Washing machine with automatic leveling function

An automatic leveling and washing machine technology, which is applied in the field of washing machines, can solve the problems of heavy washing machine, self-heavy washing machine, washing machine damage, etc., and achieve the effect of reducing cost, simple and convenient installation method, and reducing the number of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Such as Figure 11 to Figure 16 As shown, a washing machine with automatic leveling function in this embodiment, the bottom of the washing machine is respectively equipped with fixed feet 1000 and hydraulic feet 800, at least two fixed feet 1000 and at least one hydraulic foot 800 are used to form It is used to support the support plane of the washing machine; the hydraulic foot 800 includes a fixed part and a movable part, and a hollow chamber is formed between the fixed part and the movable part, and the hollow chamber is filled with a hydraulic medium: under pressure, the hydraulic medium The hollow chamber inside the hydraulic foot and / or the hollow chamber between the hydraulic feet can drive the movable part to expand and contract; the hydraulic foot 800 cooperates with the fixed foot 1000 to perform automatic leveling.

[0053] The basic principle of the washing machine in this embodiment is to determine a plane using three points. Fixed feet 1000 and hydraulic f...

Embodiment 2

[0074] Such as Figure 18 and Figure 19 As shown, a washing machine hydraulic leveling device in this embodiment includes a hydraulic foot 800. The hydraulic foot 800 includes a fixed part and a movable part. A hollow chamber is formed between the fixed part and the movable part. The hollow chamber is filled with hydraulic medium. The two hydraulic feet 800 are connected through the high-pressure oil pipe 700: under pressure, the hydraulic medium can circulate in the hollow chamber between the hydraulic feet 800 to drive the movable part to expand and contract to achieve automatic leveling.

