Granulated powder removing and humidifying assembly of floor drain polishing machine

A technology of particle powder and polishing machine, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., and can solve the problem of high monitoring requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

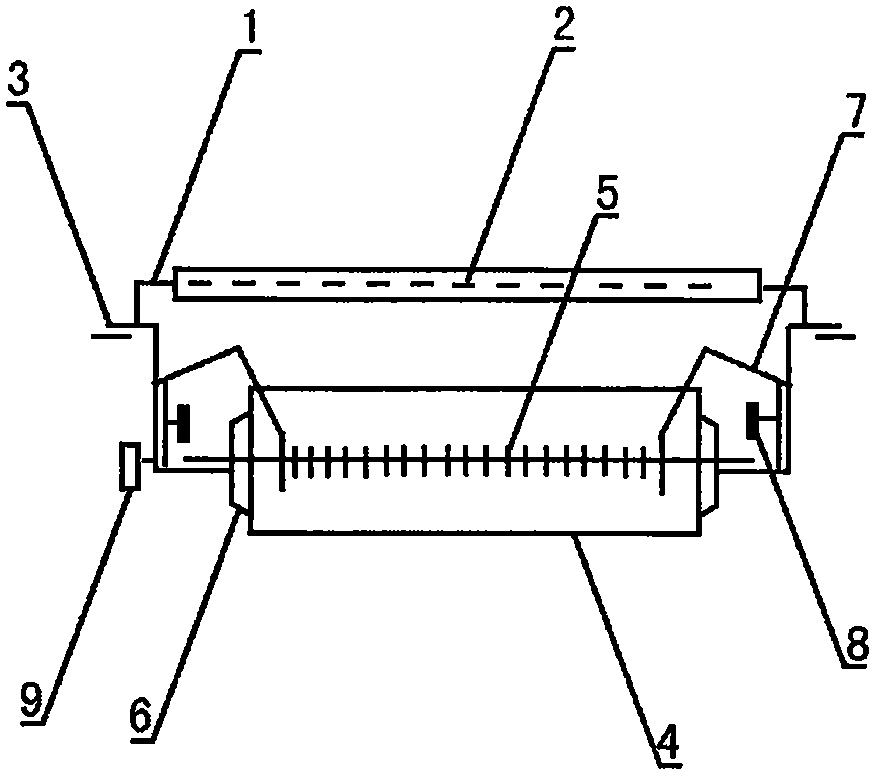

[0012] Embodiment: as shown in the accompanying drawing. A particle powder removal and humidification assembly for a floor drain polisher, comprising a frame body (1). The frame body (1) is designed in two parts. The powder parts include dust collection cover device (4), cleaning brush (5), sliding lock (6), lifting column (7), the frame body (1) is positioned in front of the polishing wheel of the floor drain polishing machine during operation, and the speed sensing device ( 8) Sensing its rotation speed, clearing the wheel surface particle powder at a fixed frequency, and performing humidification treatment if necessary.

[0013] The utility model relates to a particle powder removing and humidifying component of a floor drain polishing machine, which is provided with a prompting device (9), and the prompting information is displayed by sound or LED lights.

[0014] The utility model relates to a particle powder removing and humidifying component of a floor drain polishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com