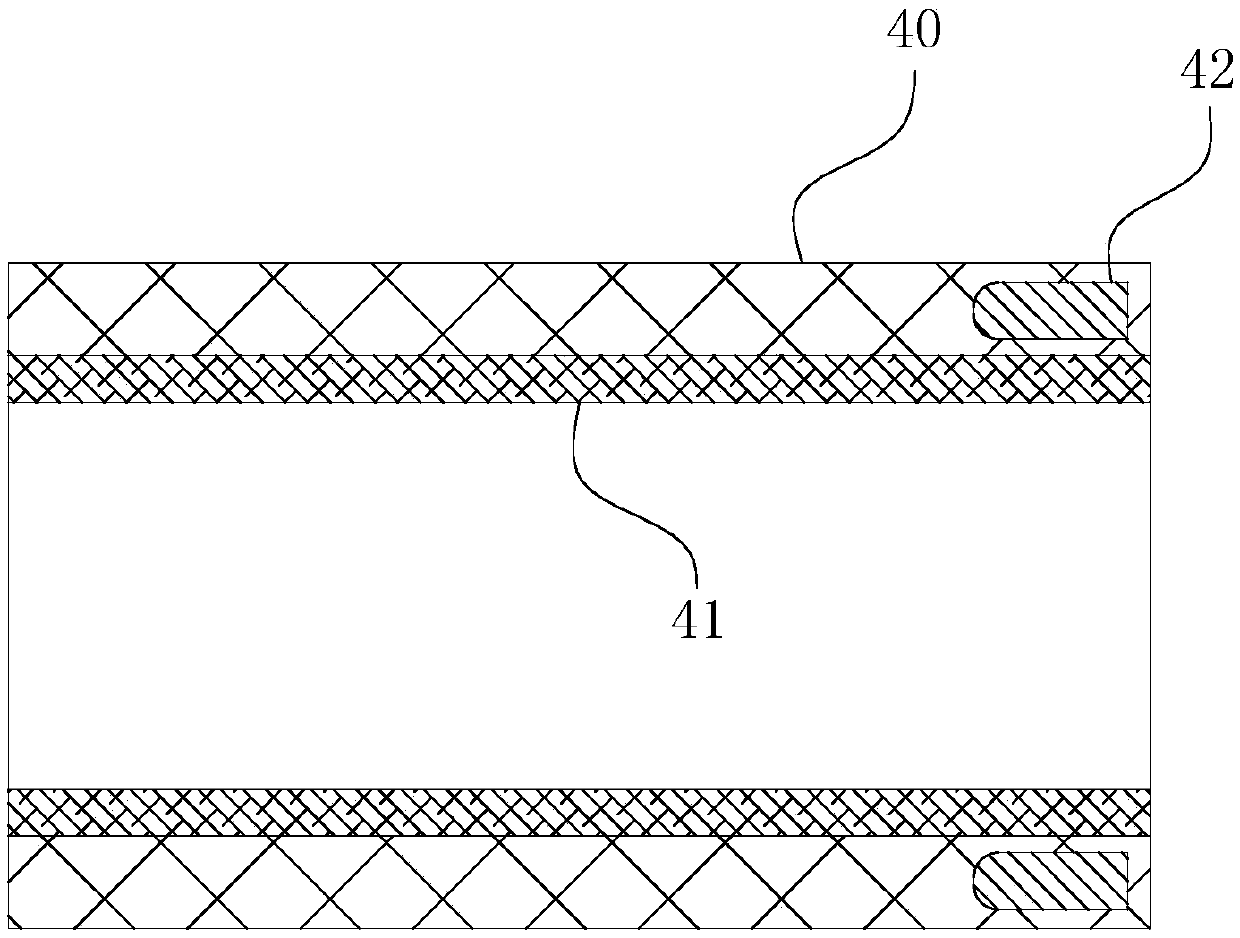

[0026] Concrete structure of the present invention refers to Figure 1-4 As shown, its main structure includes two triangular plate-shaped end sealing plates 30, three straight tube-shaped magnetic suction tubes 10, three magnetic rods as magnets 20, and six groups of cleaning cleaning tools with a gel layer or felt layer 41 on the inner ring surface. Ring 40. in:

[0027] The corner ends of the two end sealing plates 30 are all smoothly transitioned, while the three magnetic suction tubes 10 are in the shape of Figure 1-2 The shown triangular array is fixed between two end sealing plates 30 . Since the two end sealing plates 30 are parallel to each other, and the pipe ends of the three magnetic tubes 10 are welded to the corresponding end sealing plates 30, the lumens of the magnetic tubes 10 natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com