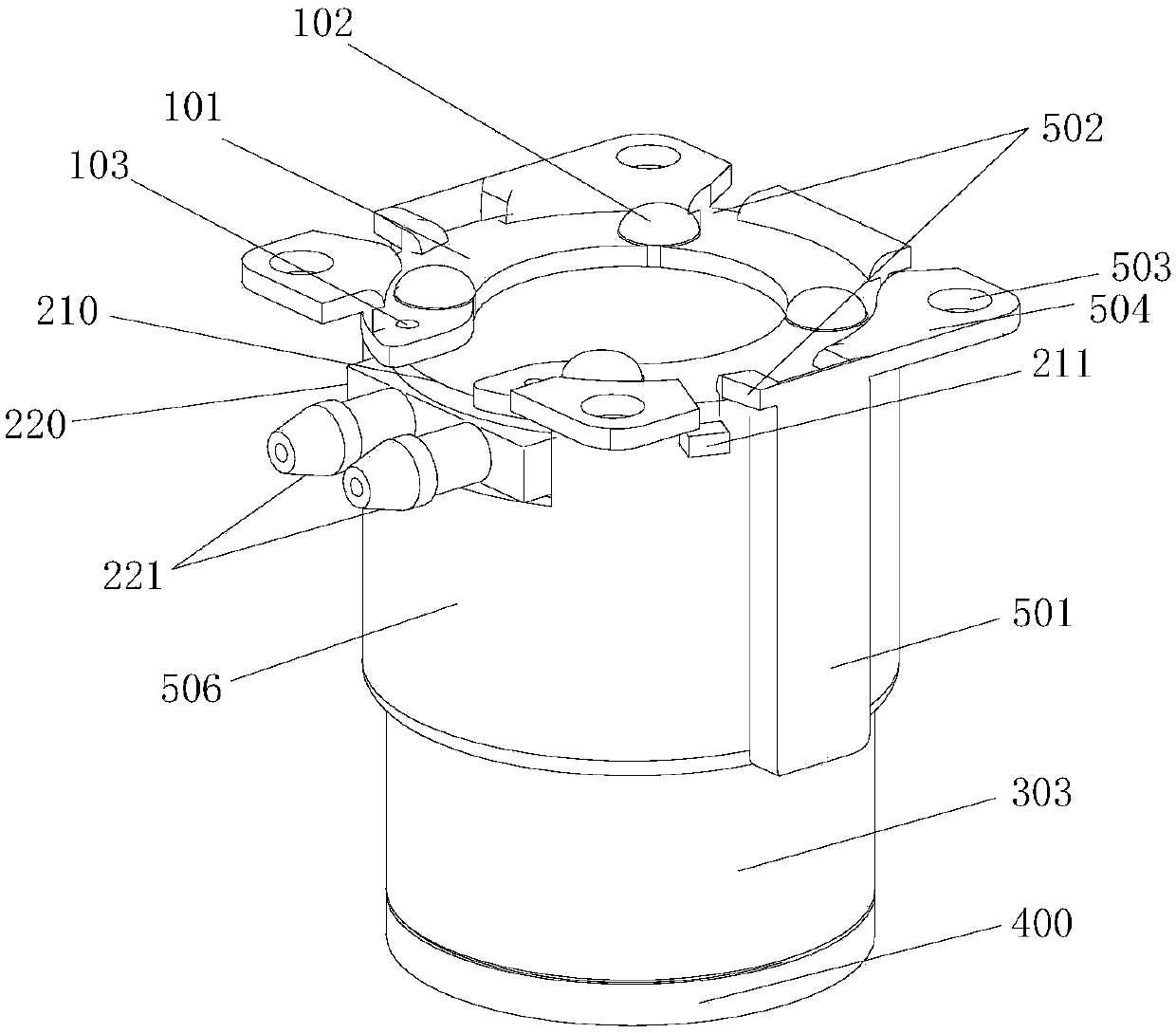

[0075] Such as Figure 20 As shown, the fixing part described in this embodiment is provided with an oil nipple 221 communicating with the hollow chamber, and the oil nipples 221 of the two hydraulic feet are respectively connected to the same connecting piece 1500 through the high-pressure oil pipe 700 to realize the communication between the two.

[0076] The hydraulic leveling devic...

