Nanofiltration membrane process system for deep recovery of waste alkaline liquor

A process system and nanofiltration membrane technology, which is applied in the field of waste liquid treatment in the industry, can solve problems such as the inability to fundamentally improve the efficiency of waste lye recovery and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

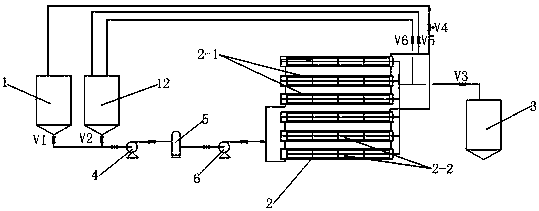

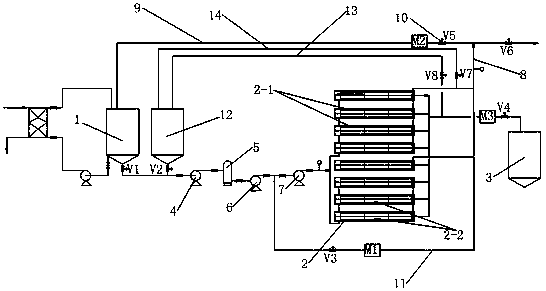

[0021] This embodiment proposes a nanofiltration membrane process system for deep recovery of waste caustic soda, the nanofiltration membrane process system includes waste liquid tank 1, cleaning tank 12, nanofiltration membrane device 2, filtrate tank 3 and other equipment. Such as figure 2 As shown in the structure, it can be known that the waste liquid tank 1 is used to collect and store viscose waste caustic lye, and the waste liquid tank 1 is provided with a heating device or a heat exchange jacket for exchanging heat for the waste lye, and the nanofiltration membrane device 2 Connect to the waste liquid tank 1, the pipeline between the waste liquid tank 1 and the nanofiltration membrane device 2 is provided with a material pump 4, a security filter 5, a high pressure pump 6 and a circulation pump 7 in sequence, and the filtrate tank 3 is connected to the nanofiltration membrane The clear liquid outlet of the device 2, the concentrated liquid outlet of the nanofiltration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com