Anti-bending fixture and design method for single-lap riveted joints

A technology of single-lap joints and design methods, which is applied in the testing of machines/structural components, testing of mechanical components, instruments, etc., can solve problems such as bending and deformation of single-lap riveting joints, great influence on test results, and not being on the same plane , to achieve the effect of improving the neutrality of clamping, simple and firm structure, and preventing excessive bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

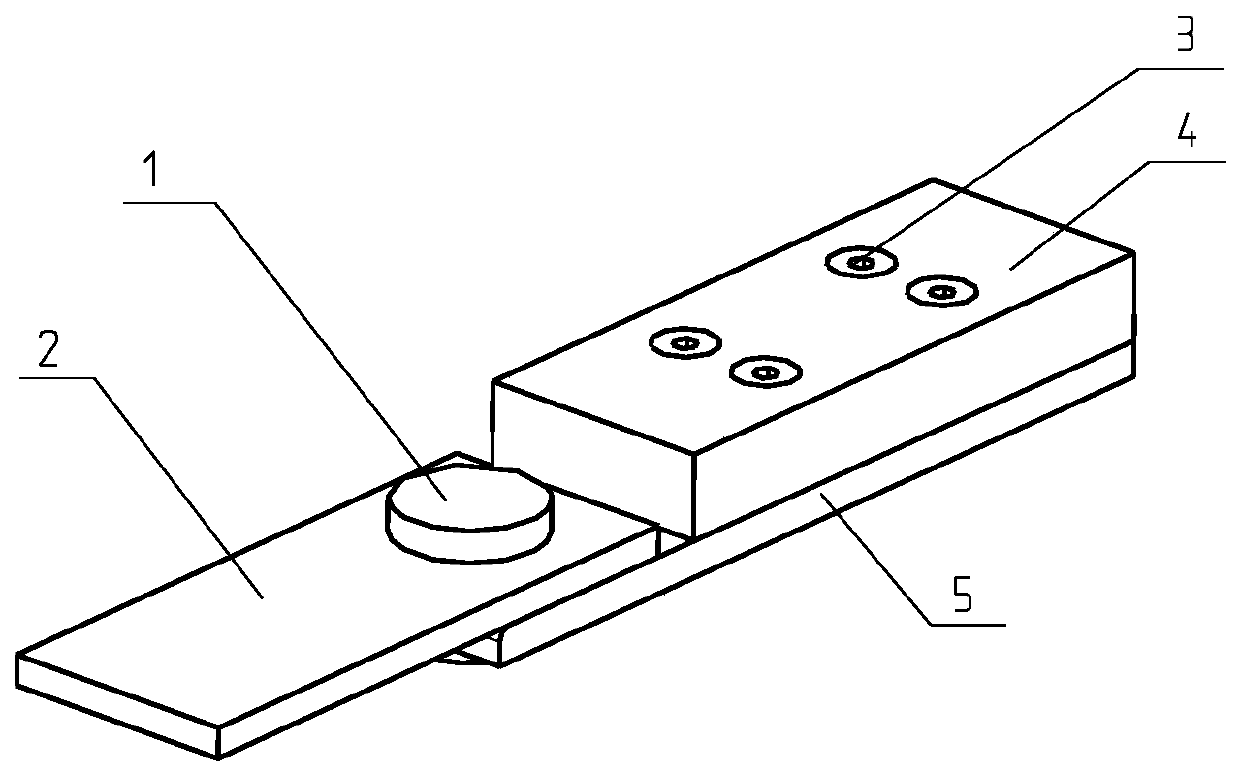

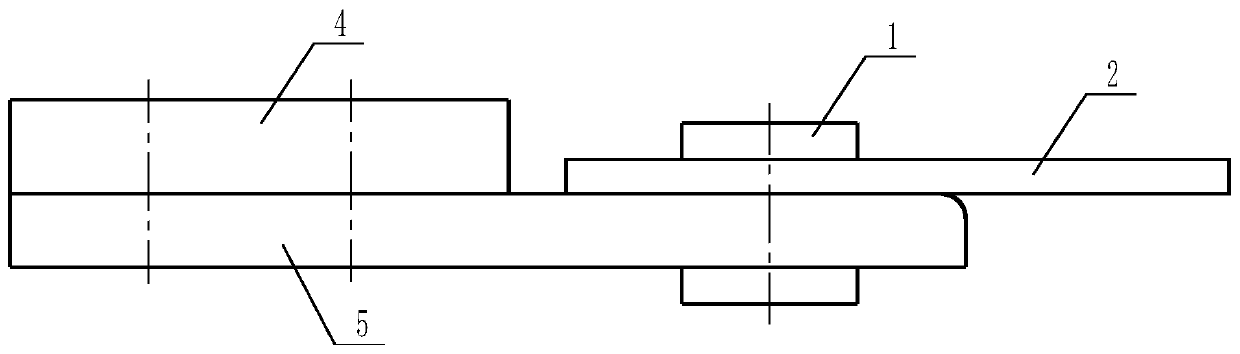

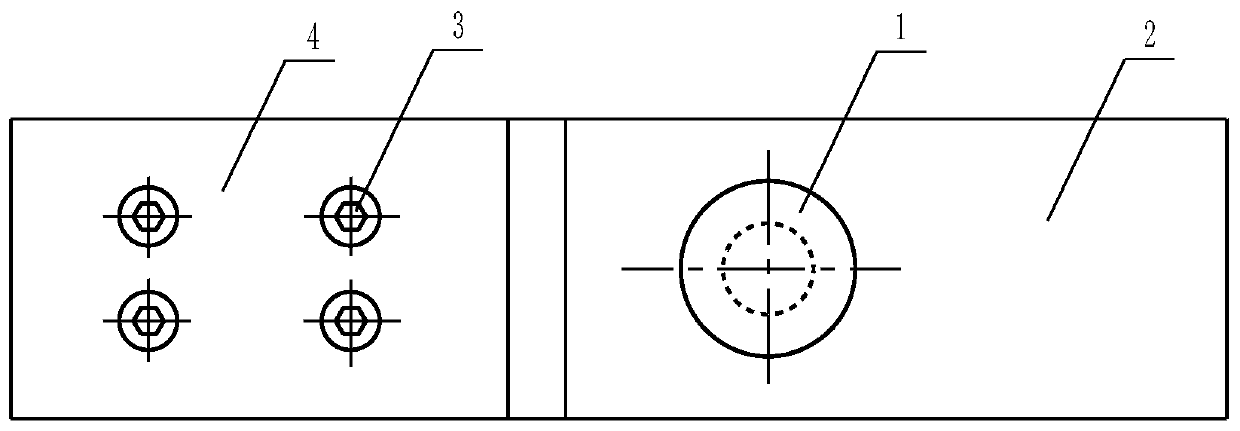

[0058] An anti-bending fixture for a single-lap riveted joint, the innovation of which is that it includes an upper splint 4, a lower splint 5, and a single-lap joint test piece 2, and the lower splint 5 includes a first splint section at the fixed end and a second splint section at the riveted end , the corresponding positions of the single lap joint test piece and the second splint section of the lower splint are provided with rivet mounting holes 6, and the rivets 1 pass through the rivet mounting holes to rivet and fix the single lap joint test piece and the second splint section of the riveted end of the lower splint, The upper splint and the first splint section of the lower splint are fixed by countersunk screws 3, the length of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com