Nylon rope ring forming machine

A molding machine and rope loop technology, which is applied to household components, household appliances, and other household appliances, can solve the problems of low efficiency, high labor intensity of workers, and low production efficiency, and achieve simple operation, simple structure, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to have a clearer understanding of the technical features, purposes, effects and embodiments of the present invention, specific implementations of the present invention will now be described in conjunction with the accompanying drawings.

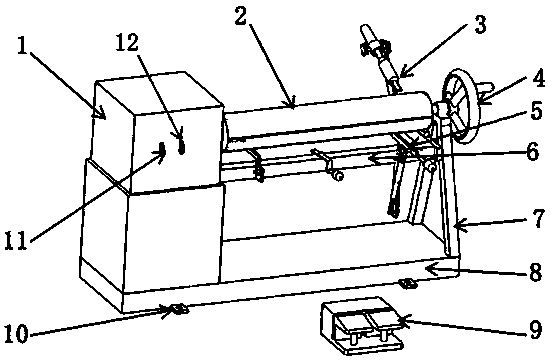

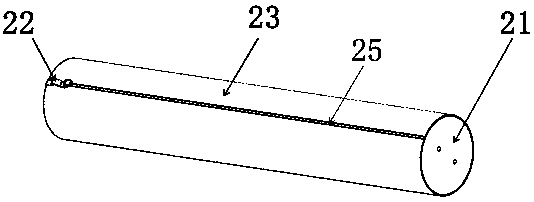

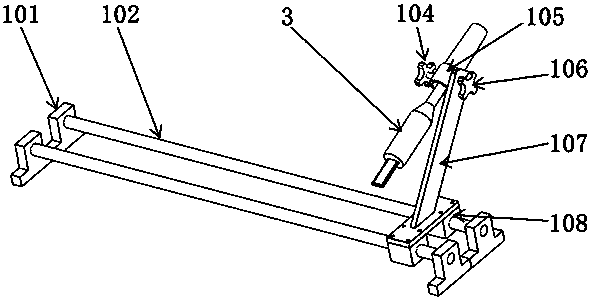

[0039] Such as Figure 1-4 As shown, the nylon loop forming machine includes a bedside box 1, a roller 2, an electric soldering iron 3, a hand wheel 4, a rope pressing mechanism 5, a beam 6, a tripod 7, a machine chassis 8, a foot switch 9 and a rail mechanism , bedside box 1 and tripod 7 are respectively arranged at the left and right ends of machine tool chassis 8, and geared motor is installed in the upper part of bedside box 1, and speed control switch 11 and switch 12 are set outside bedside box 1, and hand is set on the support seat of tripod 7 tops. Wheel 4, handwheel 4 rotating shafts are threadedly connected with the support seat, and headstock 1 and tripod 7 are connected by crossbeam 6, and crossbeam 6 is an angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com