Automatic capping device for outer wall coating barrel

An exterior wall coating, automatic technology, applied in the direction of flange type bottle caps, etc., can solve the problem of insufficient sealing of barrel caps, and achieve the effects of improving sealing, reducing distance, and widening the range of turning angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

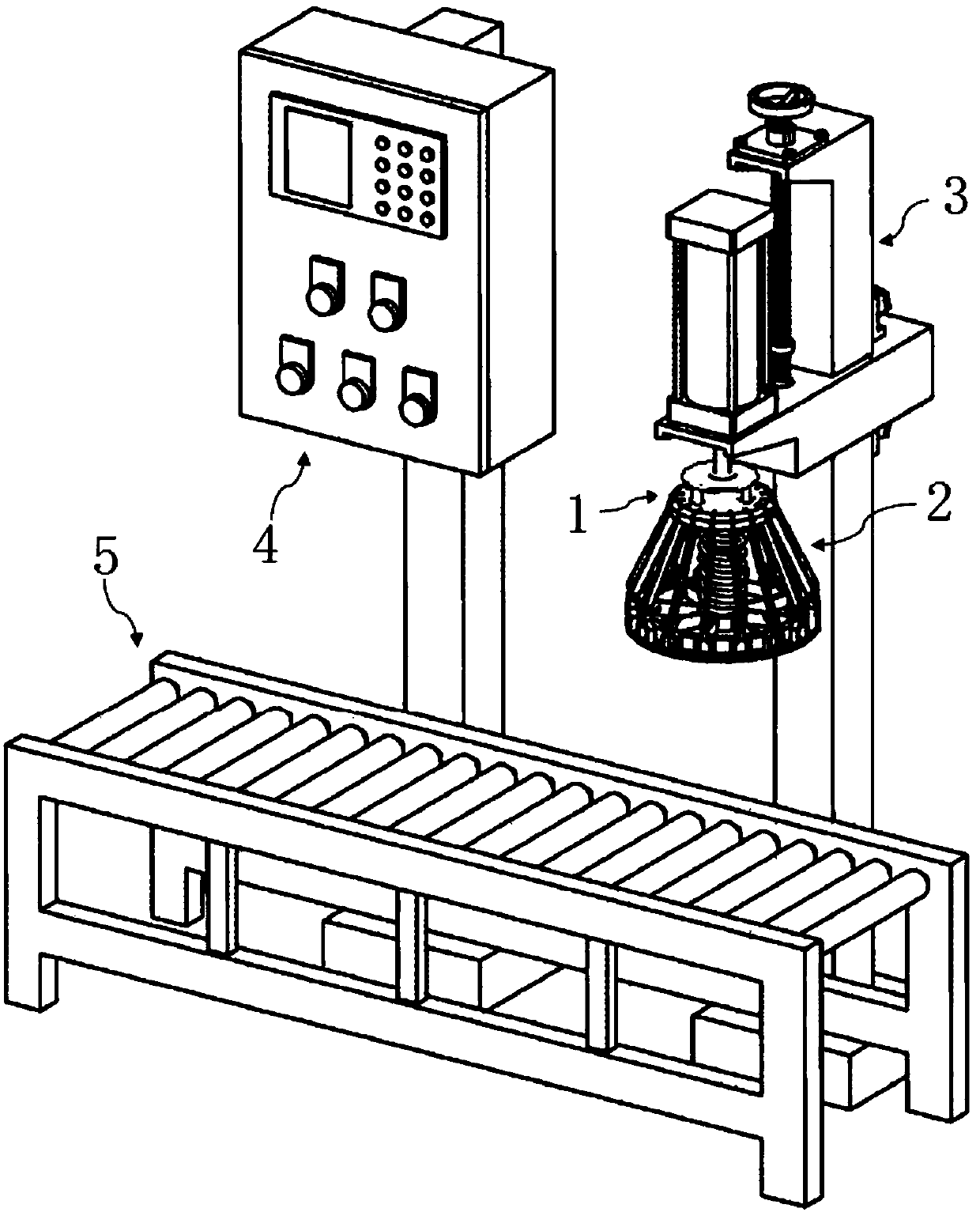

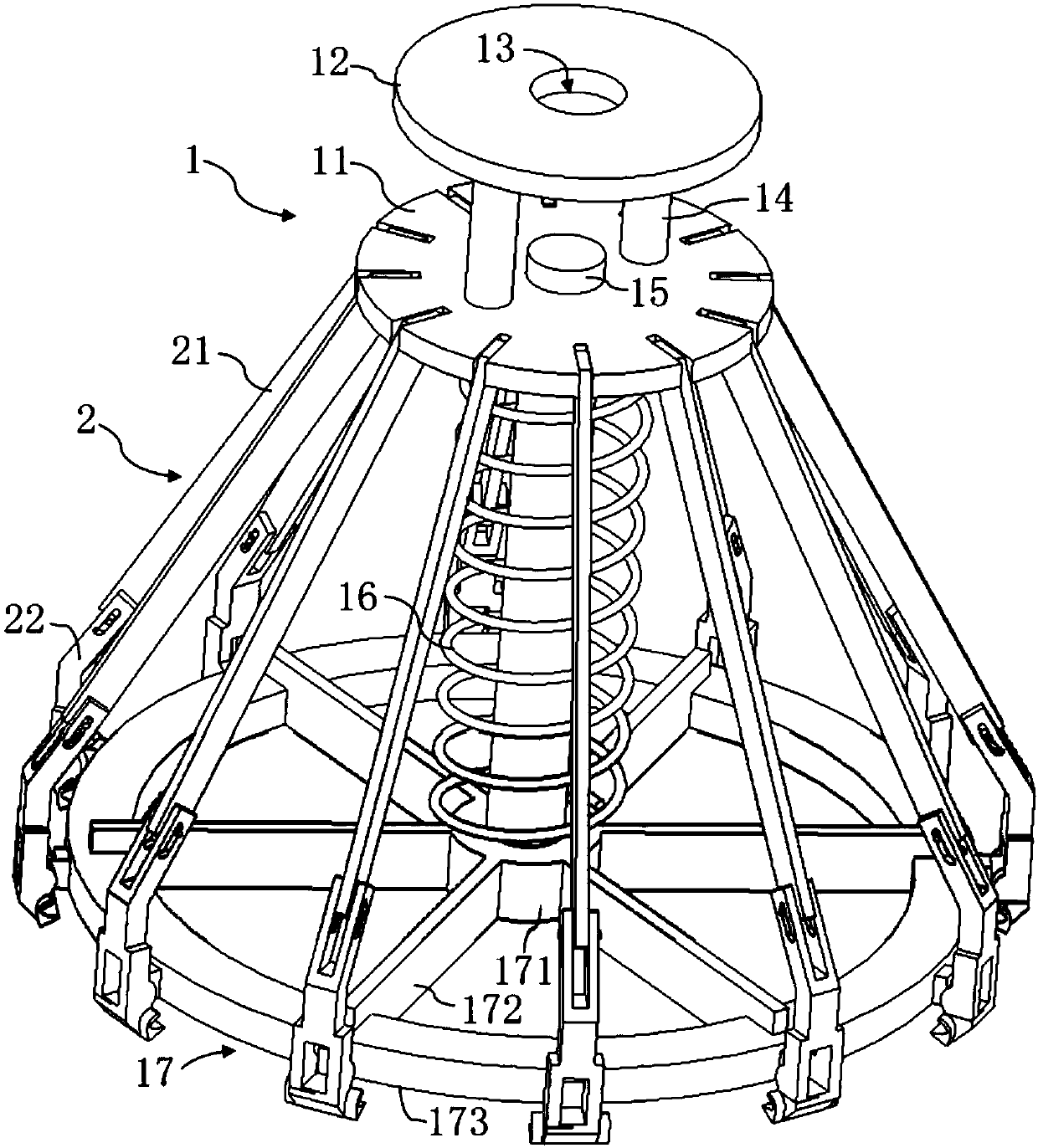

[0033] combine figure 1 , figure 2 , the present embodiment provides an automatic capping device for exterior wall paint barrels, including a transport platform 5, a support frame 3 and a press-fitting mechanism, and the transport platform 5 is provided with rollers to facilitate the transfer and support of the barrel body. The frame 3 is attached to the transport platform 5, and a cylinder is vertically installed on the support frame 3, and the piston shaft of the cylinder is connected with a press-fitting mechanism; the piston shaft can drive the press-fitting mechanism to compress and seal the barrel cover onto the barrel . Further, an automatic baffle can be set on the transport table 5 for positioning the barrel so that it is automatically positioned under the press-fitting mechanism. This automatic baffle plate can be the baffle plate hinged on the transport platform 5, and is driven by a motor, and can be controlled to automatically swing onto the transport platform ...

