Preparation method of ultrahigh molecular weight polyethylene fiber having super coarse denier silk, and ultrahigh molecular weight polyethylene fiber produced therethrough

A technology of ultra-high molecular weight and polyethylene fiber, which is applied in the direction of dry spinning and single-component polyolefin rayon, can solve the problem that the output cannot meet the market demand, and achieve the purpose of increasing denier, reducing production cost, and reducing Effect of Extraction Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

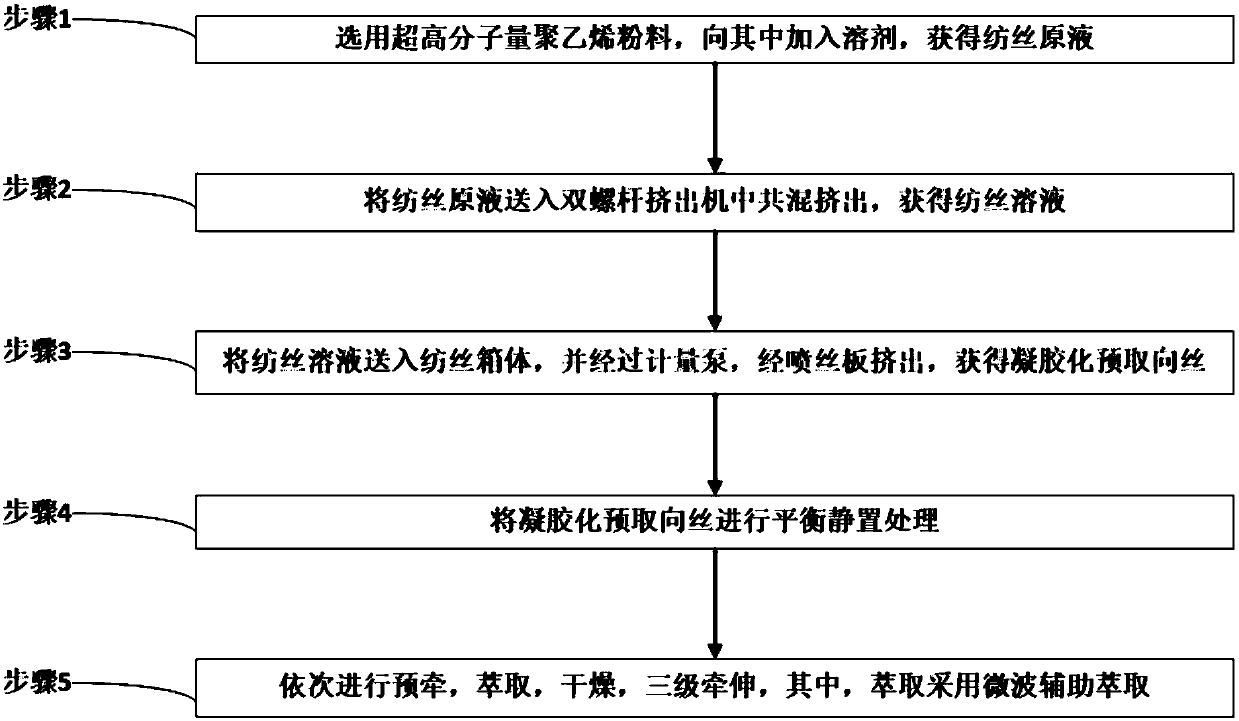

[0027] figure 1 A flow chart of a method for preparing an ultra-high molecular weight polyethylene fiber with ultra-coarse denier filaments provided in an embodiment of the present invention is shown. see figure 1 , the preparation method of the ultra-high molecular weight polyethylene fiber with ultra-thick denier silk according to the embodiment of the present invention comprises the following steps:

[0028] Step 1, select ultra-high molecular weight polyethylene powder, add solvent oil to it, and obtain spinning stock solution;

[0029] Step 2, sending the spinning dope into a twin-screw extruder for blending and extrusion to obtain a spinning solution;

[0030] Step 3, feeding the spinning solution into the spinning box, and extruding it through a spinneret through a metering pump to obtain gelled pre-oriented filaments;

[0031] Step 4, carrying out equilibrium static treatment on the gelatinized pre-oriented yarn;

[0032] Step 5. Pre-drawing, extracting, drying, an...

Embodiment 1

[0048] 1. Select ultra-high molecular weight polyethylene powder with a weight-average molecular weight of 5 million, add No. 68 white oil to it, wherein the mass ratio of No. 68 white oil and ultra-high molecular weight polyethylene powder is 1:4, to obtain spinning. silk stock solution;

[0049] 2. The spinning stock solution is sent to a twin-screw extruder for blending and extrusion to obtain a spinning solution;

[0050] 3. The spinning solution is fed into the spinning box, and extruded through a spinneret through a metering pump to obtain gelled pre-oriented filaments;

[0051] 4. The gelation pre-oriented yarn is subjected to a water bath cooling equilibrium treatment;

[0052] 5. Pre-drawing, extracting, drying, and tertiary drawing are performed on the gelatinized pre-oriented yarn after the static treatment in sequence, wherein the extraction adopts microwave-assisted extraction, and the drying air volume is 30,000 m 3 / h, the third-stage drafting temperature is 1...

Embodiment 2

[0054] 1. Select ultra-high molecular weight polyethylene powder with a weight-average molecular weight of 4.5 million, add No. 64 white oil to it, wherein the mass ratio of No. 64 white oil and ultra-high molecular weight polyethylene powder is 1:5 to obtain spinning. silk stock solution;

[0055] 2. The spinning stock solution is sent to a twin-screw extruder for blending and extrusion to obtain a spinning solution;

[0056] 3. The spinning solution is fed into the spinning box, and extruded through a spinneret through a metering pump to obtain gelled pre-oriented filaments;

[0057] 4. The gelation pre-oriented yarn is subjected to a water bath cooling equilibrium treatment;

[0058] 5. Pre-drawing, extracting, drying, and tertiary drawing are performed on the gelatinized pre-oriented yarn after the static treatment in sequence, wherein the extraction adopts microwave-assisted extraction, and the drying air volume is 29000 m 3 / h, the third-stage drafting temperature was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com