Lightweight fabricated staircase and construction method

A prefabricated and stair technology, applied in stairs, stepped structures, buildings, etc., can solve the problems of inability to realize prefabrication, low structural strength, and heavy weight, and achieve the goal of shortening building construction time, convenient and fast construction, and reducing weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

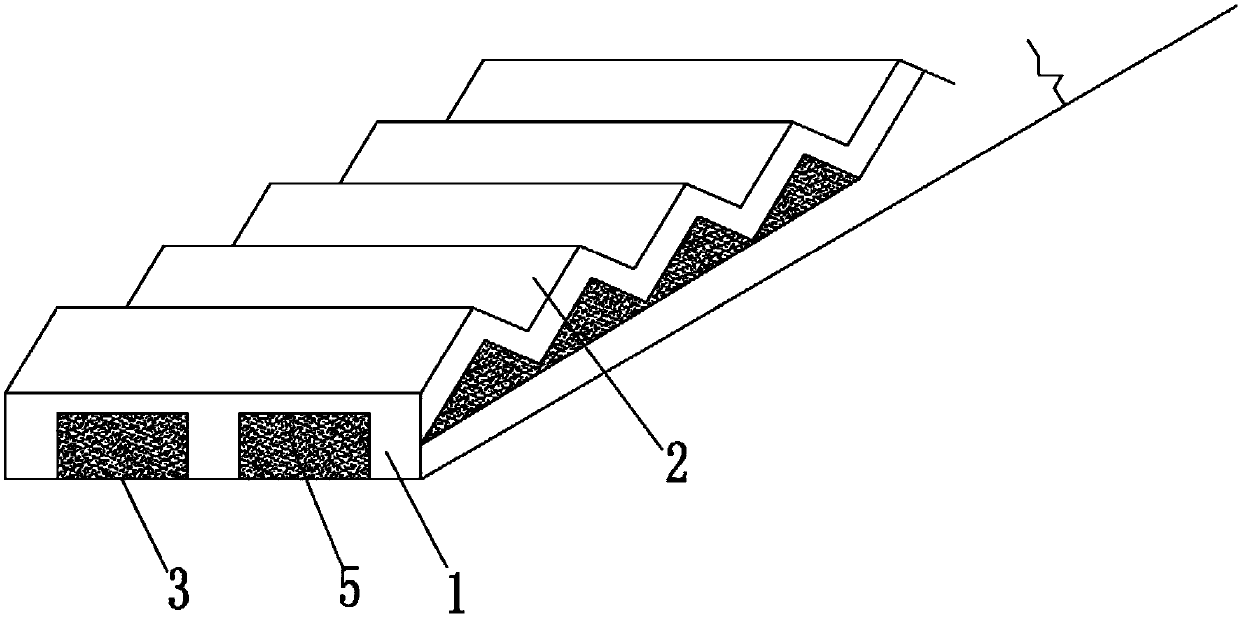

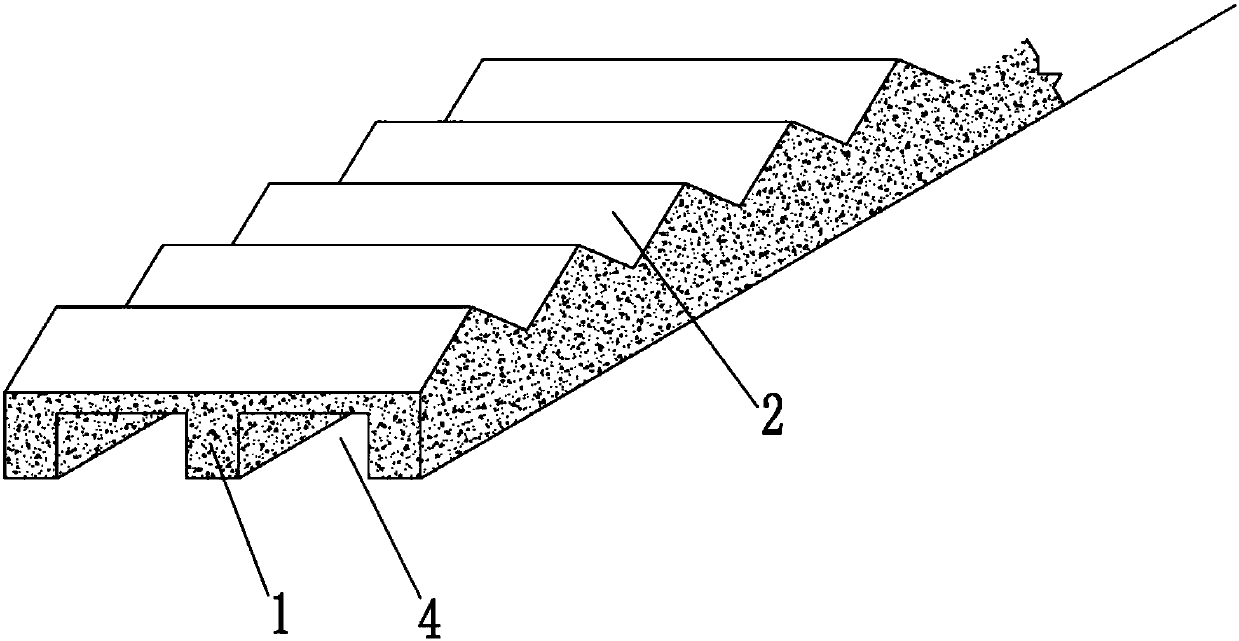

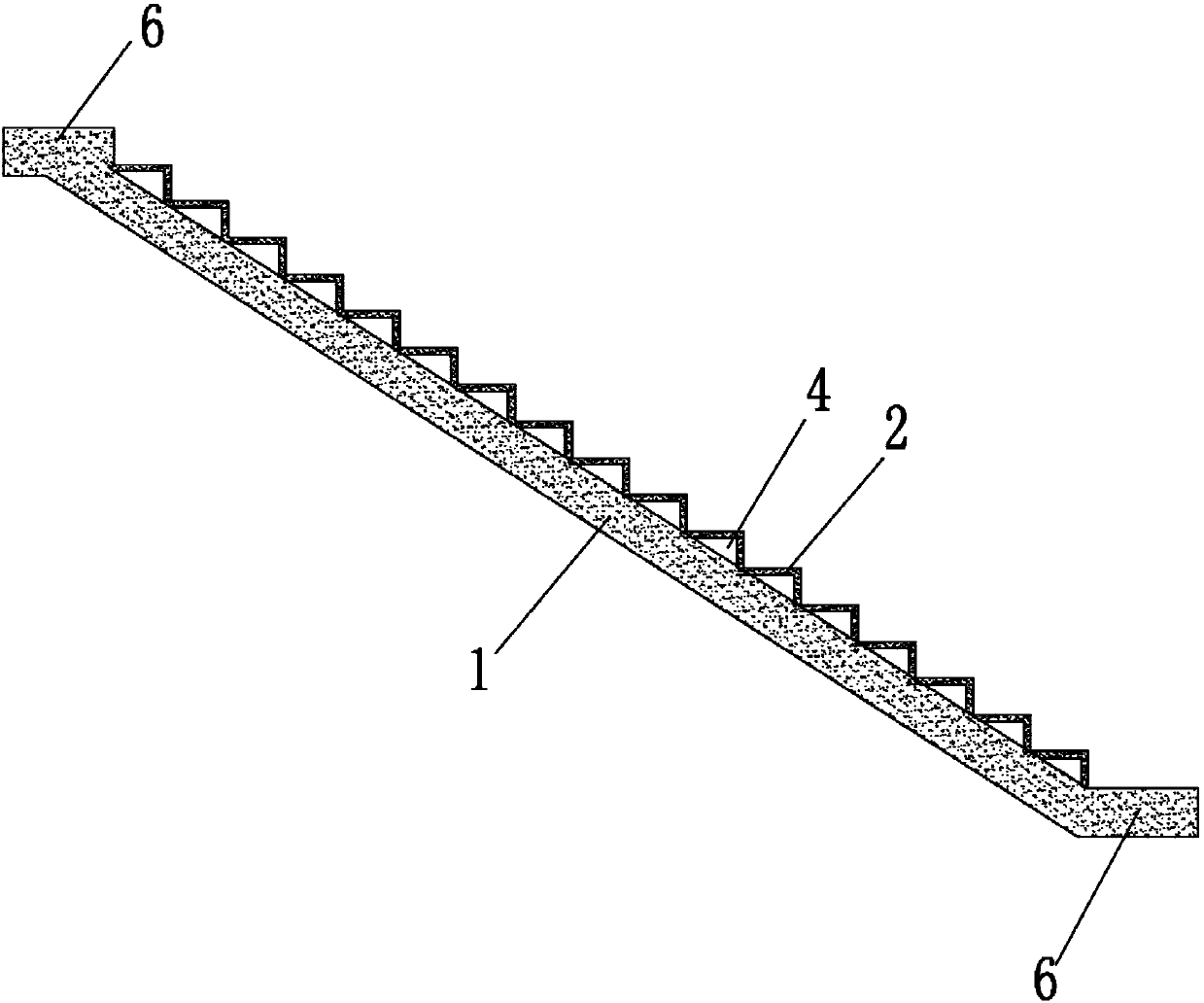

[0030] Please refer to the attached figure 1 to attach Figure 4 As shown, the present invention is a lightweight fabricated staircase, which includes at least two main body inclined beams 1 and at least two transverse structural beams 8 connecting the main body inclined beams 1 . In this embodiment, the main body slanting beam 1 is specifically provided with three lines, which are reinforced concrete prefabricated beams, which are inclined at 30-60°. Steps 6 are provided at both ends of the main body slanting beam 1 , and the main body slanting beam 1 and the steps 6 are integral prefabricated structures.

[0031] Several steps 2 are arranged on the main body slanting beam 1 . The steps 2 are prefabricated concrete steps, and the steel mesh 3 is used as the base form for pouring without dismantling, and the wall thickness thereof is 30-50 mm. Through the main oblique beam 1, the transverse structural beam 8, and the steps 2, an all-steel concrete structure "rectangular lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com