Two-stage gas-liquid separation and recovery device for immersion type lithography machine

A technology of gas-liquid separation and recovery device, which is applied in the direction of exposure device, separation method, optical mechanical equipment, etc. of photo-plate making process, which can solve the problems of poor separation effect, large space occupation, and low separation efficiency, so as to ensure coordinated work Effects of effectiveness, efficiency and effectiveness enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

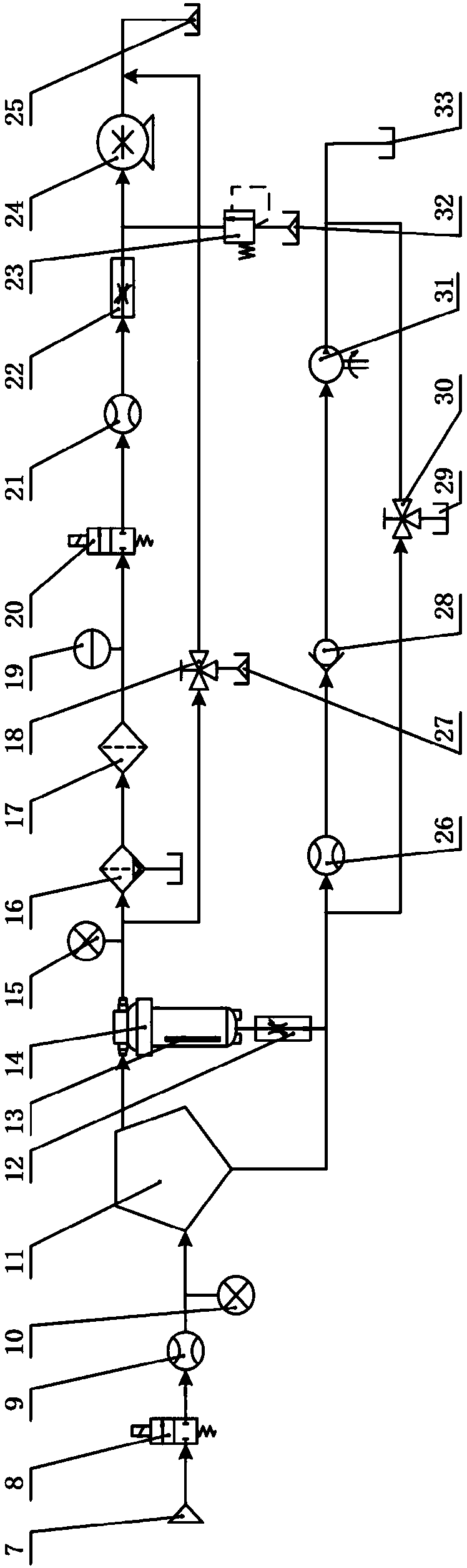

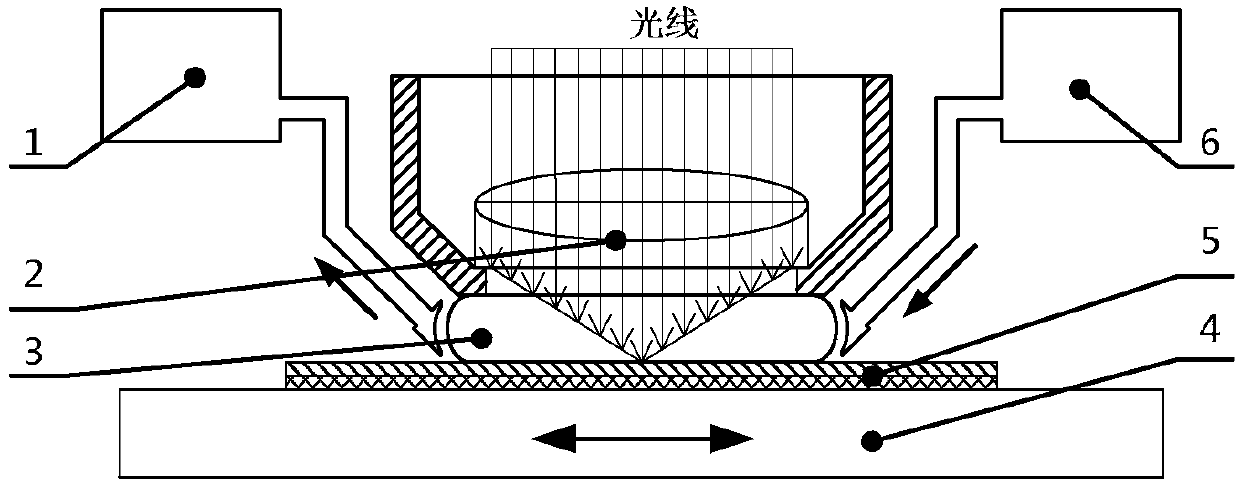

[0018] like figure 1 As shown, a two-stage gas-liquid separation and recovery device for an immersion lithography machine includes a gas-liquid separator 11 for gas-liquid separation using the centrifugal principle, and a gas-liquid separation device equipped with a liquid level gauge 13 to monitor liquid level changes Tank 14, liquid flow controller 12, two-phase flow circuit before gas and liquid separation, exhaust circuit after gas and liquid separation, drain circuit after gas and liquid separation; the upper inlet of gas-liquid separator 11 is connected with gas and liquid The two-phase flow circuit before liquid separation is connected, the upper outlet of the gas-liquid separator 11 is connected with the upper inlet of the gas-liquid separation tank 14, and the upper outlet of the gas-liquid separation tank 14 is connected with the exhaust circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com