Scald-avoiding type derusting assembly of plastic wire drawing machine

A plastic wire drawing machine and wire drawing machine technology, applied in the field of wire drawing machines, can solve the problems of easy splashing of boiling water, rust, and insufficient safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

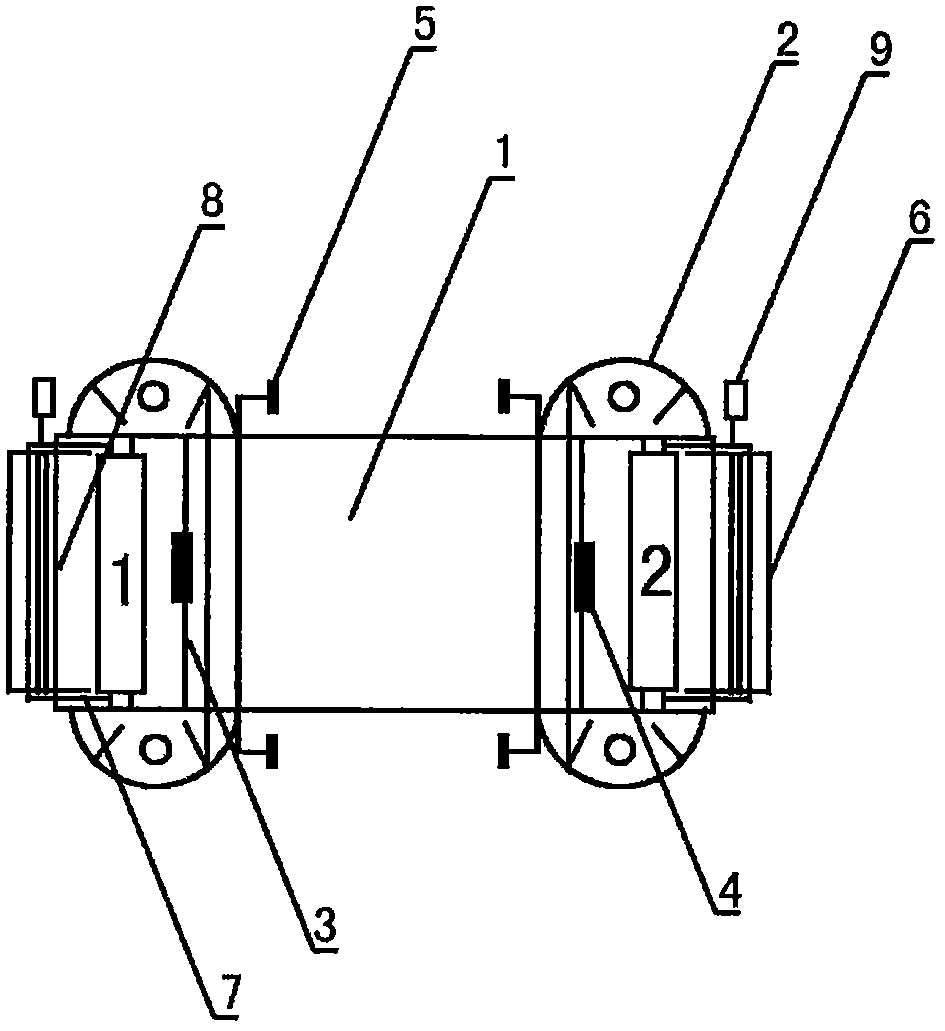

[0012] Embodiment: as shown in the accompanying drawing. Plastic wire drawing machine non-iron derusting assembly, including a wire drawing machine heating area (1), the non-iron protection components with structures such as rollers at both ends of the heating area (1), including a fan-shaped protective cover device (2), supporting rollers (3), temperature rise sensing device (4), linkage regulator (5), derusting device (6) is positioned at the outer end of the roller through telescopic support (7), and the middle part is equipped with a clearing device (8). After adjusting the positioning height of the support in the wire walking direction, the rust removal is carried out synchronously, and the protection work is carried out for the exposed roller at the same time.

[0013] The non-ironing derusting component of the plastic wire drawing machine is equipped with a prompting device (9), which sends a corresponding prompting message when the derusting operation is completed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com