Electrochemical method for preparing mesoporous tungsten trioxide film

A tungsten trioxide, electrochemical technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., to achieve the effect of large specific surface area, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Cut the tungsten sheet with a thickness of 0.8mm into 1×1cm 2 The specifications were ultrasonically cleaned in acetone, ethanol and deionized water for 15 minutes, rinsed with deionized water and dried to obtain a metal tungsten electrode after degreasing; the ionic liquid 1-ethyl-3 methylimidazolium tetrafluoroboron Salt ([EMim]BF 4 ) 0.6mL and 9mL of deionized water were added to 51mL of ethylene glycol, wherein the volume fraction of ionic liquid was 1%, and the volume fraction of deionized water was 15%. Use tungsten sheet as anode, titanium sheet (thickness 0.2mm, specification 2×2cm 2 ) as the cathode, put it into the electrolyte, keep the electrode distance at 1.5cm, control the temperature of the electrolyte at 25°C, and oxidize at 10V for 3h; rinse the oxidized metal tungsten sheet with deionized water, and dry it.

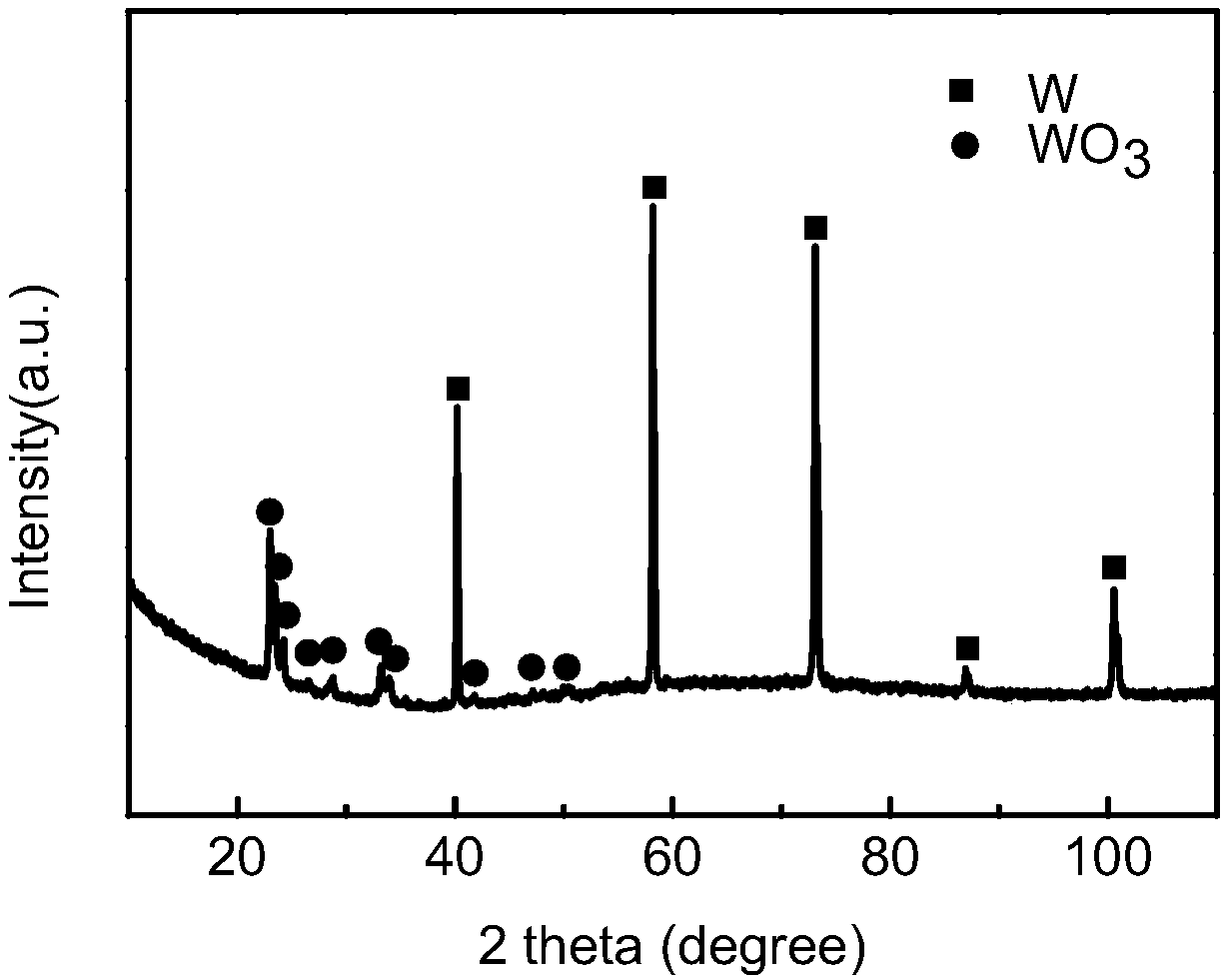

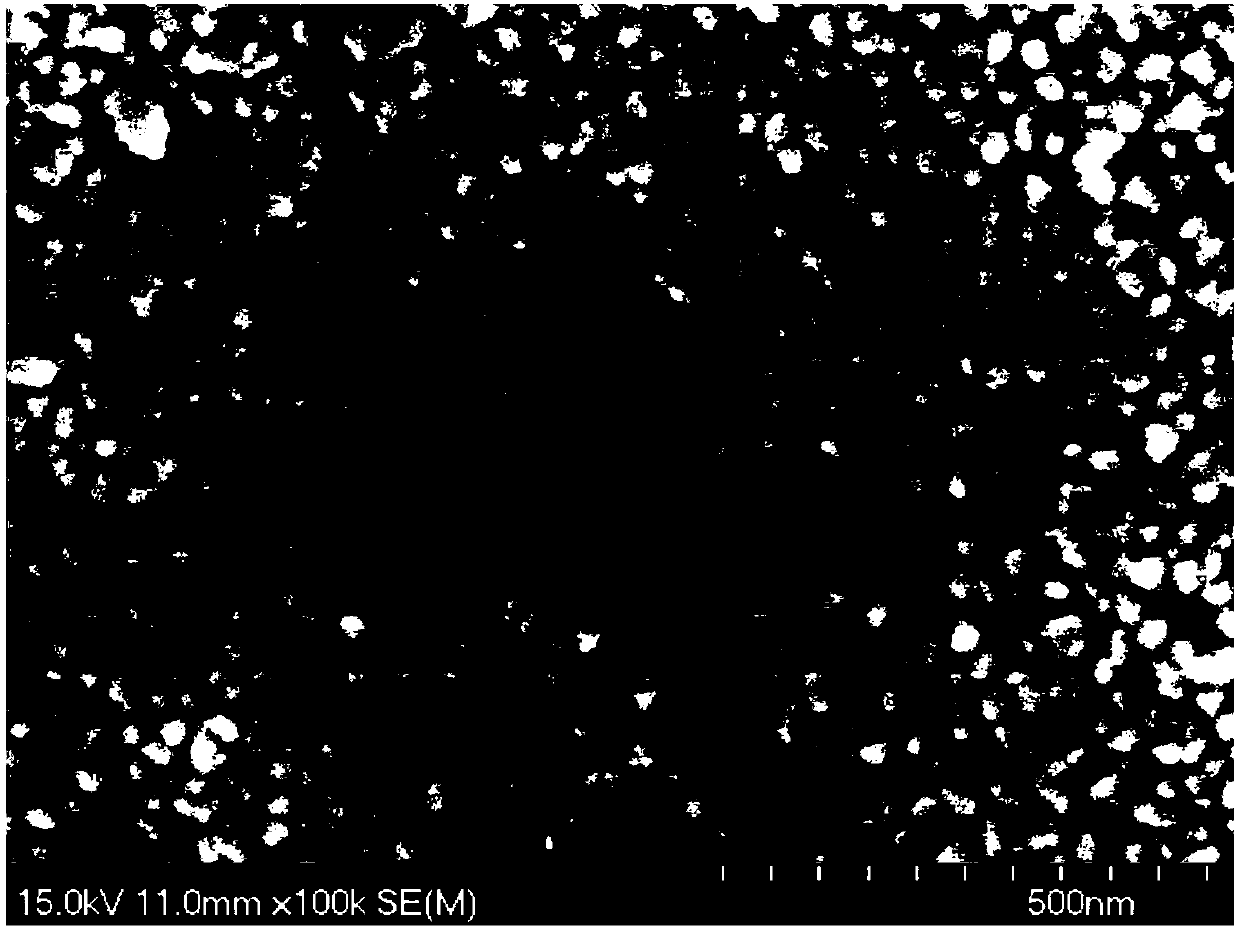

[0031] The phase composition of the prepared mesoporous tungsten trioxide thin film is as follows: figure 1 It can be seen from the scanning e...

