Flux cored wire for gas shielded arc welding

A gas shielded and arc welding technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the problems of high impact performance temperature, low welding metal grade, difficult structural material performance, etc., to achieve anti-corrosion Excellent hot crack resistance, excellent welding workability, and the effect of less diffusible hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

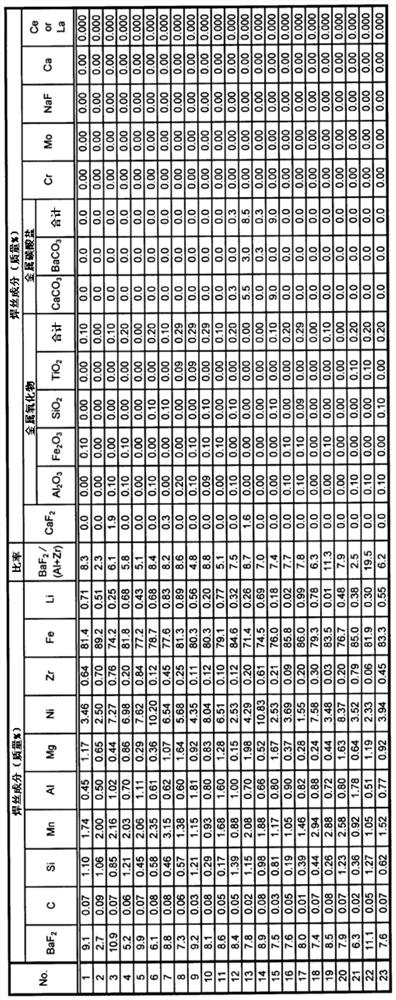

Image

Examples

Embodiment Construction

[0030] Hereinafter, the form for carrying out this invention is demonstrated in detail.

[0031] The gas-shielded arc welding flux-cored wire of this embodiment (hereinafter, appropriately referred to as "welding wire" or "flux-cored wire") is a wire used in gas-shielded arc welding, and is a wire in which a steel sheath is filled with flux.

[0032] Specifically, the welding wire according to the present embodiment is composed of a cylindrical steel sheath and flux filled inside the steel sheath. In addition, the welding wire may be of a seamless type without a seam on the steel sheath or a seam type with a seam on the steel sheath. In addition, the welding wire may or may not be plated on the surface (the outer side of the steel sheath).

[0033] In addition, the wire diameter (diameter) of the welding wire of this embodiment is not specifically limited, It just needs to be 1.2-2.4 mm. In addition, the flux filling rate of the welding wire is not particularly limited, but ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com