Embodiment 2

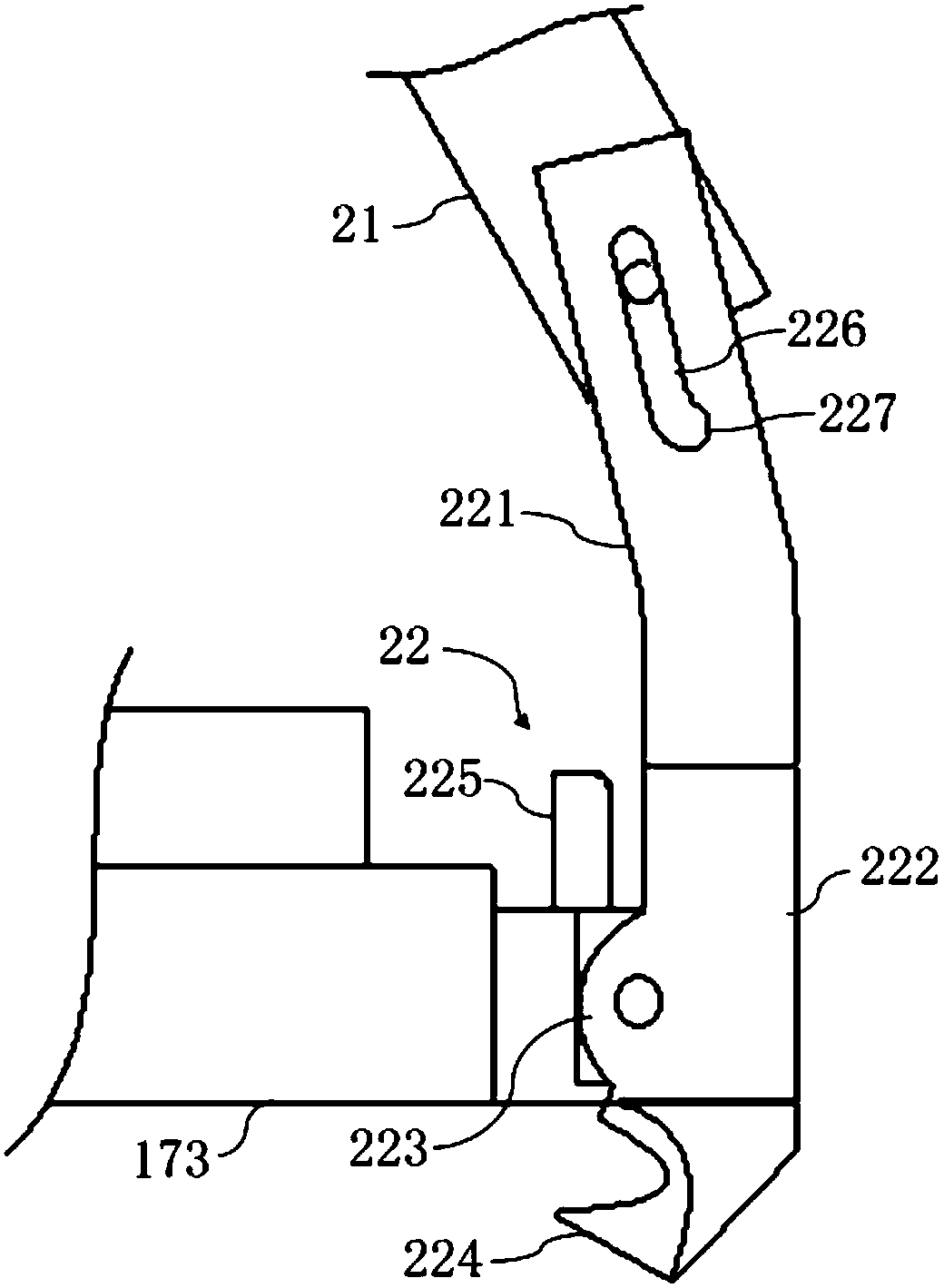

[0040] An automatic capping device for exterior wall paint buckets in this embodiment has the same basic structure as in Embodiment 1, and further: in this embodiment, the size of the pin shaft matches the size of the chute 226, and there is a gap between the two. The gap can be controlled within 1.5mm. More optimally, it can be controlled within 1 mm, for example, 0.5 mm. Due to the small clearance, on the one hand, it will not affect the sliding of the pin shaft, and on the other hand, it will not cause the pin shaft to shake greatly. If the gap is too large, when the upper end of the transmission arm 21 travels a certain distance, the angle of rotation cannot be fully reflected on the pressing claw 22, which will result in insufficient accuracy and affect the press-fit sealing effect.

[0041] In addition, it is worth noting that when the pin shaft slides in the chute 226, the chute 226 and the transmission arm 21 are always in a non-parallel state. When the pin shaft is at...

Embodiment 3

[0043] An automatic capping device for exterior wall paint barrels in this embodiment has the same basic structure as that of Embodiment 2, and further: the lower claw arm 222 protrudes from the side wall and is provided with an auricle plate 223, the auricle The plate 223 is a protruding arc structure, and a hole is opened on the auricle plate 223 for installing the hinge shaft.

[0044] Through the setting of the chute, although the distance between the two relative sealing heads 224 can be reduced, the distance that can be shortened is limited. In order to install the hinge shaft, the lower end of the pinna plate 223 is connected to the sealing head 224, and the pressure groove 2242 opened on the sealing head 224 is used to seal the cover plate. This structure can further shorten the distance between the sealing head 224 and the hinge shaft , the moment arm is reduced, and then the distance between the hinge shafts on the two opposite pressing jaws 22 can be shortened again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com