Embodiment 2

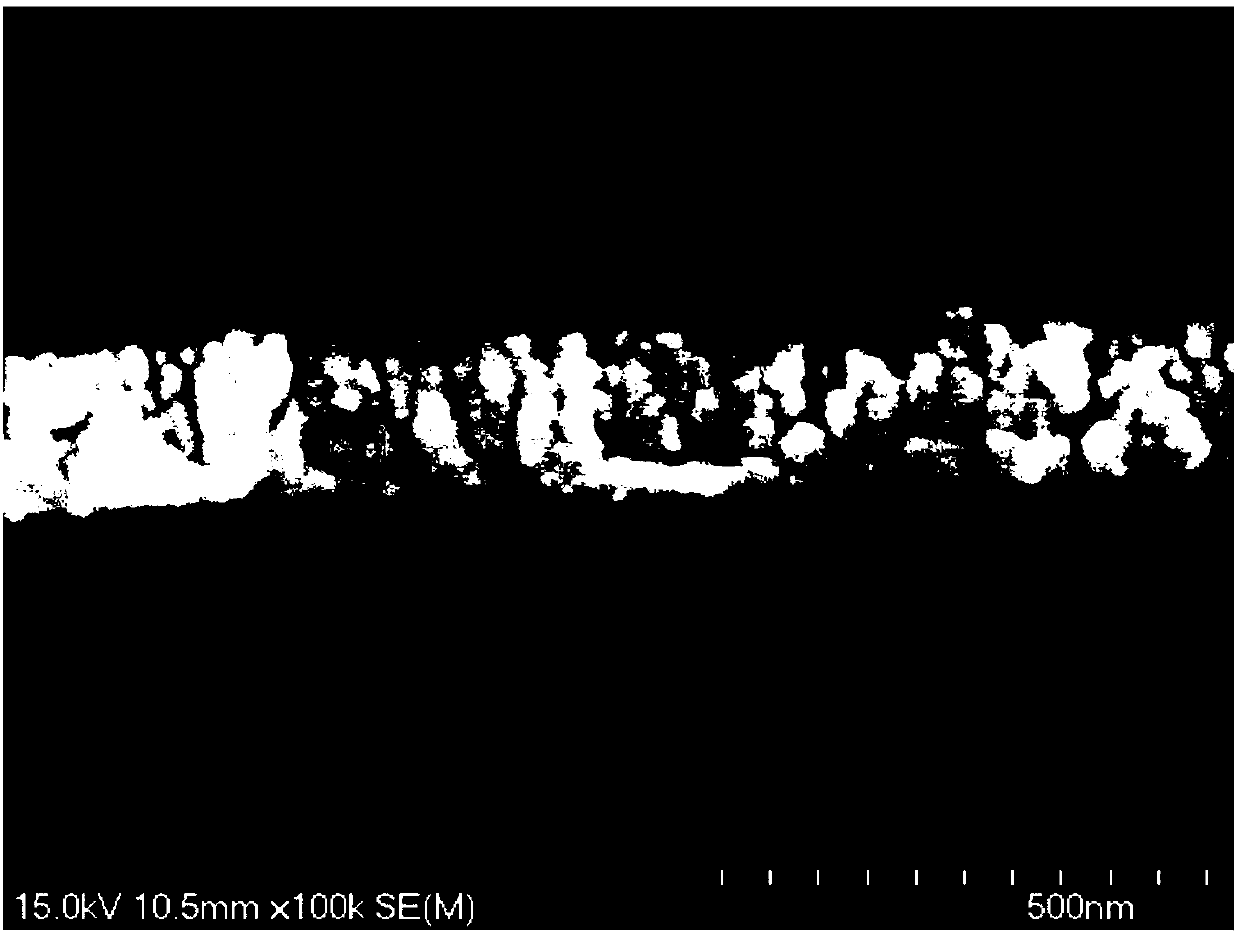

[0033] Cut the tungsten sheet with a thickness of 0.8mm into 1×1cm 2 The specifications were ultrasonically cleaned in acetone, ethanol and deionized water for 15 minutes, rinsed with deionized water and dried to obtain a metal tungsten electrode after degreasing; the ionic liquid 1-ethyl-3 methylimidazolium tetrafluoroboron Salt ([EMim]BF 4 ) 0.6mL and 9mL of deionized water were added to 51mL of ethylene glycol, wherein the volume fraction of ionic liquid was 1%, and the volume fraction of deionized water was 15%. Use tungsten sheet as anode, titanium sheet (thickness 0.2mm, specification 2×2cm 2 ) as the cathode, put it into the electrolyte, keep the distance between the electrodes at 1.5cm, control the temperature of the electrolyte at 25°C, and oxidize it at a voltage of 10V for 1h; wash the oxidized metal tungsten sheet with deionized water, and dry it to obtain Mesoporous tungsten trioxide thin films, such as Figure 4 shown.

Embodiment 3

[0035] Cut the tungsten sheet with a thickness of 0.8mm into 1×1cm 2 The specifications were ultrasonically cleaned in acetone, ethanol and deionized water for 15 minutes, rinsed with deionized water and dried to obtain a metal tungsten electrode after degreasing; the ionic liquid 1-ethyl-3 methylimidazolium tetrafluoroboron Salt ([EMim]BF 4 ) 0.6mL and 9mL of deionized water were added to 51mL of ethylene glycol, wherein the volume fraction of ionic liquid was 1%, and the volume fraction of deionized water was 15%. Use tungsten sheet as anode, titanium sheet (thickness 0.2mm, specification 2×2cm 2 ) as the cathode, put it into the electrolyte, keep the distance between the electrodes at 1.5cm, control the temperature of the electrolyte at 25°C, and oxidize it at a voltage of 10V for 7h; rinse the oxidized metal tungsten sheet with deionized water, and dry it to obtain Mesoporous tungsten trioxide thin films, such as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com