Automatic soldering and smoke eliminating device for PCB

A PCB board and automatic welding technology, applied in auxiliary devices, welding equipment, printed circuits, etc., can solve the problems of operators' physical discomfort and floating smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

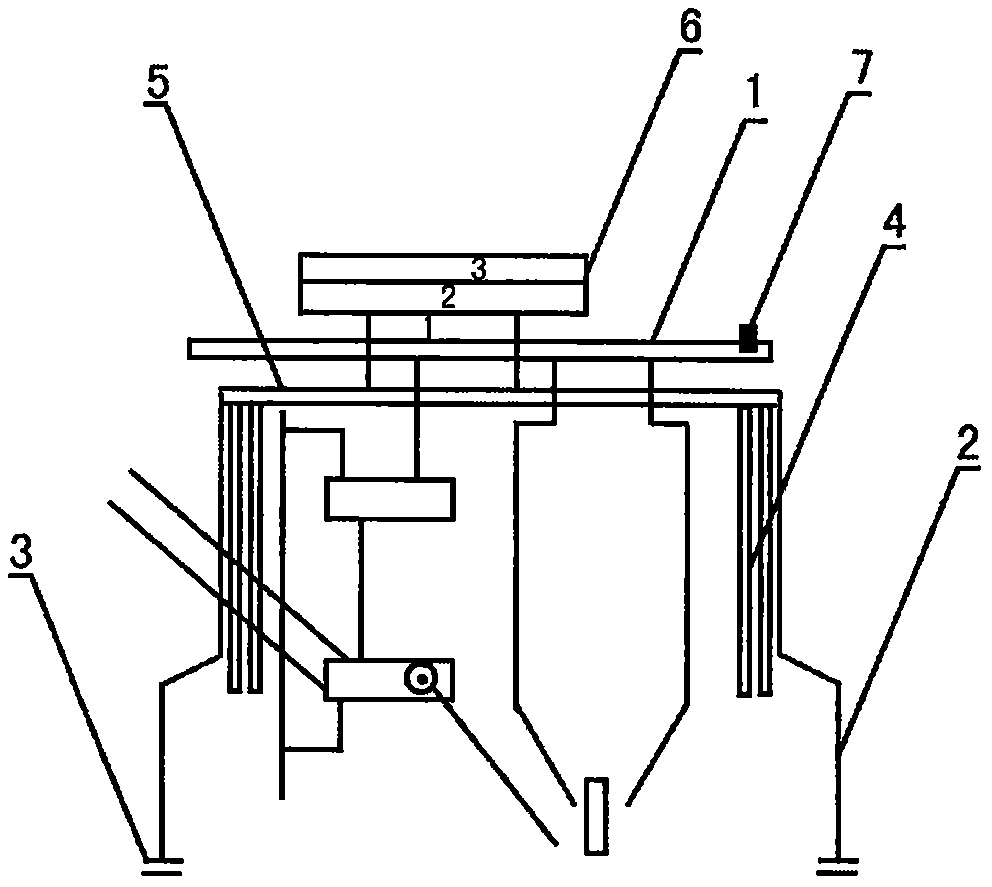

[0012] Embodiment: as shown in the accompanying drawing. An automatic soldering and smoke suppression device for PCB boards, comprising a soldering frame (1), an open type protective cover device (2) is arranged under the frame (1), an elastic gasket (3) is arranged at the bottom, and a Arranged smoking components (4) connected to the delivery pipe (5) are arranged at / 3, and the smoke generated during the soldering process is transported to the multi-stage purification treatment device (6) through inhalation during operation, and the different odors of lead smoke and other gases are treated differently. degree of elimination.

[0013] An automatic soldering and smoke elimination device for PCB boards is provided with a prompting device (7) to provide different prompts for the running and replacement states.

[0014] The invention relates to an automatic soldering smoke elimination device for PCB boards, and the information prompting mode is sound or LED light display.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com