Preparation method of rosa roxburghii fruit vinegar

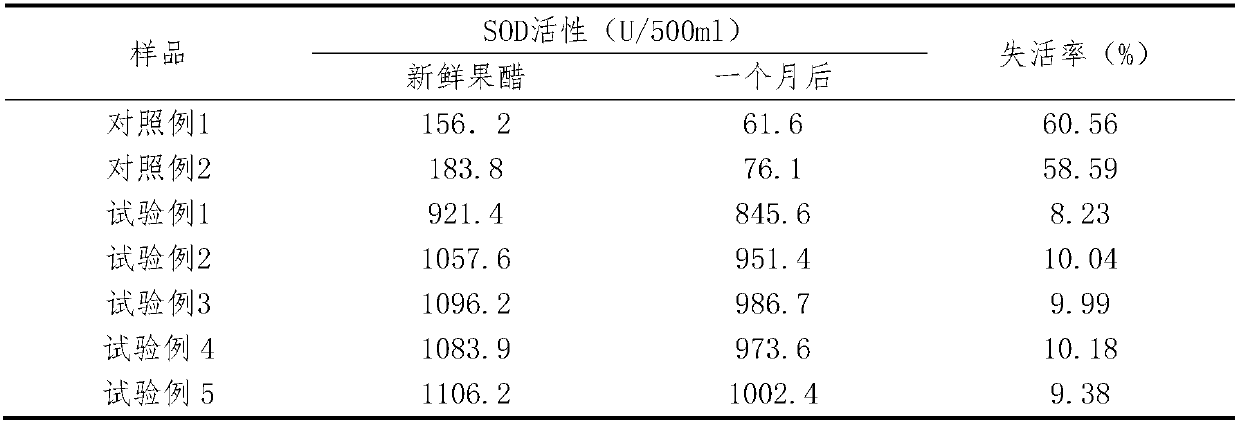

A technique for prickly pear fruit and prickly pear is applied in the field of preparation of prickly pear fruit vinegar, which can solve the problems of unstable chemical properties, easy oxidation loss, influence on taste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of Rosa roxburghii vinegar, comprising the following steps:

[0027] A. Weigh qualified Rosa roxburghii and apples and wash them with clear water;

[0028] B. Appropriately crush all the above-mentioned washed raw materials, press to extract juice, or first press to prepare pure thorn pear juice, decoct to extract apple juice, and then extract the extracted pure thorn pear juice obtained by pressing and decocted apple Juice merged;

[0029] C. Add 0.001 pectinase to the mixed fruit juice for enzymolysis; the enzymolysis temperature is 30°C, and the enzymolysis time is 3h;

[0030] D. Ultra-high temperature sterilization: the mixed fruit juice after enzymolysis is sterilized by an ultra-high temperature sterilizer, the feed temperature is 120°C, and the discharge temperature is 40°C to obtain a feed liquid;

[0031] E. Alcoholic fermentation: add 0.1% dry yeast and 5% glucose to the feed liquid, stir evenly, and ferment for 10 days to obtain an alc...

Embodiment 2

[0038] A preparation method of Rosa roxburghii vinegar, comprising the following steps:

[0039] A. Weigh qualified Rosa roxburghii, hawthorn and grapes, and wash them with clear water;

[0040] B. Properly crush all the above-mentioned washed raw materials, press to extract juice, or first press to prepare pure thorn pear juice, decoct to extract the juice of hawthorn and grape, and then extract the pure thorn pear juice obtained by pressing and the decocted hawthorn , the extraction juice of grapes is merged;

[0041] C. Add 0.001% cellulase mixture to the mixed fruit juice for enzymolysis; the enzymolysis temperature is 35°C, and the enzymolysis time is 4h;

[0042] D. Ultra-high temperature sterilization: the mixed fruit juice after enzymolysis is sterilized by an ultra-high temperature sterilizer, the feed temperature is 130°C, and the discharge temperature is 50°C to obtain a feed liquid;

[0043] E. Alcoholic fermentation: add 0.5% dry yeast and 10% glucose to the fee...

Embodiment 3

[0050] A preparation method of Rosa roxburghii vinegar, comprising the following steps:

[0051] A. Take qualified Rosa roxburghii, persimmons, pears and apricots, and wash them with clear water;

[0052] B. Appropriately crush all the above-mentioned washed raw materials, squeeze to extract juice, or first squeeze to prepare pure Rosa roxburghii juice, decoct to extract the juice of persimmon, pear, apricot, and then decoct the pure Rosa roxburghii juice obtained by squeezing to obtain The extracted juices of persimmon, pear and apricot are combined;

[0053]C. Adding a mixture of 0.01% pectinase and 0.05% cellulase to the mixed fruit juice for enzymolysis; the enzymolysis temperature is 50°C, and the enzymolysis time is 4h;

[0054] D. Ultra-high temperature sterilization: the mixed fruit juice after enzymolysis is sterilized by an ultra-high temperature sterilizer, the feed temperature is 130°C, and the discharge temperature is 55°C to obtain a feed liquid;

[0055] E. Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com