Micro LED transfer apparatus and transfer method and manufacturing method of transfer apparatus

A technology of a transport device and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of increasing the manufacturing cost and process complexity of the transport device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] As mentioned in the background technology, the existing Micro LED transfer device controls the working state of the transfer unit through the micro switch connected to the transfer unit. Since each micro switch is a CMOS switch circuit, and the manufacturing process of the CMOS switch circuit Complicated, thus resulting in high manufacturing cost of the transfer device.

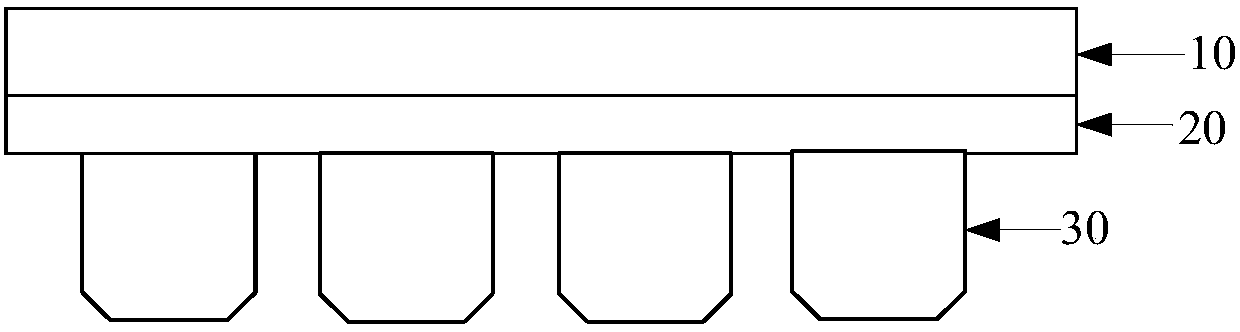