Embodiment 3

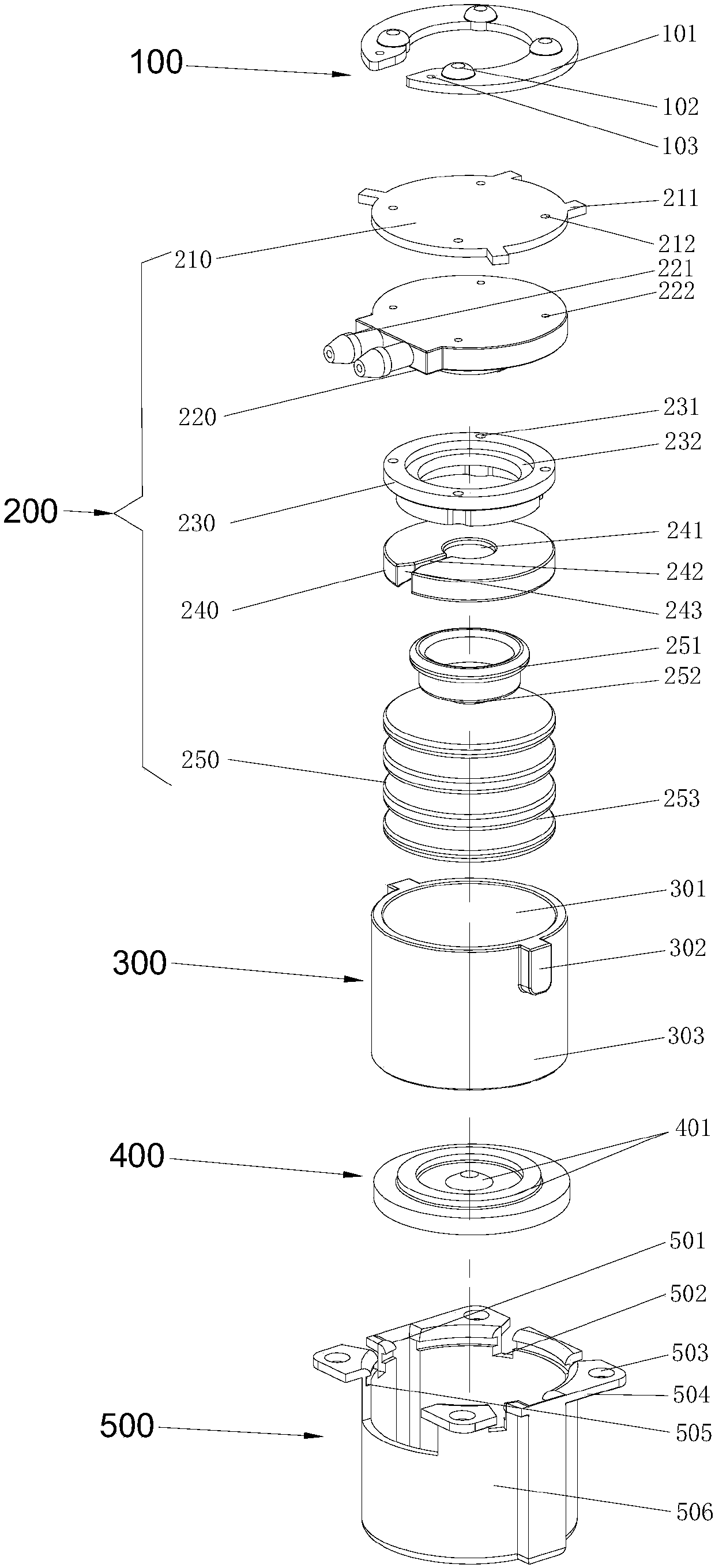

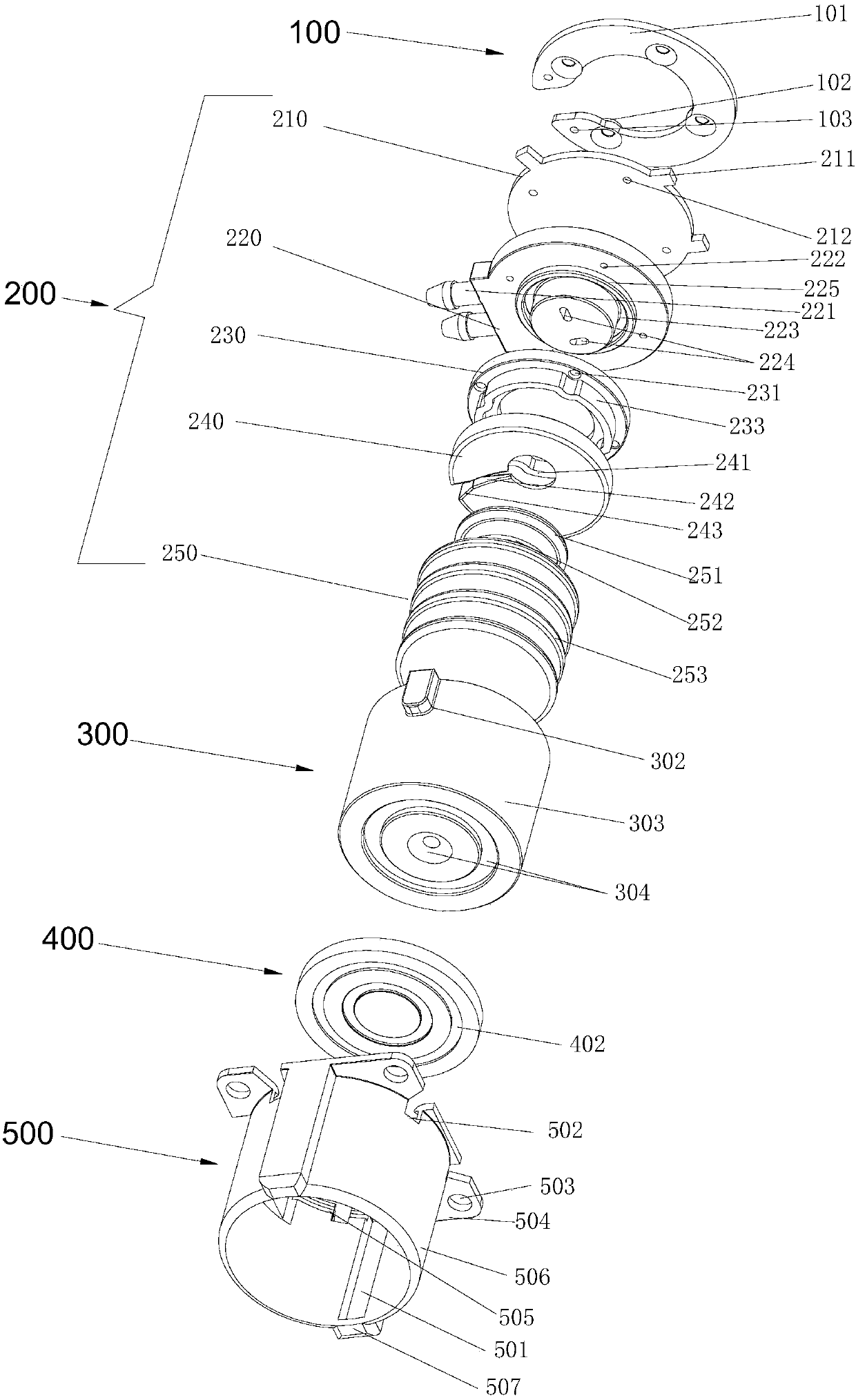

[0100] Such as Figure 1-8 As shown, the hydraulic foot of the present embodiment includes:

[0101] The sheath 500; the adjustment foot 300, which is arranged in the sheath 500 and can move axially relative to it; and the flexible body assembly 200, which is arranged in the adjustment foot 300 to accommodate the hydraulic medium; one end of the flexible body assembly 200 is limited Installed in the sheath 500, the other end is a telescopic end acting on the adjustment foot 300; the telescopic end of the flexible body assembly 200 expands and contracts under the action of the hydraulic medium to drive the adjustment foot 300 to move axially to achieve automatic leveling.

[0102] In this embodiment, the hydraulic feet are arranged on the four corners of the bottom plate of the washing machine or at least four are evenly arranged along the circumferential direction of the bottom plate, and at least two of the hydraulic feet are connected to each other: The feet are subjected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com