Cleaned briquette environment-friendly boiler

A clean and environmentally friendly technology, applied in the field of boilers, can solve problems such as energy waste and environmental pollution, and achieve the effect of solving the problem of smoke when the furnace is shut down.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

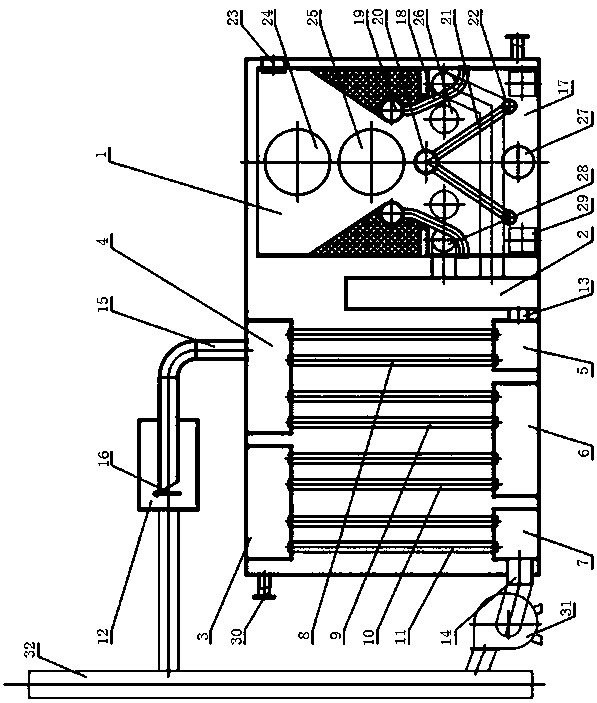

[0011] refer to figure 1 , the specific embodiment adopts the following technical solutions: clean type coal environmental protection boiler, including coal storage room 1, dust reduction room 2, the first upper smoke box 3, the second upper smoke box 4, the first lower smoke box 5-the third lower Smoke box 7, first return smoke pipe 8-fourth return smoke pipe 11, flue gas converter 12 and combustion chamber 17, coal storage chamber 1 is set on the upper part of combustion chamber 17, combustion chamber 17 is connected with dust reduction chamber 2 through pipes , the dust reduction chamber 2 is connected to the first lower smoke box 5 through the flue gas passage 13, the first lower smoke box 5 is connected to the second upper smoke box 4 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com