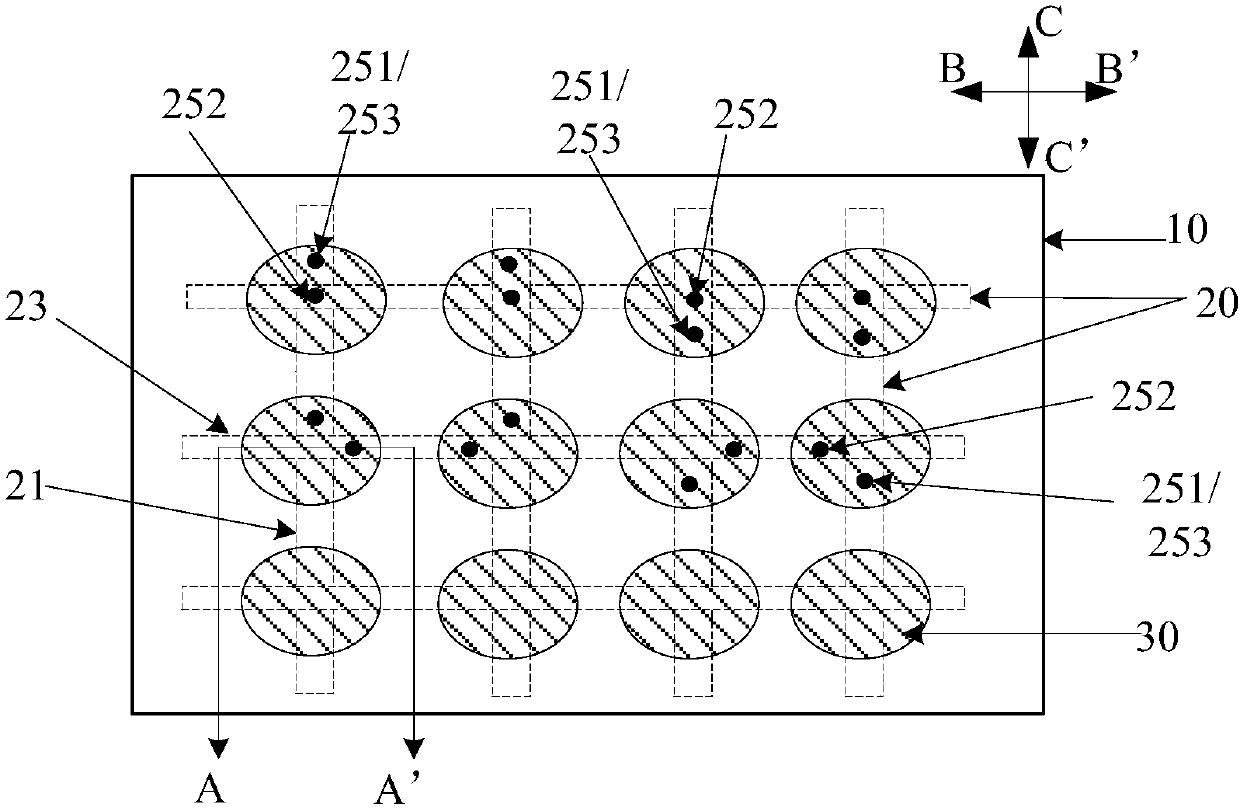

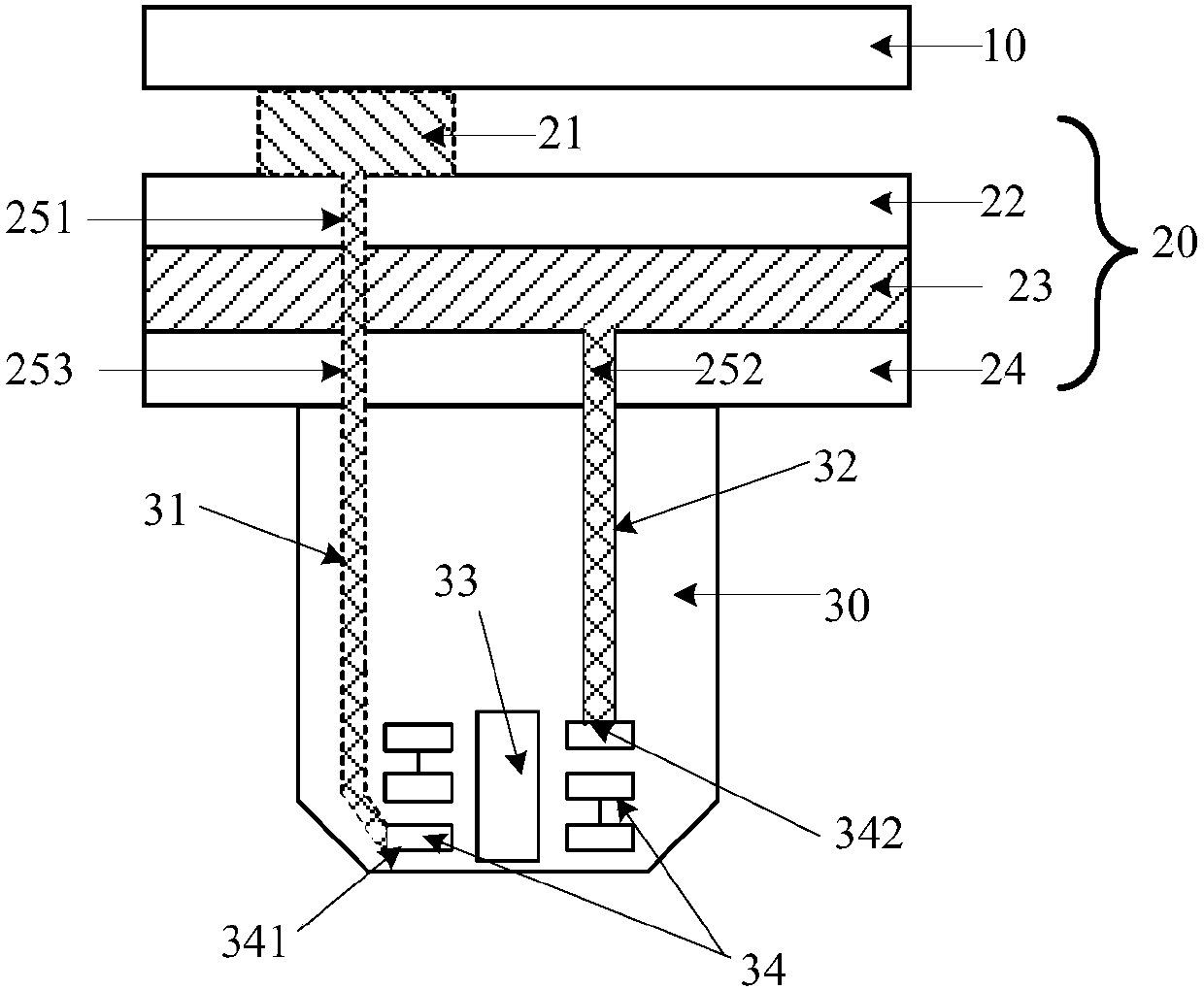

[0082] Based on this, the present invention provides a Micro LED transfer device, which reduces the manufacturing cost of the Micro LED transfer device compared with the prior art, such as figure 1 As shown, it is a cross-sectional view of the Micro LED transfer device. The transfer device includes: a transfer substrate 10, a drive electrode 20 located on the transfer substrate 10, and a drive electrode 20 located on the side away from the transfer substrate 10. A translocation unit array, the translocation unit array comprises a plurality of translocation units 30 .

[0083] Wherein, the driving elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com